Cold spraying welding method used for improving strength of dissimilar metal joints and based on interface pinning effect

A technology of dissimilar metal and joint strength, applied in metal material coating process, heating inorganic powder coating, coating and other directions, can solve the problem of limited interface bonding strength, improve mechanical and physical and chemical properties, increase bonding force, The effect of high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

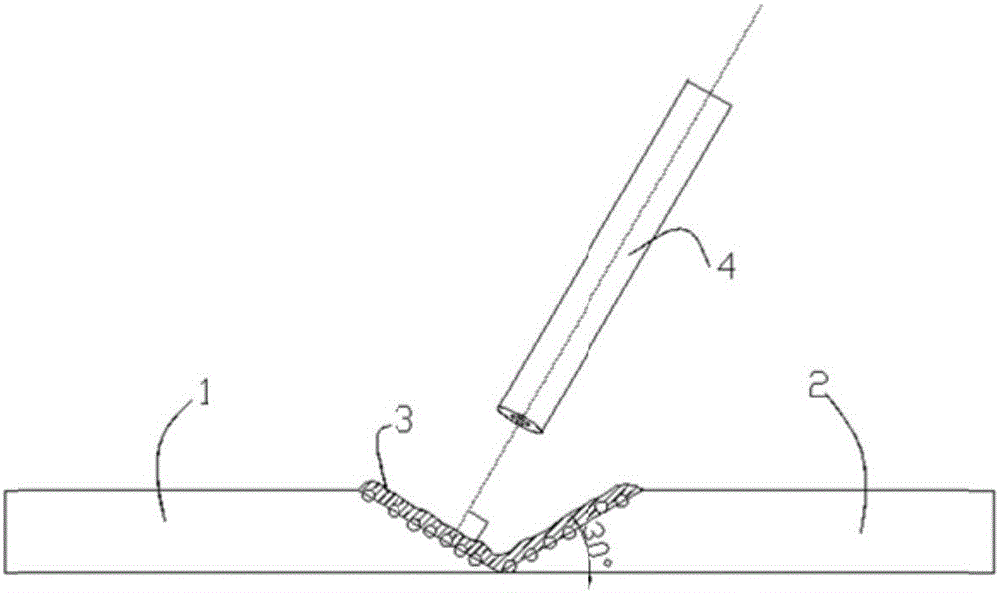

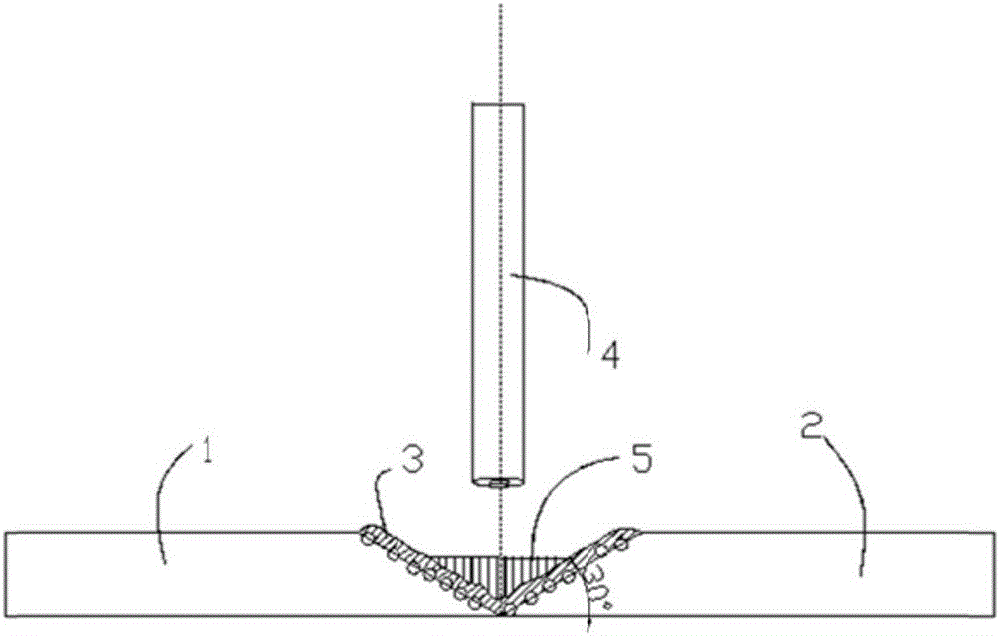

[0036] see figure 1 with figure 2 As shown, 50mm×40mm×8mm pure copper plate 1 and pure aluminum plate 2 are selected, the composite powder B is 70vol% pure copper powder with a diameter d50 of about 200 microns, 15vol% pure aluminum powder with a diameter d50 of about 50 microns and 15vol % pure copper powder with diameter d50 of about 50 microns, composite powder A is composed of 70vol% pure copper powder with diameter d50 of about 45 microns and 30vol% pure aluminum powder with diameter d50 of about 50 microns. Use 100-mesh quartz sand on the groove surface and sandblast the pressure at 6 atm; adjust the axial direction of the spray gun to be parallel to the surface normal of the pure aluminum plate 2 and the pure copper plate 1 to be connected, and spray composite powder B to form a composite coating of about 150 microns. Layer 3, such as figure 1 As shown; then adjust the spray gun axis to be perpendicular to the horizontal surface of the pure aluminum plate 2 and the p...

Embodiment 2

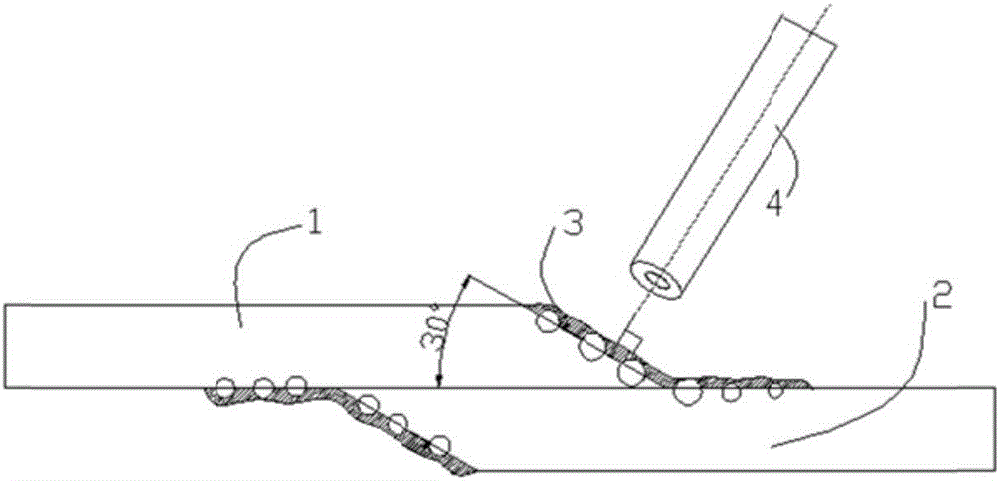

