Automatic concrete curing device and method

A concrete and automatic technology, applied in the field of construction and civil engineering, can solve the problems of uneven maintenance quality of concrete, inability to ensure constant temperature state, inability to store water independently, etc., and achieve the effect of ensuring maintenance quality, high utilization efficiency, and good energy saving and environmental protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

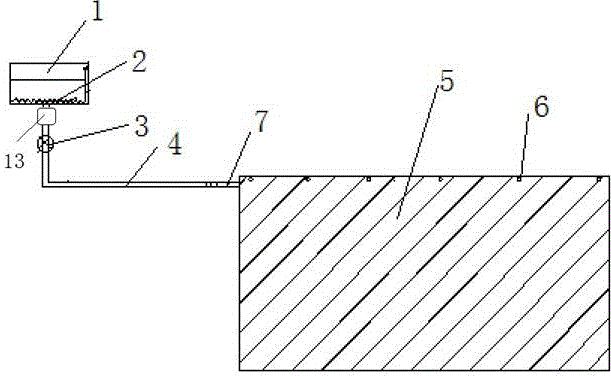

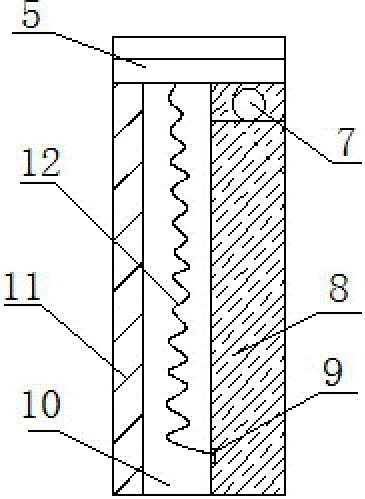

[0027] see figure 1 with figure 2 , an automatic concrete maintenance device, comprising a water tank 1, a heater 2, a temperature control switch and a curing curtain 5, the heater 2 and the temperature control switch are placed in the water tank 1, the temperature control switch is connected with the heater 2, and controls the heater 2 The opening and closing of the maintenance curtain 5 includes a moisture absorption layer 8, an anti-seepage layer 10 and a sun protection layer 11, and the protection sun protection layer 11 is arranged on one side of the moisture absorption layer 8, so that the moisture absorption layer 8 is positioned between the anti-seepage layer 10 and the protection sun protection layer 11 The moisture-absorbing layer 8 adopts geotextile with a thickness of 50mm, and a space for placing the micro-moisture tube 7 is sewn on the upper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com