Self-repairing and force-response polyurethane material and preparation method thereof

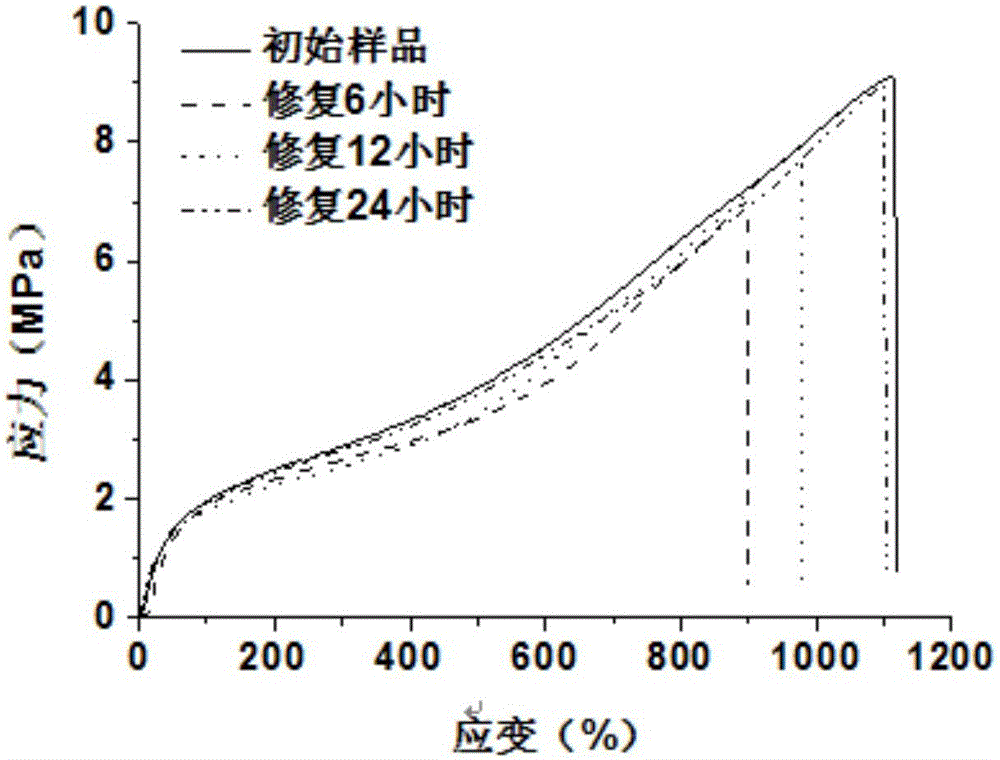

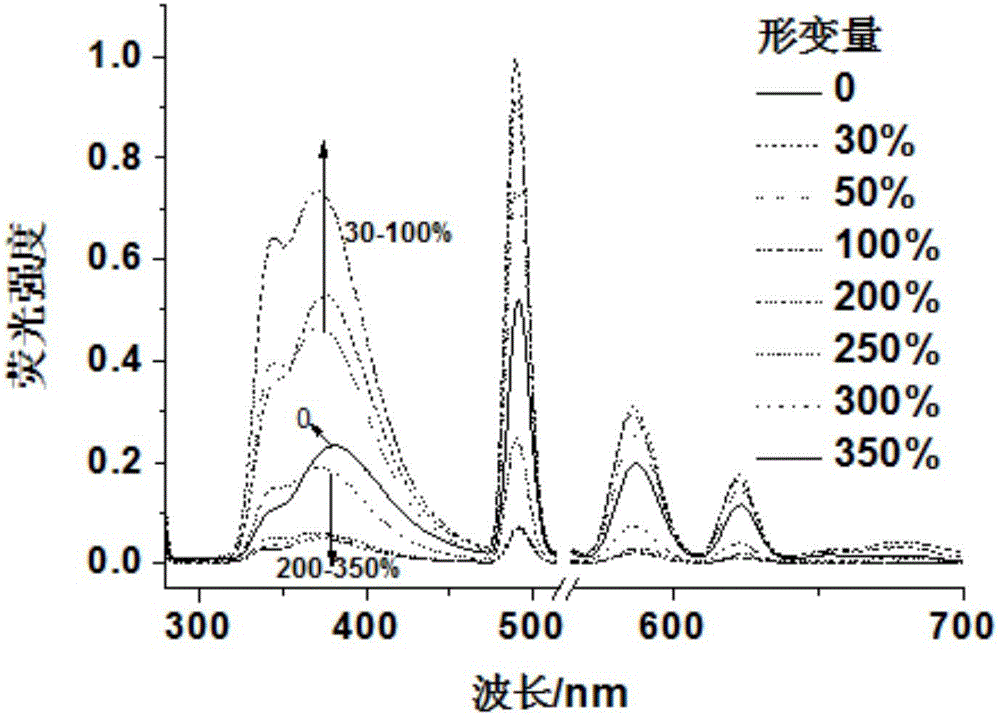

A polyurethane material and self-healing technology, applied in the field of polymer materials, can solve the problems of difficulty in ensuring the mechanical properties and self-healing properties of materials at the same time, difficult to find micro-cracks in materials, and complicated synthesis process, and achieve excellent self-repairing performance and cost. The effect of low and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

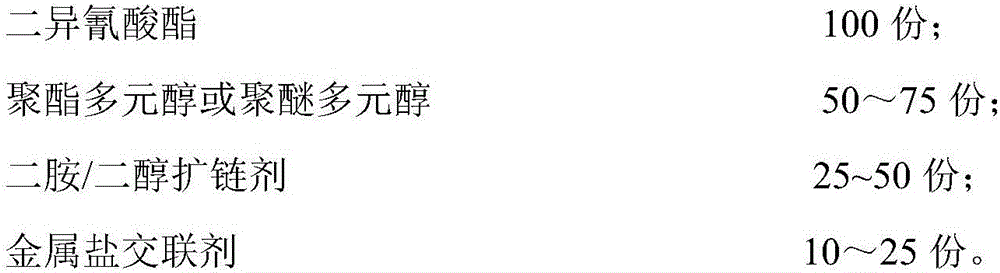

[0030] 100 parts of hexamethylene diisocyanate and 50 parts of polytetrahydrofuran ether glycol-1000 were melted and reacted at a temperature of 70°C for 3 hours to obtain a prepolymer, and then 50 parts of 2,6-diaminopyridine was added as a chain extender, and continued in the React at 70°C for 10 hours to obtain a ligand-containing polymer, and then precipitate and dry in methanol to obtain the product.

[0031] Dissolve the above 150 parts of ligand-containing polyurethane in 1500 parts of dichloromethane, add 25 parts of ferric chloride, stir at room temperature for 2 hours, and slowly evaporate the solvent to obtain a self-healing polyurethane material.

Embodiment 2

