Auxiliary hole-guiding method facilitating driving of hard-rock-layer steel plate pile

A technology of steel sheet piles and rock formations, which is applied in the field of production auxiliary references, can solve the problems of not reaching the required depth of the cofferdam, the difficulty of driving steel sheet piles into hard rock formations, and limited use, so as to achieve improved physical and mechanical properties, efficient installation, The effect of good hole quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

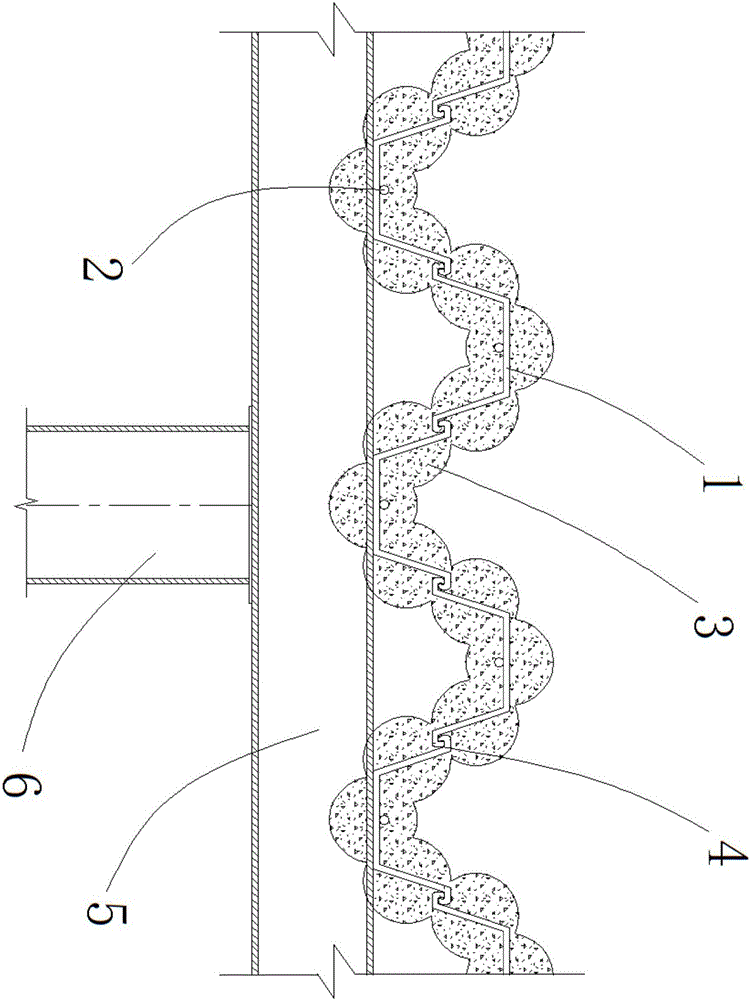

[0030] refer to Figure 1 to Figure 5 , the present invention is a kind of auxiliary hole introduction method that is convenient for driving steel sheet piles in hard rock layer, it is characterized in that comprising the following steps:

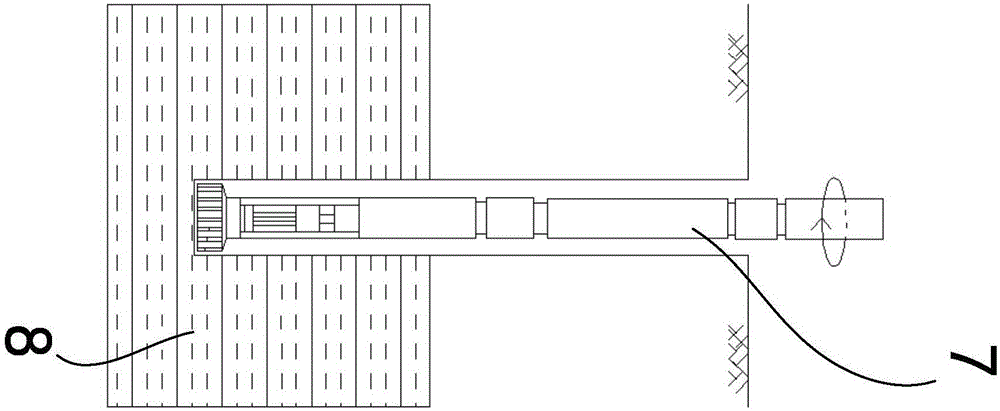

[0031] 1), according to the drawing, carry out the pile position measuring and releasing down-the-hole hammer 7;

[0032] 2), correct the levelness and verticality of the down-the-hole hammer 7 on the pile position;

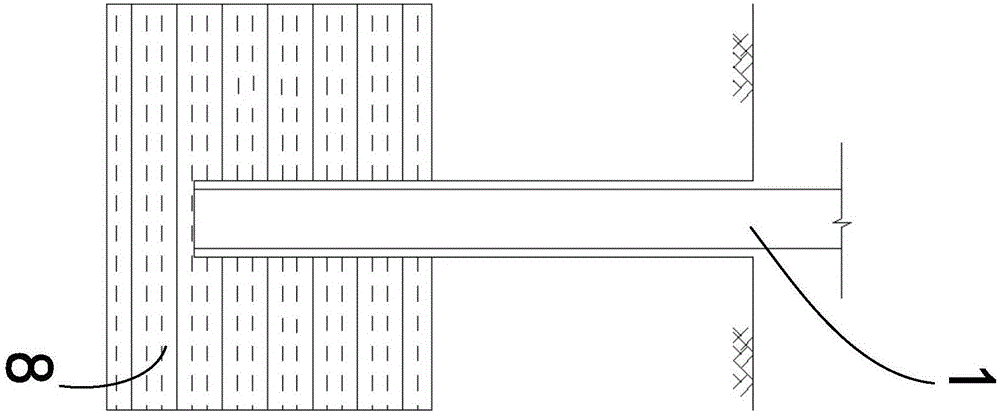

[0033] 3) Use the down-the-hole hammer 7 to drill a number of lead holes 3 at the position marked on the drawing, and the down-the-hole hammer 7 keeps spinning when impacting the hard rock layer 8, so that two adjacent lead holes 3 intersect to form a continuous groove;

[0034] 4) Drive several steel sheet piles 1 into the groove to the calibrated depth in sequence, so that each steel sheet pile 1 forms a wall;

[0035] 5), the purlin 5 supporting the steel sheet pile 1 is arranged on the inner side of the wall;

[0036] 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com