Sewing machine horizontal transmission shaft and machining method thereof

A technology of horizontal transmission shaft and processing method, which is applied in the field of sewing machine processing, can solve problems such as difficult breakthroughs in technology and difficulty in obtaining comprehensive performance horizontal transmission shaft, and achieve uniform distribution, simple and feasible processing method, and improved strength and hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

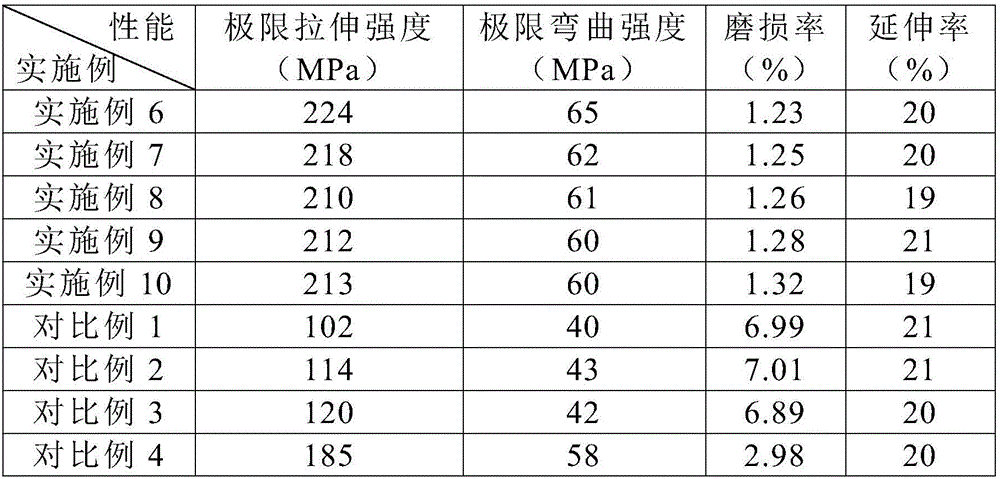

Examples

Embodiment 1

[0034] A horizontal transmission shaft of a sewing machine, the horizontal transmission shaft of a sewing machine is made by integrally molding an aluminum alloy substrate with nanopores on the surface and a ceramic, and the ceramic and the aluminum alloy substrate account for 10% and 90% of the total mass of the horizontal transmission shaft respectively; the aluminum alloy The matrix is composed of the following mass percentage components: Mg: 2.8%, Si: 1.6%, Cr: 0.56%, C: 1.4%, Cu: 0.16%, Mn: 0.16%, Zn: 0.18%, Ni: 0.5%, B: 0.2%, Zr: 0.07%, Sc: 0.09%, the balance is Al and unavoidable impurities; ceramics are SiC / Si 3 N 4 Composite ceramics, the composite ceramics include the following components in mass percentage: 4.2% C, 26% N, 10% Fe, 2.2% Y, and the balance is Si.

Embodiment 2

[0036] A horizontal transmission shaft of a sewing machine, the horizontal transmission shaft of a sewing machine is made by integral molding of an aluminum alloy substrate with nanopores on the surface and a ceramic, and the ceramic and the aluminum alloy substrate account for 8% and 92% of the total mass of the horizontal transmission shaft respectively; the aluminum alloy The matrix is composed of the following mass percentage components: Mg: 3.5%, Si: 1.5%, Cr: 0.55%, C: 1.5%, Cu: 0.15%, Mn: 0.18%, Zn: 0.16%, Ni: 0.3%, B: 0.12%, Zr: 0.06%, Sc: 0.10%, the balance is Al and unavoidable impurities; ceramics are SiC / Si 3 N 4 Composite ceramics, the composite ceramics include the following components in mass percentage: 3.5% C, 28% N, 8.8% Fe, 2.4% Y, and the balance is Si.

Embodiment 3

[0038] A horizontal transmission shaft of a sewing machine, the horizontal transmission shaft of a sewing machine is made by integrally molding an aluminum alloy substrate with nanopores on the surface and a ceramic, and the ceramic and the aluminum alloy substrate account for 12% and 88% of the total mass of the horizontal transmission shaft respectively; the aluminum alloy The matrix is composed of the following mass percentage components: Mg: 2.5%, Si: 1.8%, Cr: 0.6%, C: 1.2%, Cu: 0.18%, Mn: 0.15%, Zn: 0.20%, Ni: 1.2%, B: 0.24%, Zr: 0.08%, Sc: 0.08%, the balance is Al and unavoidable impurities; ceramics are SiC / Si 3 N 4 Composite ceramics, the composite ceramics include the following components in mass percentage: 5.2% C, 24.5% N, 10.5% Fe, 2.1% Y, and the balance is Si.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com