Treatment device, treatment system and treatment method of reusing emulsion explosive waste propellants

A technology for emulsified explosive waste and processing equipment, which is applied in the direction of explosives, explosive composite components, explosive processing equipment, etc., can solve the problem of no safety risk and quality risk for emulsified explosive waste, and achieve the effect of safe treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

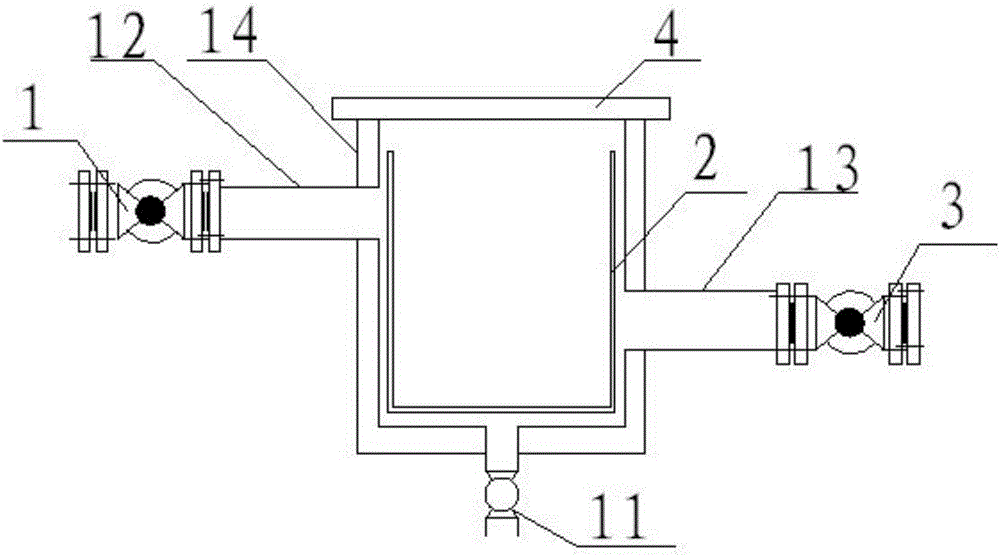

[0030] From attached figure 1 It can be seen that the treatment device for the reuse of emulsion explosive waste of the present invention comprises a storage tank 14, a filter screen 2, a sealing cover 4, an oil inlet part, and an oil outlet part; the filter screen 2 is arranged in the storage tank 14, and the sealing cover 4 covers On the storage tank 14 , the oil inlet part communicates with the upper part of the storage tank 14 , and the oil outlet part communicates with the lower part of the storage tank 14 .

[0031] In this way, after the emulsified explosive waste is dissolved in the oil phase material, it flows out from the oil outlet part for subsequent reprocessing. Wherein, the function of the filter screen used in the processing device of the present invention is to prevent hard impurities from entering into the subsequent system, thereby preventing safety risks and quality risks during processing. The device of the invention has its own filter, and the water-oil ...

Embodiment 2

[0033] In order to better ensure the filtering effect, as a preferred mode of the present invention, the mesh number of the filter screen 2 is 10-18 mesh.

Embodiment 3

[0035] From attached figure 1 It can be seen that the oil inlet part in the device includes the oil inlet branch pipeline 12, the inlet valve 1 arranged on the oil inlet branch pipeline 12, and the oil outlet part includes the oil outlet branch pipeline 13, and the outlet valve 3 arranged on the oil outlet branch pipeline 13; The inlet valve 1 is connected to the storage tank 14 through the oil inlet branch pipeline 12 , and the outlet valve 3 is connected to the storage tank 14 through the oil outlet branch pipeline 13 .

[0036] The oil phase material enters from the oil inlet part, fully dissolves the waste medicine in the filter screen, and the waste medicine dissolved in the oil phase material flows out from the oil outlet part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com