Organic silicon modified epoxy resin optical packaging material composition

A technology of epoxy resin and encapsulation material, which is used in electrical components, circuits, semiconductor devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

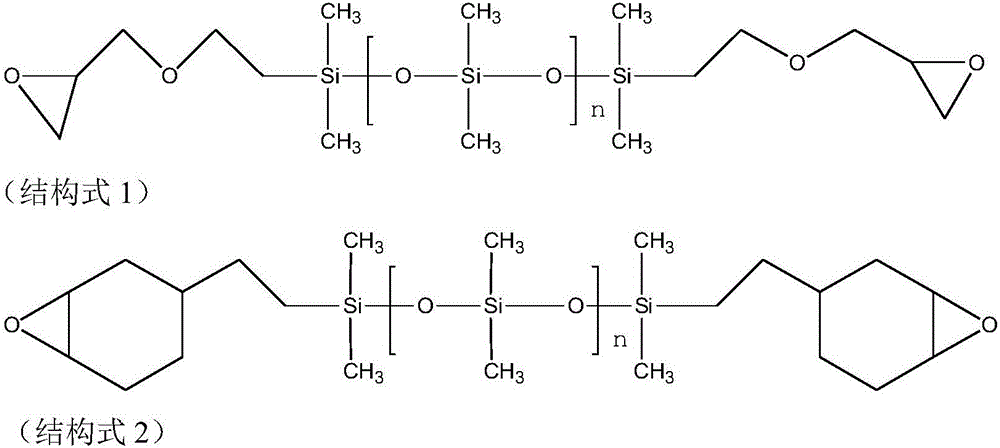

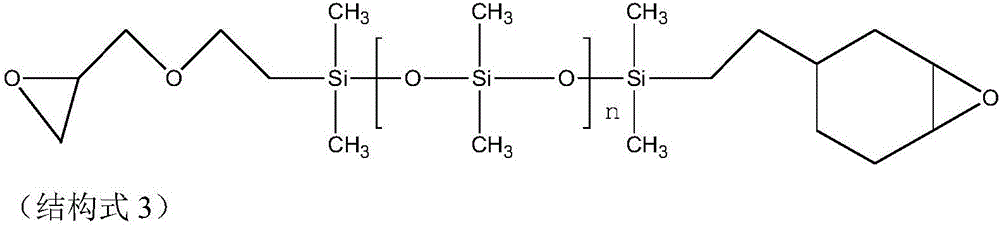

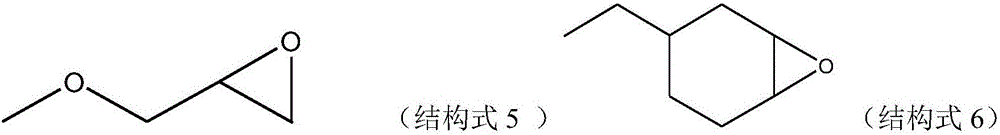

[0020] By weight, get organosilicon modified epoxy A (structural formula 1, wherein n=5) 200g, organosilicon modified epoxy resin B (structural formula 4, wherein a / b=0.7, R is structural formula 5) 300g, resist Add 0.2 g of oxidant (β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate) into the stirring tank, raise the temperature to 60°C, stir for 1 hour, and then cool with cooling water To 20° C., add 500 g of silicone-modified anhydride (structural formula 7, where n=1), 0.2 g of curing accelerator (triphenylphosphine), and stir evenly to obtain an epoxy resin mixture for optical encapsulation.

Embodiment 2

[0022] By weight, get organosilicon modified epoxy A (structural formula 2, wherein n=8) 300g, organosilicon modified epoxy resin B (structural formula 4, wherein a / b=1.5, R is structural formula 6) 350g, resist Add 0.4g of oxidizing agent (β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate) into the stirring tank, raise the temperature to 60°C, stir for 1 hour, then pass cooling water to cool To 20° C., add 500 g of silicone-modified anhydride (structural formula 7, where n=10), 0.3 g of curing accelerator (triphenylphosphine), and stir evenly to obtain an epoxy resin mixture for optical encapsulation.

Embodiment 3

[0024] By weight, get organosilicon modified epoxy A (structural formula 3, wherein n=10) 250g, organosilicon modified epoxy resin B (structural formula 4, wherein a / b=1.2, R is structural formula 5) 400g, resist Oxidant (butyryl toluate) 0.2g, put into the stirring tank, heat up to 60°C, stir for 1 hour, cool to 20°C with cooling water, add 700g of organosilicon-modified acid anhydride (structural formula 7, wherein n=15 ), 0.4 g of a curing accelerator (triphenylphosphine), and stir evenly to obtain an epoxy resin mixture for optical encapsulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com