Cam shaft type combustion chamber variable-capacity piston internal combustion engine

A technology for internal combustion engines and combustion chambers, applied in engine components, engine control, machines/engines, etc., can solve the problems of high fuel consumption, high ignition power consumption, etc., and achieve the effects of reducing fuel consumption, improving fuel efficiency, and reducing internal friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

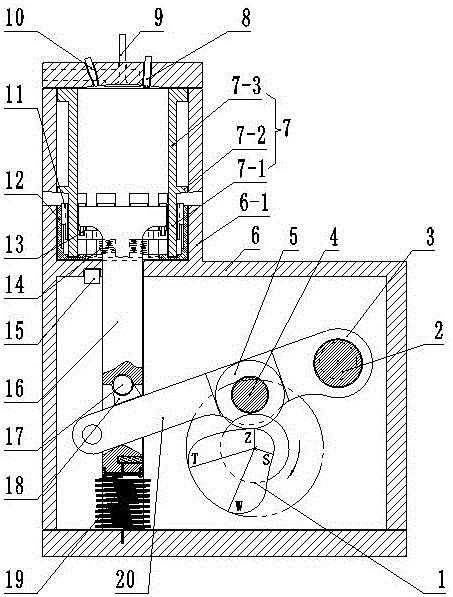

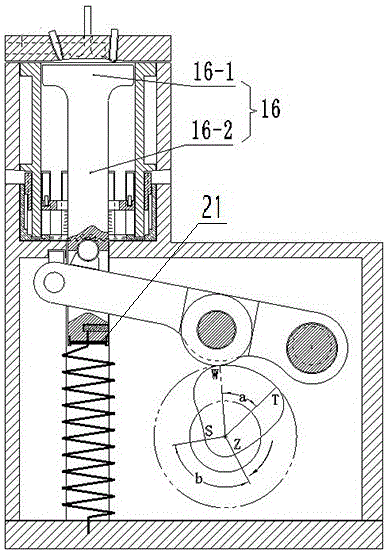

[0021] like figure 1 , figure 2 and image 3 The shown camshaft type combustion chamber variable displacement piston internal combustion engine includes a cylinder 7 and a piston 16 installed in the cylinder 7, a cylinder head is provided on the cylinder 7, and a fuel injector 10 and an intake valve 9 are provided on the cylinder head. And the spark plug 8; the cylinder 7 has a working section 7-3 and a fence exhaust section 7-1 with a plurality of notches distributed at the outer edge, and the openings of the plurality of notches face downwards. There is a limiting convex ring 7-2 at the connection of the fence exhaust part 7-1; the fence exhaust part of the cylinder 7 is inserted into the fence hole 11-2 distributed in the fence type exhaust valve 11, as shown in Figure 4 and Figure 5 shown; the fence type exhaust valve 11 slides on a plurality of annular vertical slideways of the exhaust valve sleeve 12 through the slider 11-1 on its outer edge, and the fence type exh...

Embodiment 2

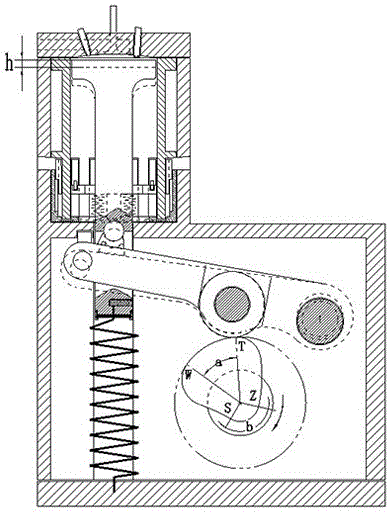

[0023] The central angle a of the equal diameter flange area TW at the top dead center of the power cam 1 is 55°, and the central angle b of the equal diameter flange area SZ at the bottom dead center of the power cam 1 is 110°.

Embodiment 3

[0025] The central angle a of the equal diameter flange area TW at the top dead center of the power cam 1 is 50°, and the central angle b of the equal diameter flange area SZ at the bottom dead center of the power cam 1 is 108°.

[0026] During operation, the mixed gas in the combustion chamber is ignited and an expansion force is generated to push the piston body 16-1, and the rod portion 16-2 of the piston 16 drives the rocker arm 3, and the rocker arm 3 rotates by pressing the power cam 1 downward, and the piston body works externally. When 16-1 runs to the vicinity of the bottom dead center, the piston body 16-1 continues to move downward under the combined action of inertia and return spring 19, and the piston body 16-1 drives the fence type exhaust valve 11 to move downward at the same time, and the cylinder The gas in 7 is discharged to the outside; the piston body 16-1 runs to the bottom dead center (the S point of the power cam), because at this time, the thrust pulley...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com