A method for preventing corrosion of transmission tower feet

A transmission tower tower, transmission tower technology, applied in the direction of towers, building types, buildings, etc., can solve the problem that the anti-corrosion method is difficult to meet the long-term service requirements of the transmission tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

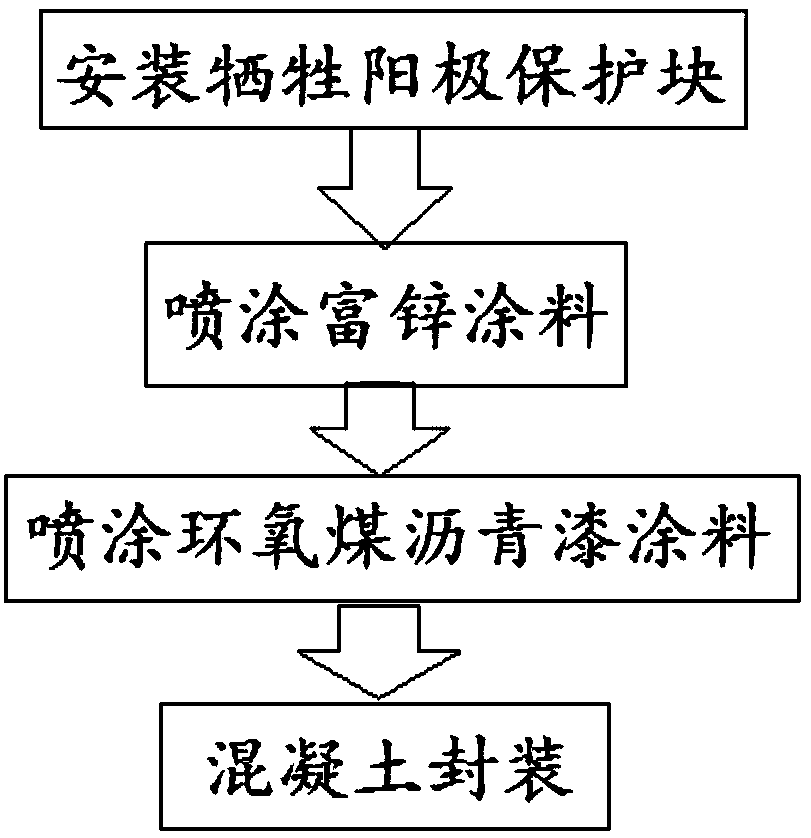

[0030] Such as figure 1 As shown, the anti-corrosion method of the tower foot of the transmission tower is divided into four steps:

[0031] 1. Install a sacrificial anode protection block around the foot of the transmission tower, which is composed of zinc or zinc alloy sacrificial anode metal and strip steel. The sacrificial anode metal is melted and cast on the strip steel, and the strip steel is welded and installed around the foot of the transmission tower, a total of four pieces. During the operation of the tower foot of the transmission tower, due to cathodic protection, the size of the sacrificial anode zinc block is about 110mm-130mm in length, 20mm-40mm in width, and 20-40mm in height, such as figure 2 shown.

[0032] 2. After the installation of the sacrificial anode block is completed, the tower foot of the transmission tower is sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com