Ultrahigh-temperature-resistant composite multi-soap-base self-restored bearing lubricating grease and preparation method thereof

A technology of bearing lubrication and multi-soap base, applied in lubricating compositions, petroleum industry, etc., can solve problems such as insufficient high temperature resistance, achieve good high temperature stability, high temperature extreme pressure anti-wear performance, and low high temperature evaporation loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

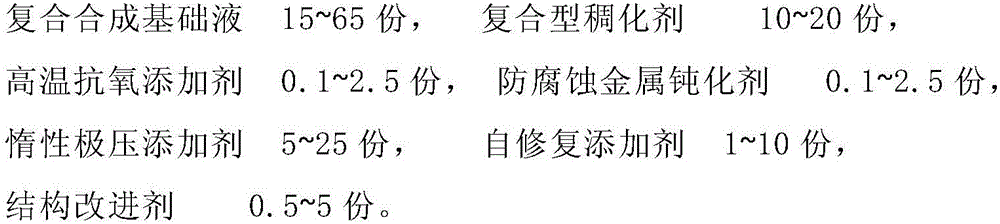

[0039] It is formulated by weight from the following components and contents of raw materials:

[0040]

[0041] Preparation:

[0042] Add 12 parts of synthetic polyol esters to the blending tank according to the metering, and evenly add 6 parts of synthetic polyphenyl esters under stirring. ℃, add 2 parts of alcohol, react for 30 minutes, continue to heat up to 100 ℃, stir to disperse, remove alcohol, the time is not less than 60 minutes, the preparation is completed, and it is ready to use;

[0043] Add 12 parts of PAO150 to the refining kettle according to the metering, and evenly add 6 parts of PAO20, 4 parts of alkylnaphthalene, and 2 parts of synthetic fluorinated polyether in a stirring state to mix evenly, heat and stir the refining kettle to 60 ° C, add 3 One part of calcium hydroxide powder, fully stirred, the time is not less than 40min, then add 1.5 parts of octanoic acid, the time is not less than 20min, then add 3 parts of 12-hydroxystearic acid, the time is ...

Embodiment 2

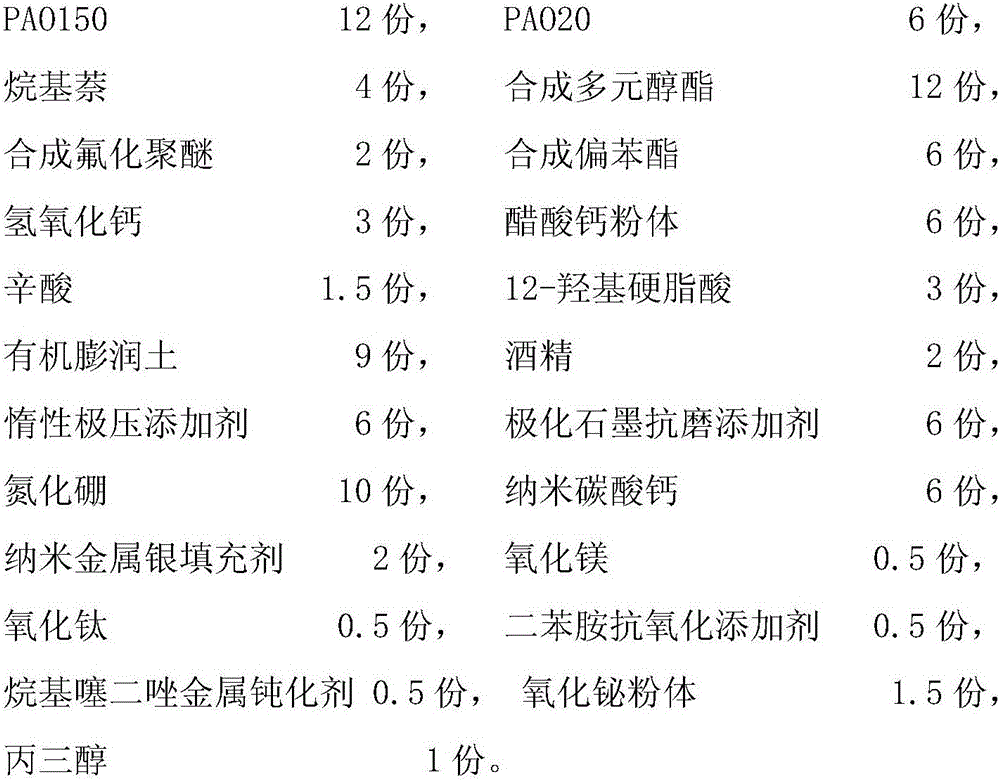

[0048] It is formulated by weight from the following components and contents of raw materials:

