Finishing method of flame-retardant real silk fabric and application of finishing

A technology of silk fabrics and flame retardancy, which is applied in the field of finishing of flame-retardant silk fabrics, can solve the problems that cannot meet the requirements of flame-retardant textiles, and achieve good flame-retardant effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

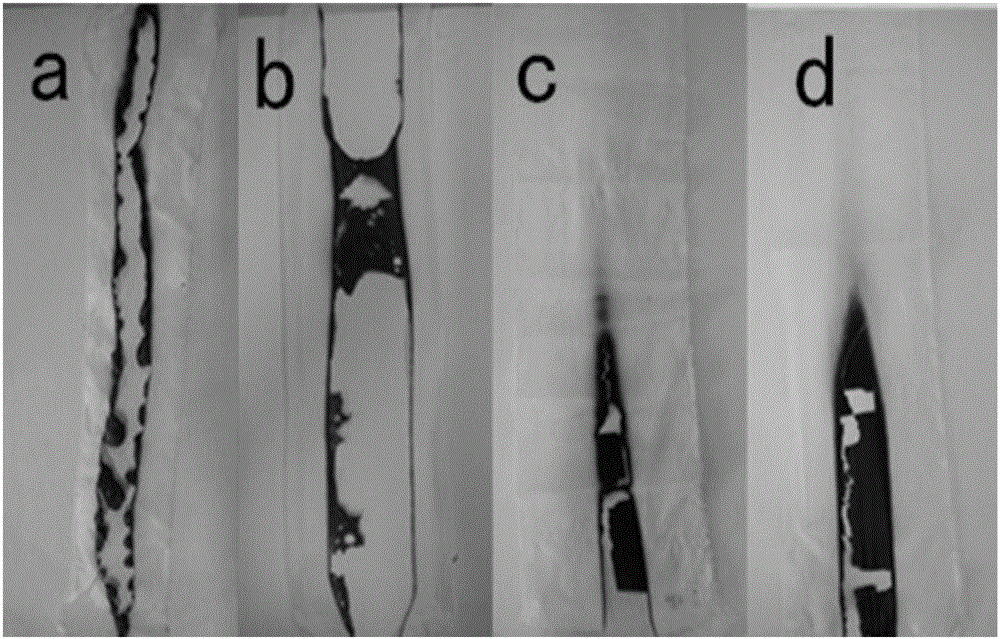

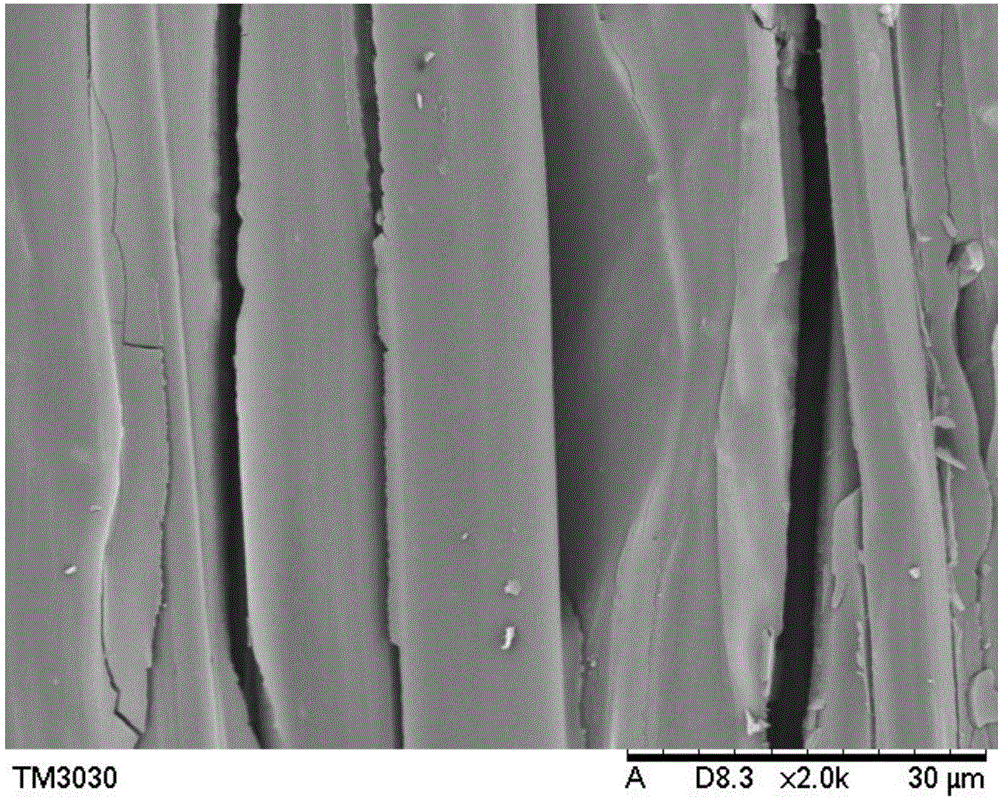

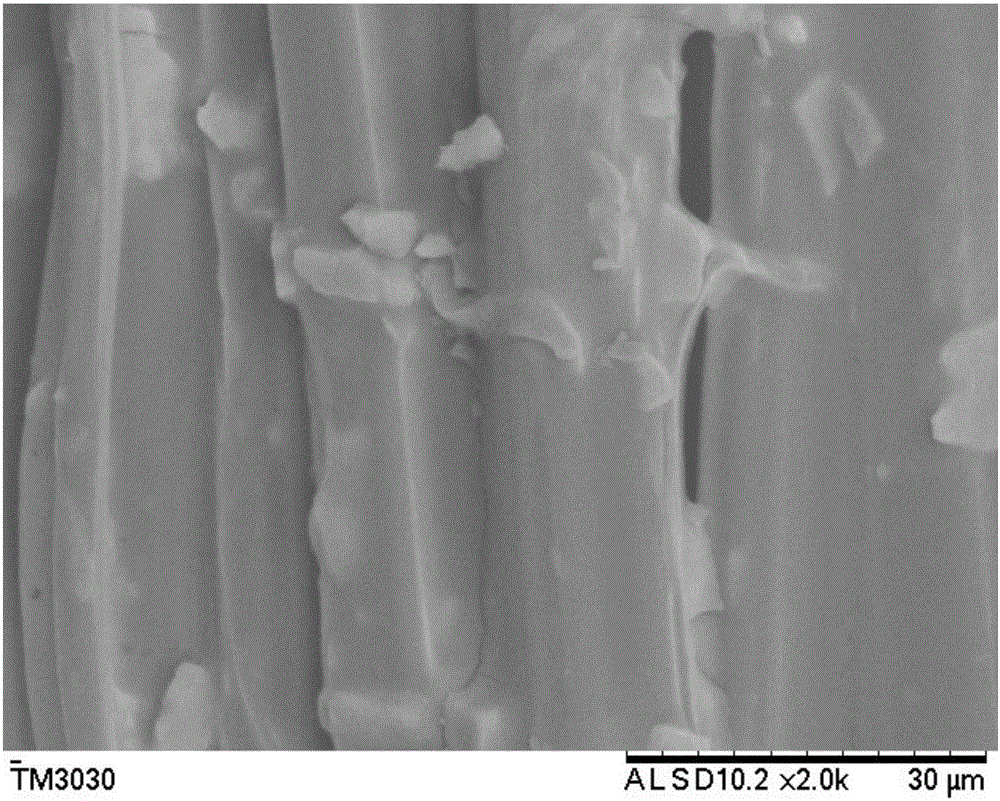

Image

Examples

Embodiment 1

[0027] Dissolve 4.5g of boron phosphate in 50mL of deionized water at 80°C, stir continuously until the solution is colorless, then add the dissolved mixed solution dropwise to 100mL of industrial silica sol, and react at 80°C for 3h , and finally the fabric is immersed in the prepared doped silica sol for 10 minutes, and is finished by the finishing process of two dipping and two rolling (residue rate 90% to 100%)→pre-baking at 80°C for 3 minutes→baking at 180°C for 3 minutes.

[0028] The fabric used in the present invention is real silk 10m / m electric spinning.

[0029] After testing, the limiting oxygen index of the finished silk fabric is 32.4%, and after 30 times of washing, the limiting oxygen index is 24.2%. in addition. In the fabric vertical burning test, the damaged length of the unfinished silk fabric is 30 cm, and the damaged length of the finished silk fabric is 11.7 cm.

Embodiment 2

