Continuously-variable rocker type valve mechanism

A valve mechanism and rocker arm type technology, which is applied in the field of continuously variable rocker arm type valve mechanism, can solve the problems that the fuel economy and power performance of the engine cannot reach the best effect, and achieve guaranteed power transmission, simple structure, and stability easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

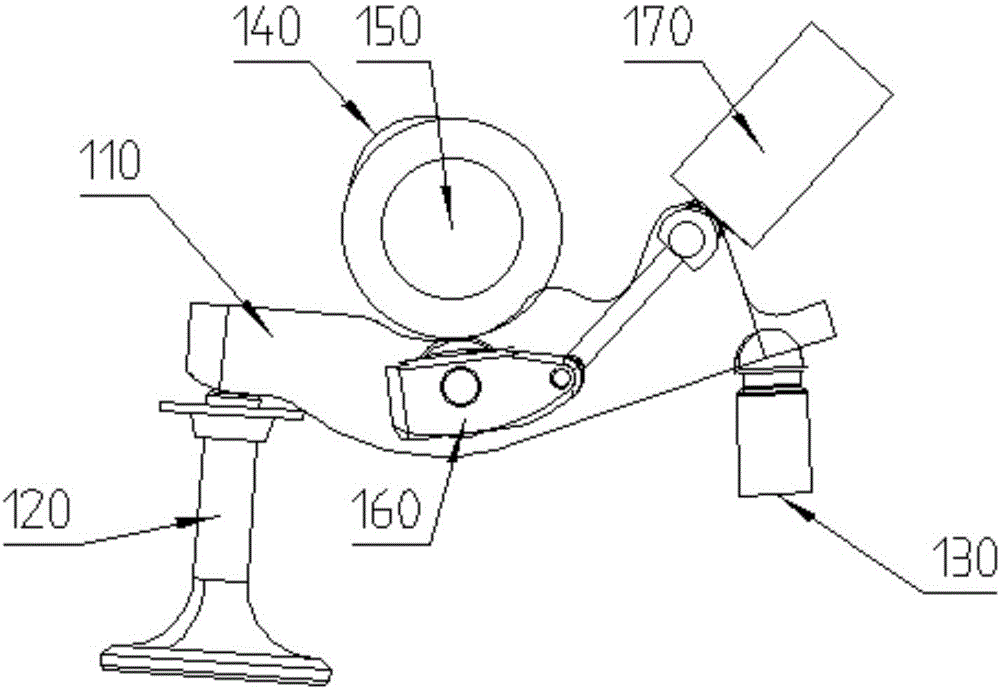

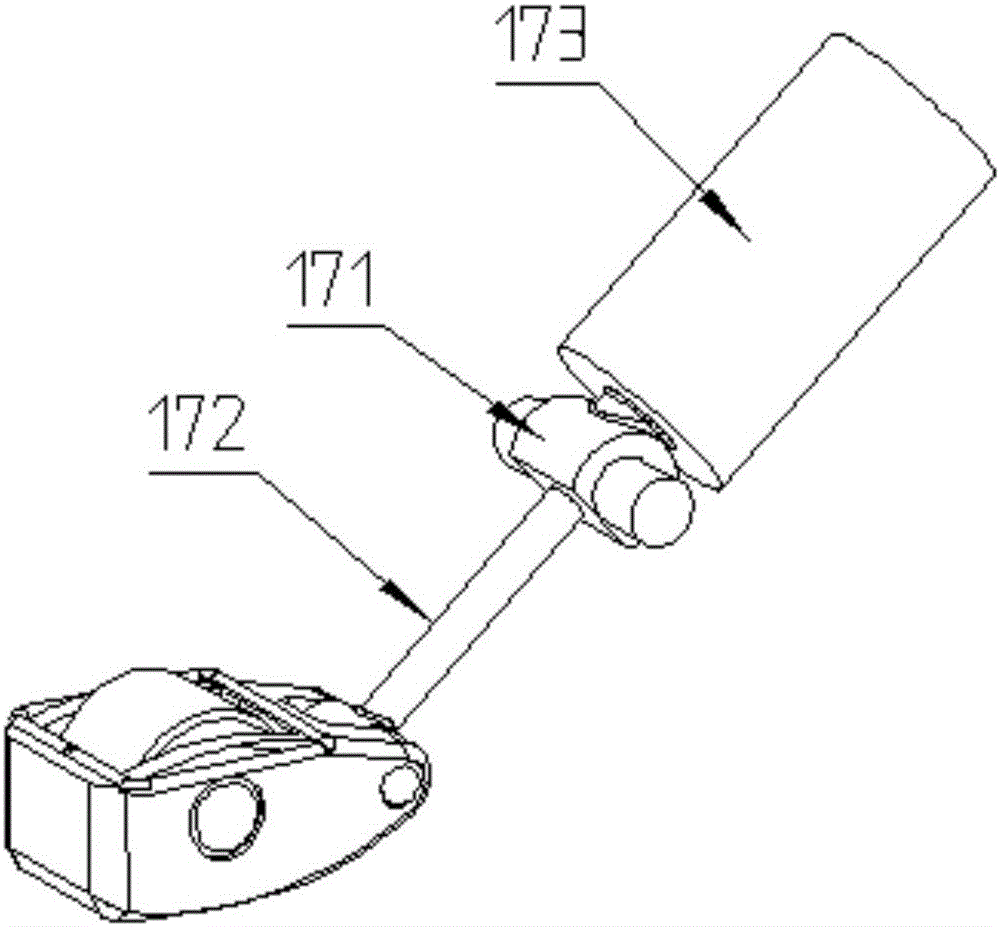

[0039] Such as figure 1 , Figure 7 , Figure 8 As shown, the present invention provides a continuously variable rocker arm valve mechanism, which includes a rocker arm 110 , the