Device for preparing SiCxOy thin film through high-flux CVD

A silicon-carbon-oxygen, high-throughput technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as heavy workload and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below with reference to the accompanying drawings.

[0036] Fused silica glass is used as the substrate substrate for deposition, mainly because silicon carbide generally requires a higher deposition temperature during the deposition process, and the softening temperature of fused silica can reach above 1000°C, so it is SiC x o y The ideal substrate for thin film material deposition, as an option, flat glass can also be used as the substrate substrate.

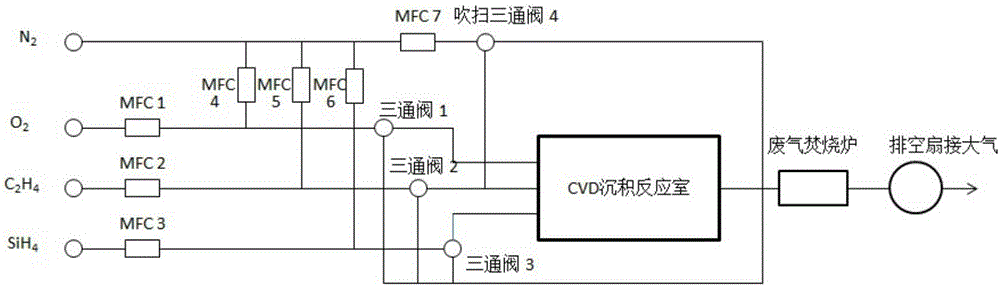

[0037] Reactive gas (O 2 , C 2 h 4 , SiH 4 ) and carrier gas (N 2 ) using 99.999% high-purity gas. At the same time, in order to ensure the quality of the CVD deposited coating, it is necessary to ensure an excellent airtightness between the entire gas delivery system and the atmosphere.

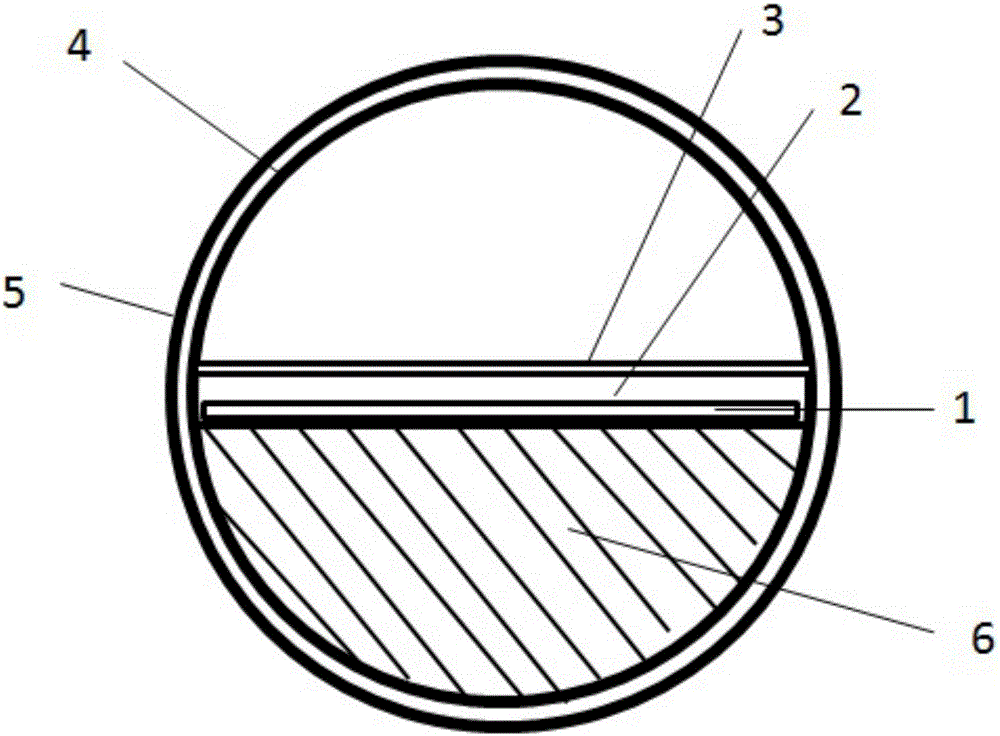

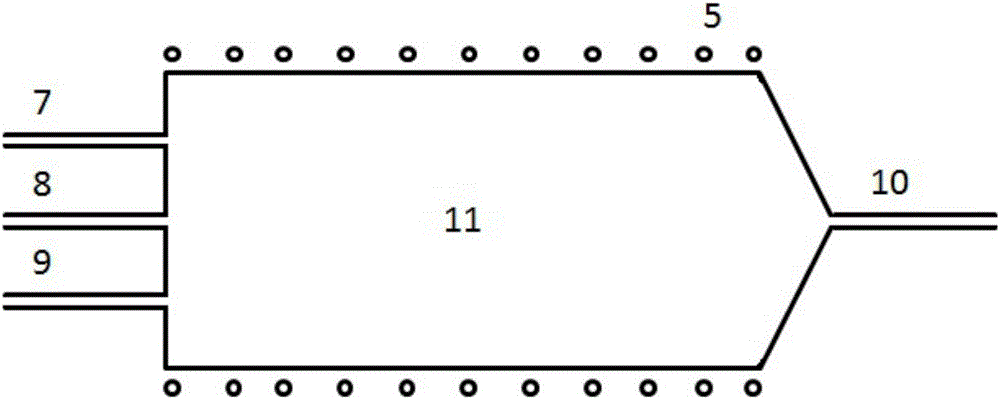

[0038] Such as figure 2 As shown, it is a cross-sectional view of the CVD deposition reaction chamber, 5 is a high-frequency induction coil, and its material is a copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com