HDPE double-wall corrugated pipe and preparation method thereof

A double-wall corrugated pipe and ultrasonic technology, applied to chemical instruments and methods, pipes, rigid pipes, etc., can solve the problems of high brittleness of double-wall corrugated pipes, achieve good flexibility, good impact resistance, and improve impact resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

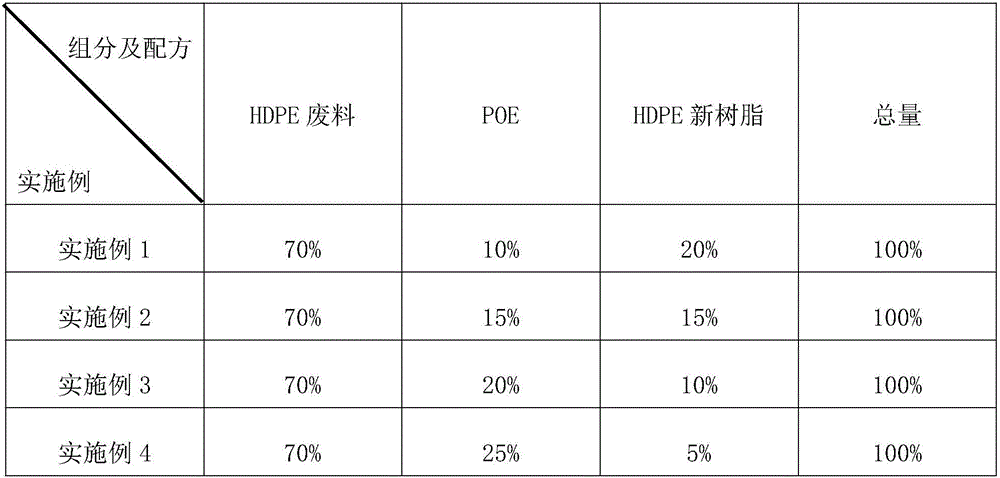

[0025] Embodiment 1-4: the preparation of HDPE return material, wherein the content of each component is as shown in Table 1:

[0026] A1: Select HDPE waste and cut off the heavily polluted part;

[0027] A2: Break the HDPE waste into 2-3mm particles, use ethanol as the medium, clean and remove the oil on the surface of HDPE in an ultrasonic cleaner with a power of 68kHZ, control the temperature of ultrasonic cleaning at 60-80°C, and rinse with water for 2-3 all over;

[0028] A3: After drying the HDPE waste, weigh the following raw materials according to the formula: HDPE waste, POE and HDPE new resin, and stir evenly;

[0029] A4: Put the uniformly stirred raw materials in A3 into the extruder to granulate to obtain HDPE regrind.

[0030] Wherein POE is ethylene-butene copolymer, wherein the proportion of butene segment is 30-35%.

[0031] Table 1: Composition Table in Embodiment 1-4

[0032]