bottom surface of the left end of which is in contact with the valve 120 , and the right end is supported by a hydraulic tappet 130 . When the rocker arm 110 is subjected to a downward force, the bottom surface of the left end can push the valve 120 to open.

[0040] The cam 140 is fixed on the camshaft 150, and the camshaft 150 is supported on the cylinder head. When the camshaft 150 rotates, it can drive the cam 140 to rotate together.

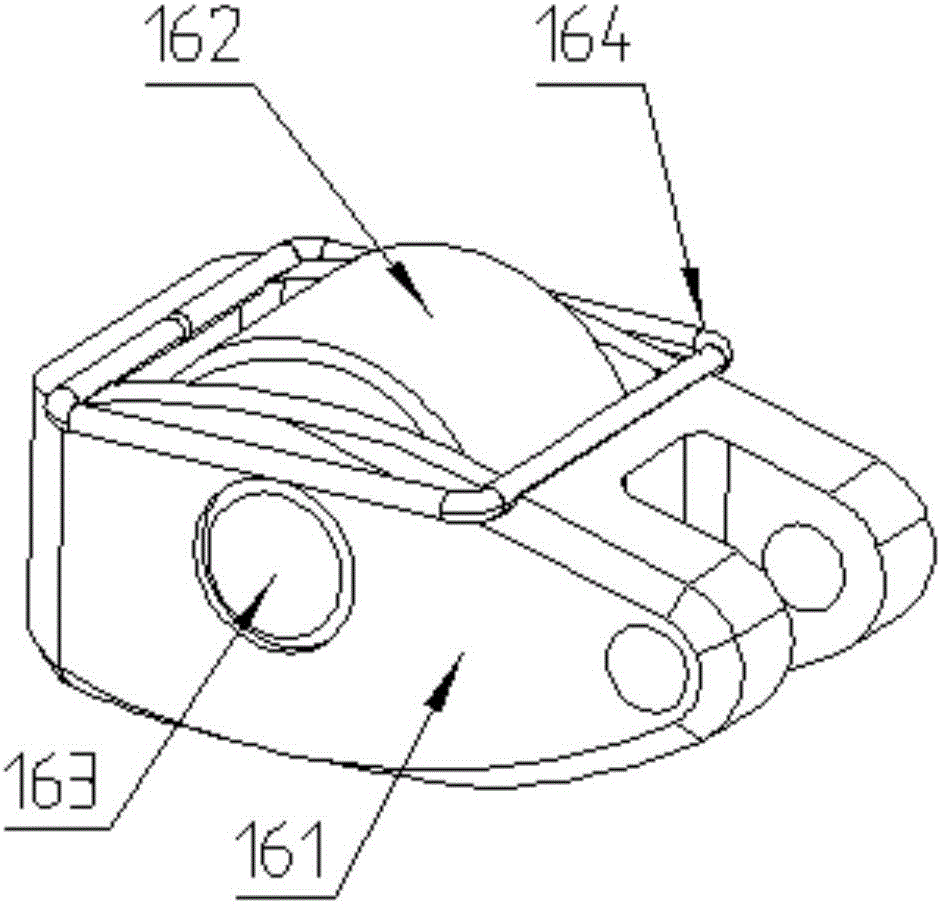

[0041] The rocker arm 110 is provided with a cavity, and the slider assembly 160 is disposed in the cavity. Two arc slide grooves 111 are arranged on the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com