Preparing method for novel environment-friendly low-temperature alloy

A low-temperature alloy and environmentally friendly technology, applied in the field of metallurgy, can solve the problems of expensive preparation, limited use range, high usage of indium, etc., and achieve a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

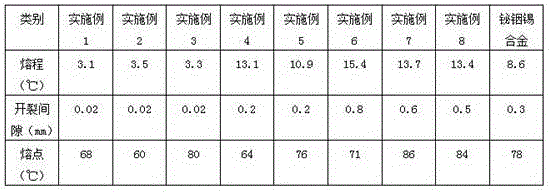

Examples

Embodiment 1

[0018] A preparation method of a novel environment-friendly low-temperature alloy:

[0019] Among them, the content of each element includes 45 parts of tin, 20 parts of bismuth, 18 parts of antimony, 2 parts of copper, 1.2 parts of cobalt, and 2.3 parts of manganese by weight ratio;

[0020] The preparation method comprises the following steps:

[0021] (1) Weigh tin, bismuth, and antimony according to the mass ratio, and mix them to obtain alloy powder, put the alloy powder into liquid paraffin, wherein the ratio of alloy powder mass to liquid paraffin volume is 1g:170ml, heat to 335°C, Heat preservation, after the alloy powder is completely melted, continue heat preservation and set aside;

[0022] (2) Weigh copper and manganese according to the ratio, first add copper to high-frequency induction furnace, heat to 1100°C, keep warm, make copper completely melted, then add manganese, after manganese is completely melted, continue to keep warm for 1 hour, Add 0.5 parts of di...

Embodiment 2

[0026] A preparation method of a novel environment-friendly low-temperature alloy:

[0027] Among them, the content of each element includes 30 parts of tin, 18 parts of bismuth, 15 parts of antimony, 3.5 parts of copper, 01.7 parts of cobalt, and 2.7 parts of manganese by weight ratio;

[0028] The preparation method comprises the following steps:

[0029] (1) Weigh tin, bismuth, and antimony according to the mass ratio, and mix them to obtain alloy powder, put the alloy powder into liquid paraffin, wherein the mass ratio of alloy powder to liquid paraffin is 1g:165ml, heat to 330°C, Heat preservation, after the alloy powder is completely melted, continue heat preservation and set aside;

[0030] (2) Weigh copper and manganese according to the ratio, first add copper to high-frequency induction furnace, heat to 1100°C, keep warm, make copper completely melted, then add manganese, after manganese is completely melted, continue to keep warm for 1 hour, Add 0.5 parts of diocty...

Embodiment 3

[0034] A preparation method of a novel environment-friendly low-temperature alloy:

[0035] Among them, the content of each element includes 60 parts of tin, 32 parts of bismuth, 27 parts of antimony, 1.5 parts of copper, 0.8 parts of cobalt, and 2.2 parts of manganese by weight ratio;

[0036] The preparation method comprises the following steps:

[0037] (1) Weigh tin, bismuth, and antimony according to the mass ratio, and mix them to obtain alloy powder, put the alloy powder into liquid paraffin, wherein the mass ratio of alloy powder to liquid paraffin is 1g:180ml, heat to 340°C, Heat preservation, after the alloy powder is completely melted, continue heat preservation and set aside;

[0038] (2) Weigh copper and manganese according to the ratio, first add copper to high-frequency induction furnace, heat to 1100°C, keep warm, make copper completely melted, then add manganese, after manganese is completely melted, continue to keep warm for 1 hour, Add 0.5 parts of dioctyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com