Embodiment 5-20

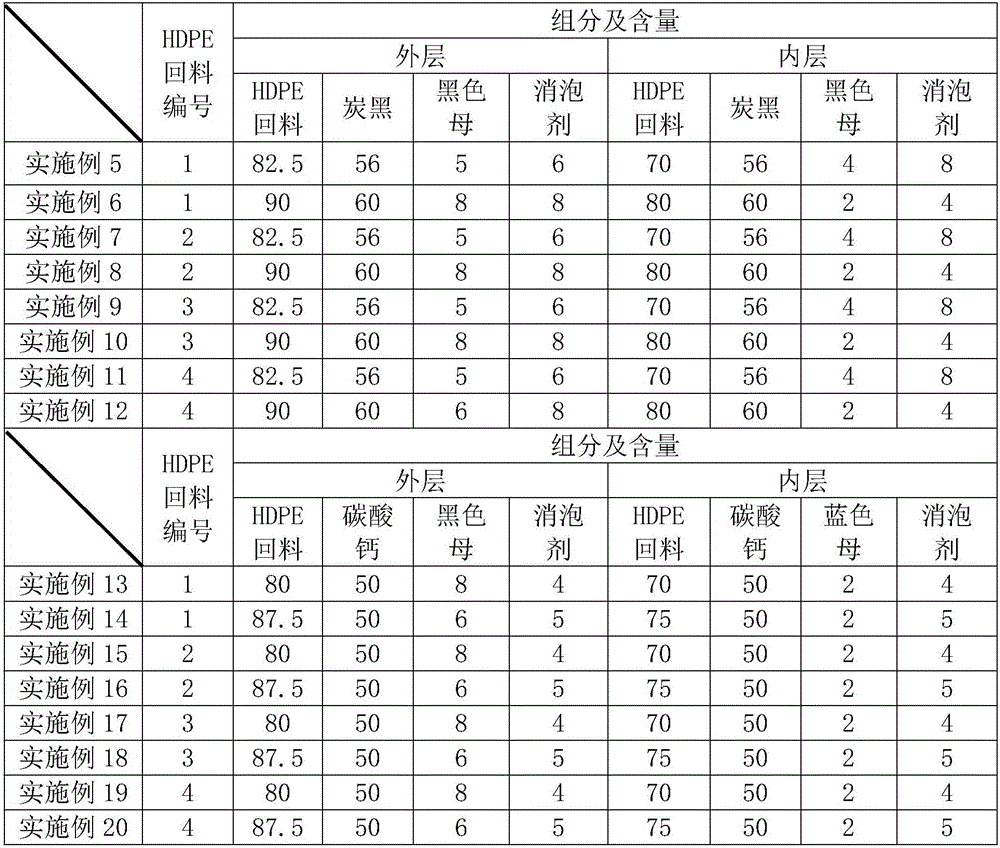

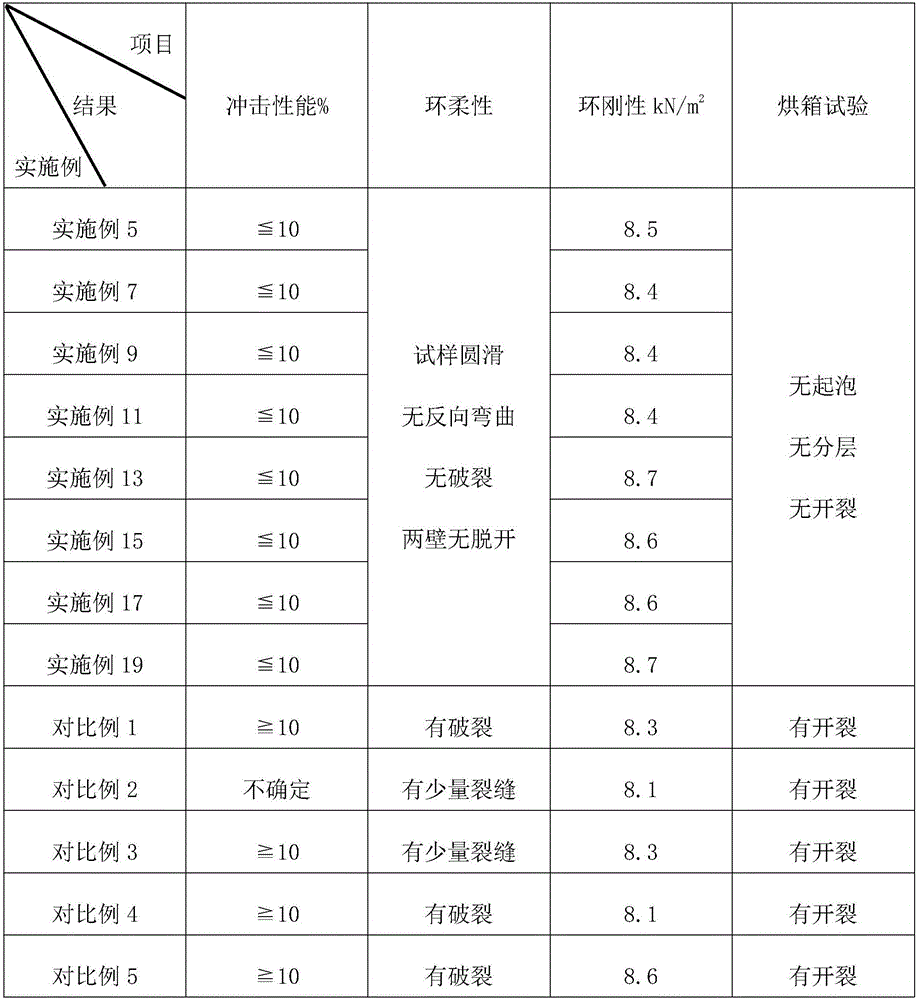

[0033] Example 5-20: Prepare a double-walled corrugated pipe of HDPE according to the following steps. For the content of each component in Example 5-20, see Table 2, wherein HDPE return number 1 represents the component content as shown in Example 1 As mentioned above, HDPE return number 2 represents the component content as described in Example 2, and so on.

[0034] A kind of preparation of HDPE double-wall corrugated pipe:

[0035] S1: Take the HDPE return material of the formula amount, pour it into the stirring device and stir;

[0036] S2: Add the filler under the condition of stirring, stir for 2 minutes after the addition, then add the color masterbatch and defoamer, stir for 4-5 minutes until uniform, put the evenly mixed mixture into the suction cylinder for standby;

[0037] S3: Turn on the power of the main engine, then turn on the single-screw extruder to heat, raise the temperature to 100-120°C at a rate of 5°C / min, then keep it warm for 2 hours, then raise the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com