[0033] 100 parts of hexamethylene diisocyanate and 50 parts of polytetrahydrofuran ether glycol-1000 were melted and reacted at a temperature of 70~℃ for 3 hours to obtain a prepolymer, and then 50 parts of 2,6-diaminopyridine was added as a chain extender, and continued React at a temperature of 70° C. for 10 h to obtain a ligand-containing polymer, and then precipitate and dry in methanol to obtain the product.

[0034] Dissolve the above 150 parts of ligand-containing polyurethane in 1500 parts of dichloromethane, add 25 parts of zinc chloride, stir at room temperature for 2 hours, remove the solvent, and heat press at 120°C to obtain a self-healing material.

Embodiment 3

[0036] Melt 100 parts of hexamethylene diisocyanate and 50 parts of polytetrahydrofuran ether glycol-1000 at a temperature of 70°C for 3 hours to obtain a prepolymer, then add 50 parts of m-phenylenediamine as a chain extender, and continue to heat at a temperature of 70°C After reacting for 10 hours, a ligand-containing polymer was obtained, and then precipitated and dried in methanol to obtain the product.

[0037] Dissolve the above 150 parts of ligand-containing polyurethane in 1500 parts of dichloromethane, add 25 parts of ferric chloride, stir at room temperature for 2 hours, and slowly evaporate the solvent to obtain a self-healing polyurethane material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com