Integrated tail gas aftertreatment system

A tail gas post-treatment and tail gas technology, which is applied in exhaust gas treatment, gas channels, exhaust devices, etc., to achieve the effect of improved mixing uniformity and efficient and low elimination of harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present application generally relates to an exhaust aftertreatment system for treating engine exhaust, the exhaust aftertreatment system being installed in the engine compartment. The exhaust aftertreatment system of the present application is typically suitable for treating the exhaust of diesel engines; however, the exhaust aftertreatment system is also applicable to other types of engines (some components in the system may need to be modified accordingly).

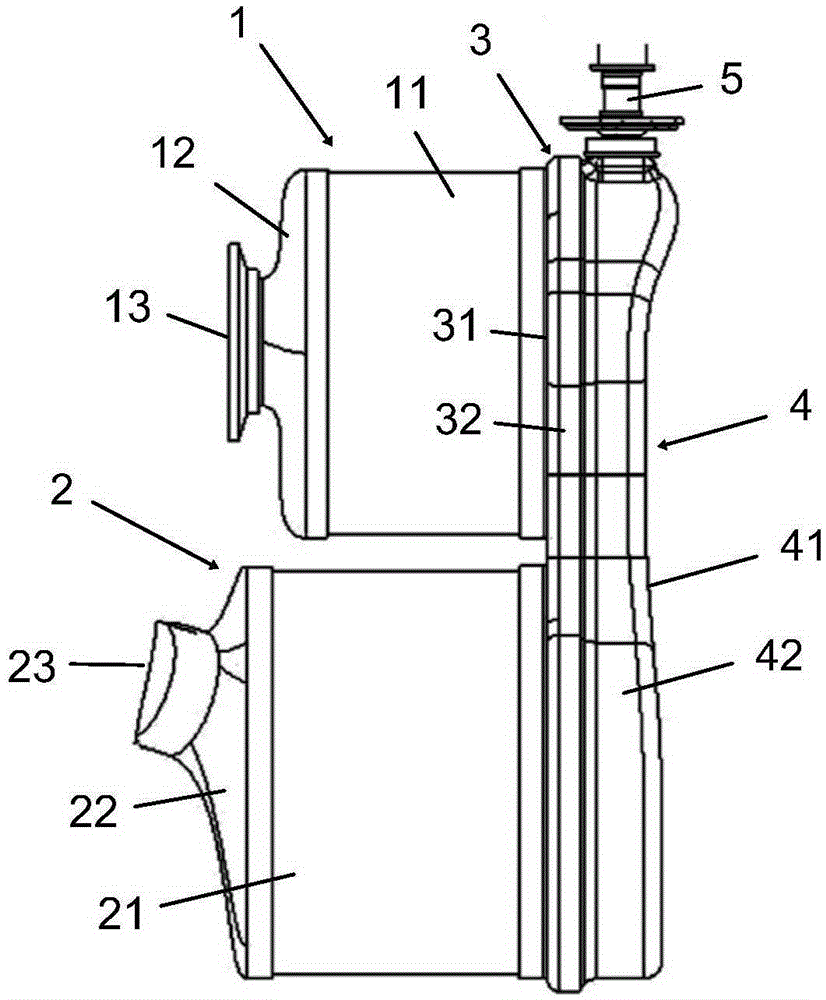

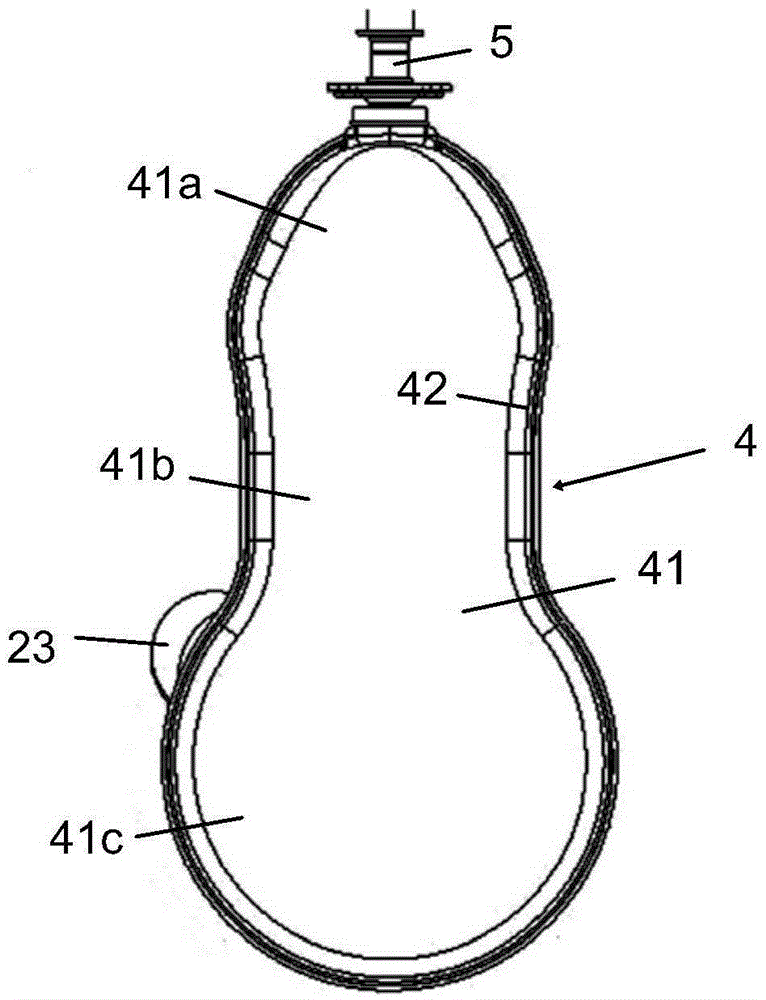

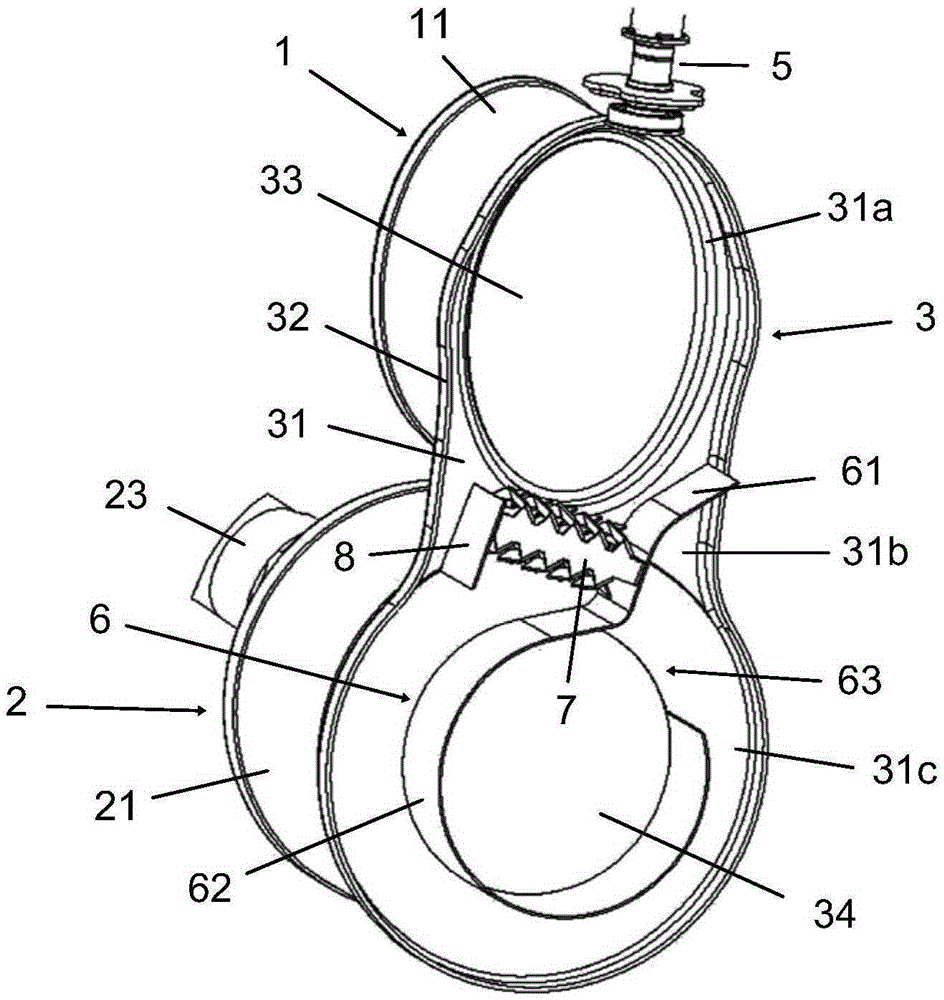

[0038] Figures 1 to 3 The integrated exhaust gas aftertreatment system of the present application is shown. The exhaust gas aftertreatment system mainly includes an oxidation catalyst unit 1 and a SCRoF unit 2 . The SCRoF unit 2 is a one-piece assembly in which the selective catalytic reduction function and the particle trapping (filtration) function are combined. The oxidation catalyst unit 1 and the SCRoF unit 2 are assembled in a first cover 3 , and the first cover 3 and the second cover 4 constitute a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com