Multielement magnesium alloy anode material for water heaters and preparation method thereof

A technology of anode material and magnesium alloy, which is applied in the field of multi-component magnesium alloy anode materials for water heaters and its preparation, can solve the problems of affecting the protection effect of water heater liners, accelerating the corrosion consumption of anode materials, limited strength and electrochemical performance, etc. Protective effect, strength improvement, effect of guaranteed protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

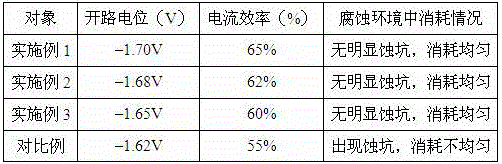

Examples

preparation example Construction

[0018] A method for preparing a multi-component magnesium alloy anode material for a water heater, comprising the following steps:

[0019] Step 1, take by weighing pure magnesium, pure aluminum, pure zinc, pure bismuth and pure antimony according to the mass percentage described in claim 1, the pure magnesium, pure aluminum and pure zinc that will weigh are put into corundum crucible for subsequent use;

[0020] Step 2, put the corundum crucible in step 1 in CO 2 +SF 6 Under the protection of mixed gas, heat until the pure magnesium, pure aluminum and pure zinc in the crucible are completely melted, then add pure bismuth and pure antimony, and continue heating to 710°C for later use;

[0021] Step 3: pour the mixed metal liquid prepared in step 2 into a steel mold preheated to 150°C in advance, and obtain the product after cooling and solidifying.

[0022] CO in the step 2 2 and SF 6 The volume ratio is 99:1.

Embodiment 1

[0025] A multi-element magnesium alloy anode material for a water heater is composed of the following components according to mass percentage: 3% Al, 6.0% Zn, 0.1% Bi and 0.1% Sb, and the balance is Mg and unavoidable impurities. The total amount of Si, Fe, Cu and Ni in impurities is less than 0.2%.

[0026] A method for preparing a multi-component magnesium alloy anode material for a water heater, comprising the following steps:

[0027] Step 1, weighing pure magnesium, pure aluminum, pure zinc, pure bismuth and pure antimony according to the above mass percentage, and putting the weighed pure magnesium, pure aluminum and pure zinc into a corundum crucible for subsequent use;

[0028] Step 2, put the corundum crucible in step 1 in CO 2 +SF 6 Under the protection of mixed gas, heat until the pure magnesium, pure aluminum and pure zinc in the crucible are completely melted, then add pure bismuth and pure antimony, and continue heating to 710°C for later use;

[0029] Step 3:...

Embodiment 2

[0032] A multi-component magnesium alloy anode material for a water heater is composed of the following components according to mass percentage: 3.5% Al, 6.5% Zn, 0.3% Bi and 0.3% Sb, and the balance is Mg and unavoidable impurities. The total amount of Si, Fe, Cu and Ni in impurities is less than 0.2%.

[0033] The preparation process of this embodiment is the same as that of Example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com