Method for low-temperature extraction of seabuckthorn seed oil, and compound product

A technology of sea buckthorn seed oil and sea buckthorn seeds is applied in the directions of oil/fat production, production of fat, edible oil/fat, etc., which can solve the problems of easy oxidation and low effective active components of compound oil products, and achieves high recovery rate and reduced Production cost, simple pretreatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

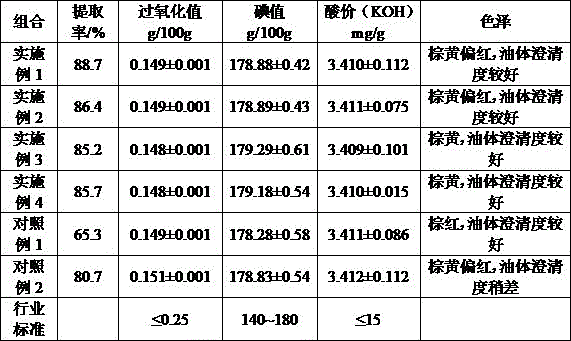

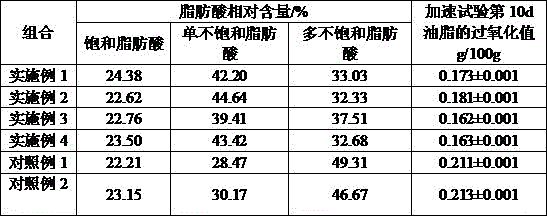

Embodiment 1

[0027] Remove impurities from seabuckthorn fruit seeds, rinse with water and drain, then dry in an oven at 45°C, use a roller to press seabuckthorn seeds to a pancake shape with a thickness of 0.02mm, weigh 500g, put it into an extraction bag and place In an extraction kettle with a capacity of 3L, and close the feed valve. Open the exhaust valve and exhaust the extraction kettle through a vacuum pump to ensure that the air in the kettle is completely removed and the pressure in the kettle is reduced to -0.5Mpa. Close the exhaust valve and open the liquid inlet valve. The 1,1,1,2-tetrafluoroethane solvent in the solvent tank is transported by a high-pressure plunger pump, and then heated to 55°C by a plate heat exchanger to make the 1,1,2-tetrafluoroethane solvent After the 1,2-tetrafluoroethane solvent reaches the subcritical state, inject it into the extraction kettle through the plunger pump, observe the liquid level through the sight glass until the solvent submerges the r...

Embodiment 2

[0029] The difference from Example 1 is that the seabuckthorn seeds are rinsed with water, drained, dried in an oven at 50°C, and pressed to a pancake shape with a thickness of 0.03mm by a rolling machine. The extraction pressure is 0.75MPa. The extraction time for 4 times is 90min, and the other conditions are the same. Under this condition, the yield of crude oil was 86.4%. The crude oil was centrifuged to remove impurities at 4°C and 16000 r / min to obtain the finished seed oil. The finished seabuckthorn seed oil is compounded, mixed, and bottled at a ratio of 45%, seabuckthorn fruit oil 40%, and olive oil 15%.

Embodiment 3

[0031] The difference from Example 2 is that the seabuckthorn seeds are rinsed with water, drained, put into an oven and dried at 40°C, and the thickness of the seabuckthorn seeds is pressed to a pancake shape of 0.01mm with a roller compactor. The 1,1,1 in the solvent tank , The 2-tetrafluoroethane solvent was heated to 50°C through a plate heat exchanger, the extraction pressure was 0.65 MPa, and the extraction time in the extraction tank was 60 minutes for three times, and other conditions were the same. Under this condition, the crude oil yield was 85.2%. The crude oil was centrifuged to remove impurities at 4°C and 16000 r / min to obtain the finished seed oil. The finished seabuckthorn seed oil is compounded, mixed, and bottled at a ratio of 55%, seabuckthorn fruit oil 40%, and olive oil 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com