[0049]

[0050]

[0051] Preparation:

[0052] Add 6 parts of synthetic polyol esters to the blending tank according to the metering, and evenly add 12 parts of synthetic polyphenyl esters under stirring. ℃, add 1.5 parts of alcohol, react for 30 minutes, continue to heat up to 100 ℃, stir to disperse, remove alcohol, the time is not less than 60 minutes, the preparation is completed, and it is ready for use;

[0053] Add 15 parts of PAO150 into the refining kettle according to the metering, and evenly add 3 parts of PAO20, 3 parts of alkylnaphthalene, and 3 parts of synthetic fluorinated polyether in a stirring state to mix evenly, heat and stir the refining kettle to 60°C, and add 4 parts One part of calcium hydroxide powder, fully stirred, the time is not less than 40min, then add 1.5 parts of octanoic acid, the time is not less than 20min, then add 4 parts of 12-hydroxys...

Embodiment 3

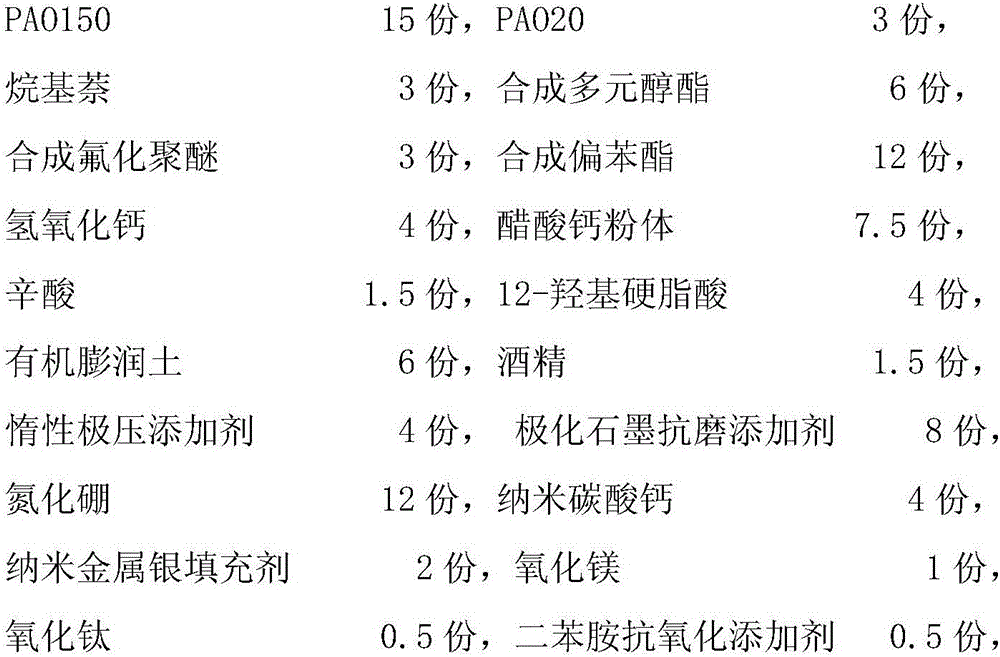

[0058] It is formulated by weight from the following components and contents of raw materials:

[0059]

[0060]

[0061] Preparation:

[0062] Add 9 parts of synthetic polyol esters to the blending kettle according to the metering, and evenly add 9 parts of synthetic polyphenylene esters under stirring. ℃, add 2.5 parts of alcohol, react for 30 minutes, continue to heat up to 100 ℃, stir to disperse, remove alcohol, the time is not less than 60 minutes, the preparation is completed, and it is ready for use;

[0063]Add 9 parts of PAO150 into the refining kettle according to the metering, and evenly add 9 parts of PAO20, 3 parts of alkylnaphthalene, and 3 parts of synthetic fluorinated polyether in a stirring state to mix evenly, heat and stir the refining kettle to 60 ° C, add 2.5 One part of calcium hydroxide powder, fully stirred, the time is not less than 40min, then add 1 part of octanoic acid, the time is not less than 20min, then add 2.5 parts of 12-hydroxysteari...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dropping point | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

| Dropping point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com