[0031] Dissolve 4.5g of boron phosphate, 7.5g of citric acid monohydrate, 6g of tartaric acid, and 6.75g of sodium hypophosphite in 50mL of deionized water at 80°C until the solution is colorless, then add the dissolved mixed solution dropwise to 100mL of industrial Use silica sol, and react at 80°C for 3 hours, and finally immerse the fabric in the prepared doped silica sol for 10 minutes, and use two dipping and two padding (reduction rate 90% to 100%) → 80°C pre-baking 3min → 180°C baking 3min finishing process for finishing.

[0032] The fabric used in the present invention is real silk 10m / m electric spinning.

[0033] After testing, the limiting oxygen index of the finished silk fabric is 31.1%, and after 30 times of washing, the limiting oxygen index is 26.6%. in addition. In the fabric vertical burning test, the damaged length of the unfinished silk fabric is 30 cm, and the damaged length of the finished silk fabric is 12.9 cm.

Embodiment 3

[0035] Dissolve 4.5g of boron phosphate, 7.5g of citric acid monohydrate, 3g of tartaric acid, and 6.75g of sodium hypophosphite in 50mL of deionized water at 80°C until the solution is colorless, then add the dissolved mixed solution dropwise to 100mL of industrial Use silica sol, and react at 80°C for 3 hours, and finally immerse the fabric in the prepared doped silica sol for 10 minutes, and use two dipping and two padding (reduction rate 90% to 100%) → 80°C pre-baking 3min → 180°C baking 3min finishing process for finishing.

[0036] The fabric used in the present invention is real silk 10m / m electric spinning.

[0037] After testing, the limiting oxygen index of the finished silk fabric is 28.9%. After 30 times of washing, the limiting oxygen index is 25.8%. In the fabric vertical burning test, the damaged length of the finished silk fabric is 14.3cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com