[0038] see image 3 with Figure 4 As shown, 50mm×100mm×3mm pure copper plate 1 and pure aluminum plate 2 are selected, the composite powder B is 30vol% pure copper powder with a diameter d50 of about 200 microns, 35vol% pure aluminum powder with a diameter d50 of about 50 microns and 35vol% pure copper powder with diameter d50 of about 50 microns, composite powder A is composed of 80vol% pure copper composite with diameter d50 of about 45 microns and 20vol% pure aluminum composite with diameter d50 of about 50 microns. Use 100-mesh quartz sand on the groove surface and sandblast the pressure at 6 atm; adjust the axial direction of the spray gun to be parallel to the surface normal of the pure aluminum plate 2 and the pure copper plate 1 to be connected, and spray composite powder B to form a composite coating of about 150 microns. Layer 3, such as image 3As shown; then adjust the axial direction of the spray gun and the pure aluminum plate 2 at an angle of 60° to spray the...

Embodiment 3

[0040] see Figure 5 with Image 6 As shown, a pure copper rod 11 and a pure aluminum rod 12 with a diameter of 5 mm and a length of 50 are selected, the composite powder B is 60vol% pure copper powder with a diameter d50 of about 200 microns, and 20 vol% with a diameter d50 of about 50 microns Pure aluminum powder and 20vol% pure copper powder with diameter d50 of about 50 microns, composite powder A is composed of 90vol% pure copper powder with diameter d50 of about 45 microns and 10vol% pure aluminum powder with diameter d50 of about 50 microns. Use 100-mesh quartz sand on the groove surface and sandblast the pressure at 6 atm; adjust the axial direction of the spray gun to be parallel to the surface normal of the pure copper rod 11 and the pure aluminum rod 12 to be connected, and spray composite powder B to form a 150-micron Composite coating3, such as Figure 5 Shown; Then adjust the axial direction of the spray gun to be perpendicular to the axis of the pure copper ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com