Resist agent for blueprint cloth, and preparation method thereof

A technology of anti-dyeing agent and printed cloth, which is applied in the field of anti-dyeing agent, and can solve the problems of low adhesion rate of anti-dyeing agent and stiffness of blue printed cloth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

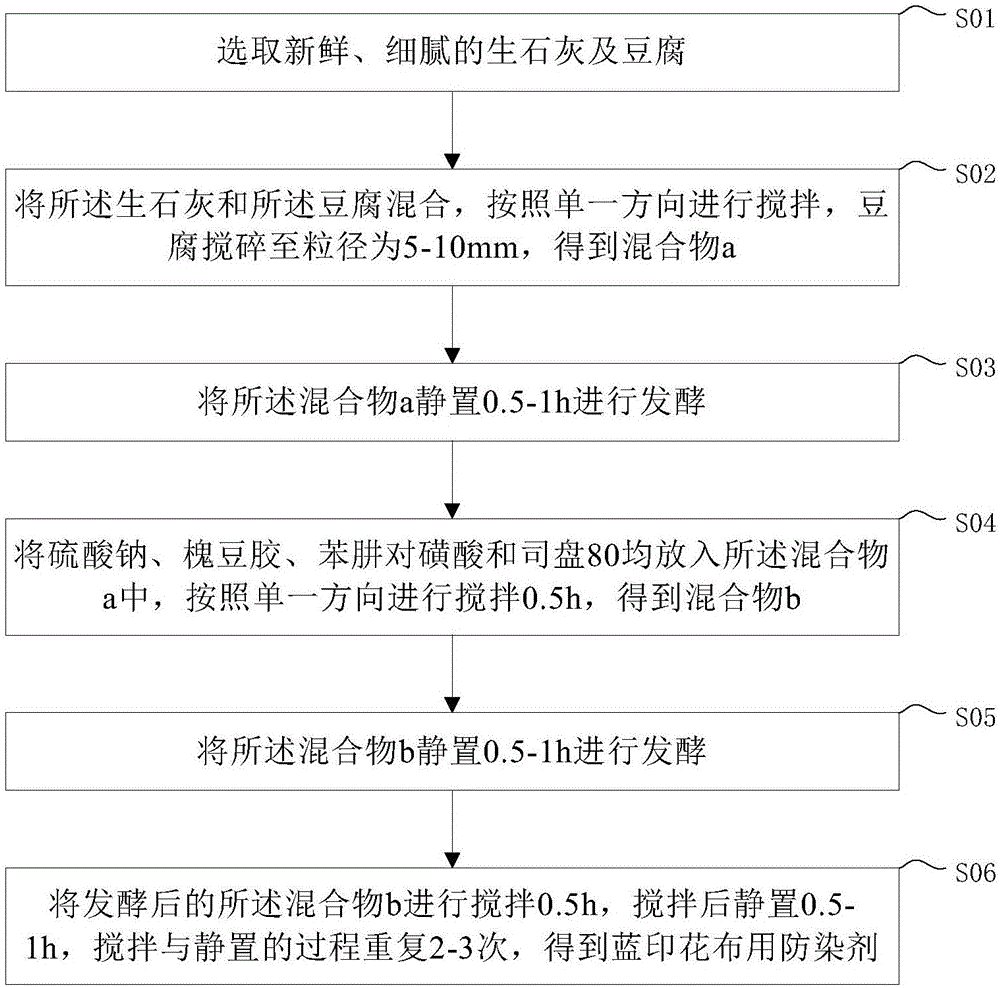

Image

Examples

Embodiment 1

[0025] The embodiment of the present invention provides a kind of anti-staining agent for blue calico, said anti-staining agent comprises 15 parts of quicklime, 25 parts of tofu, 3 parts of sodium sulfate, 8 parts of locust bean gum, and 3 parts of phenylhydrazine in parts by weight. Sulfonic acid and 10 parts Span 80.

[0026] The embodiment of the present invention also provides a preparation method of a resist for blue calico, the preparation method comprising:

[0027] S101: select fresh and delicate quicklime, fold the quicklime in half with a screen window and screen the quicklime; select fresh and delicate tofu;

[0028] S102: Mix the quicklime and the tofu, stir in a single direction, and crush the tofu until the particle size is 5mm, to obtain a mixture a;

[0029] S103: leave the mixture a for 1 hour to ferment;

[0030] S104: Put sodium sulfate, locust bean gum, phenylhydrazine p-sulfonic acid and Span 80 into the mixture a, and stir for 0.5 h in one direction to ...

Embodiment 2

[0034] The embodiment of the present invention provides a kind of anti-staining agent for blue calico, said anti-staining agent comprises 10 parts of quicklime, 20 parts of tofu, 5 parts of sodium sulfate, 5 parts of locust bean gum, and 3 parts of phenylhydrazine in parts by weight. Sulfonic acid and 5 parts Span 80.

[0035] The embodiment of the present invention also provides a preparation method of a resist for blue calico, the preparation method comprising:

[0036] S201: Select fresh and delicate quicklime and tofu;

[0037] S202: Mix the quicklime and the tofu, stir in a single direction, and crush the tofu until the particle size is 10 mm, to obtain a mixture a;

[0038] S203: leave the mixture a for 0.5h to ferment;

[0039] S204: Put sodium sulfate, locust bean gum, phenylhydrazine p-sulfonic acid, and Span 80 into the mixture a, and stir for 0.5 h in one direction to obtain mixture b;

[0040] S205: leave the mixture b for 0.5h to ferment;

[0041] S206: Stir t...

Embodiment 3

[0043] The embodiment of the present invention provides a kind of anti-staining agent for blue calico, said anti-staining agent comprises 20 parts of quicklime, 30 parts of tofu, 2 parts of sodium sulfate, 10 parts of locust bean gum, 1 part of phenylhydrazine in parts by weight. Sulfonic acid and 7 parts Span 80.

[0044] The embodiment of the present invention also provides a preparation method of a resist for blue calico, the preparation method comprising:

[0045] S301: select fresh and delicate quicklime, fold the quicklime in half with a screen window and screen the quicklime; select fresh and delicate tofu;

[0046] S302: Mix the quicklime and the tofu, stir in one direction, and crush the tofu until the particle size is 8mm, to obtain a mixture a;

[0047] S303: leave the mixture a for 1 hour to ferment;

[0048]S304: Put sodium sulfate, locust bean gum, phenylhydrazine p-sulfonic acid, and Span 80 into the mixture a, and stir for 0.5 h in one direction to obtain mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com