Multi-functional drilling machine

A multi-functional drilling rig technology, applied in rotary drilling rigs, earthwork drilling, drilling equipment, etc., can solve problems such as unguaranteed construction quality, inability to meet design requirements, and inflexible equipment, so as to improve the working environment of workers and achieve ideal results , Improve the effect of the ability to destroy the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

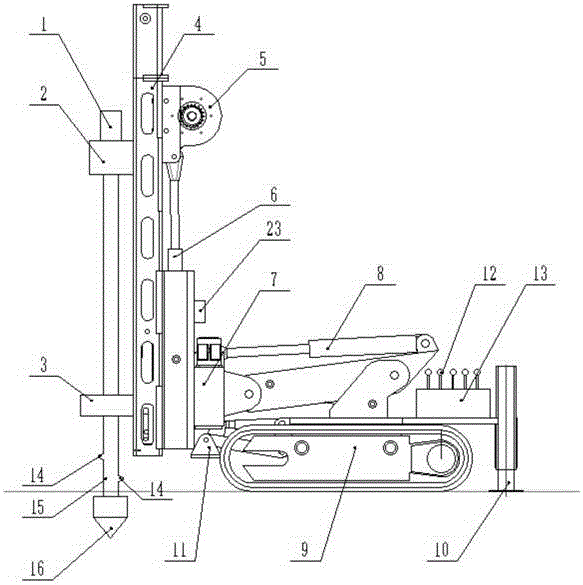

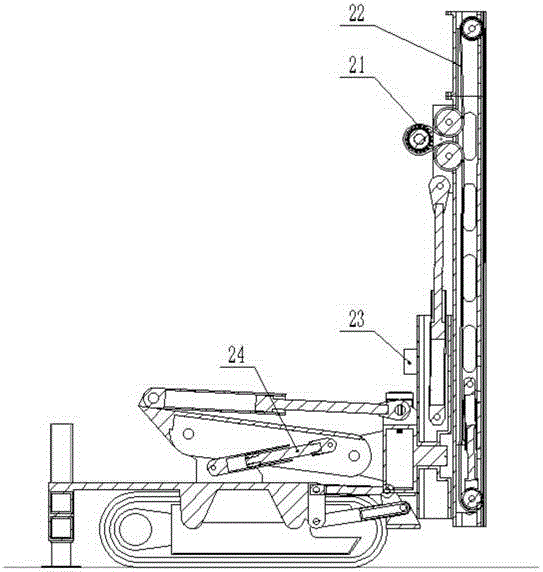

[0035] The technical solutions of the present invention will be exemplarily described below in conjunction with the accompanying drawings in the embodiments, but the present invention is not limited by the following embodiments, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

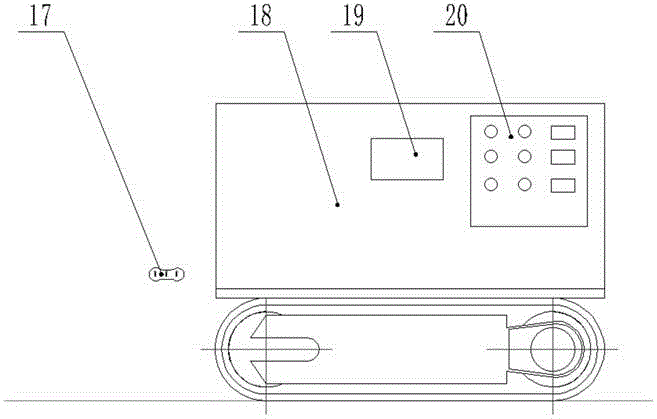

[0036] The utility model relates to a multifunctional drilling rig, which is a rotary spraying, swinging spraying and fixed spraying equipment between pile foundations in a small underground space, including three parts: an electric control system, a hydraulic system and an execution system.

[0037] The electric control system includes a remote controller 17, an instrument panel 20 and a verticality detection controller 23;

[0038] The hydraulic system provides the hydraulic power and electric control power of the whole set of equipment;

[0039] The execution system includes deflector 1, power head 2, gripper 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com