Diesel engine air inlet adapter pipe device

A technology for diesel engines and air intake pipes, which is applied in the direction of engine components, machines/engines, and charging systems. It can solve the problems of limited space and increased external volume of the engine body, and achieve the effect of ample space and effective control of external dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

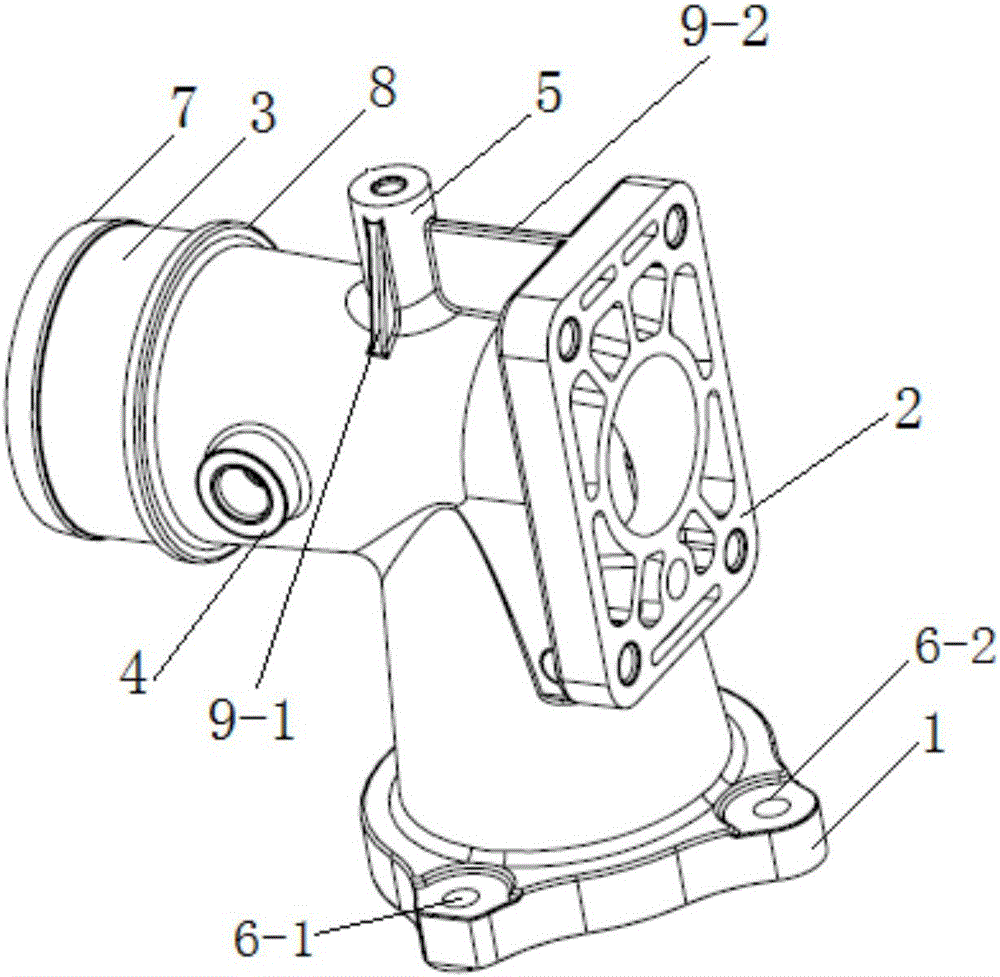

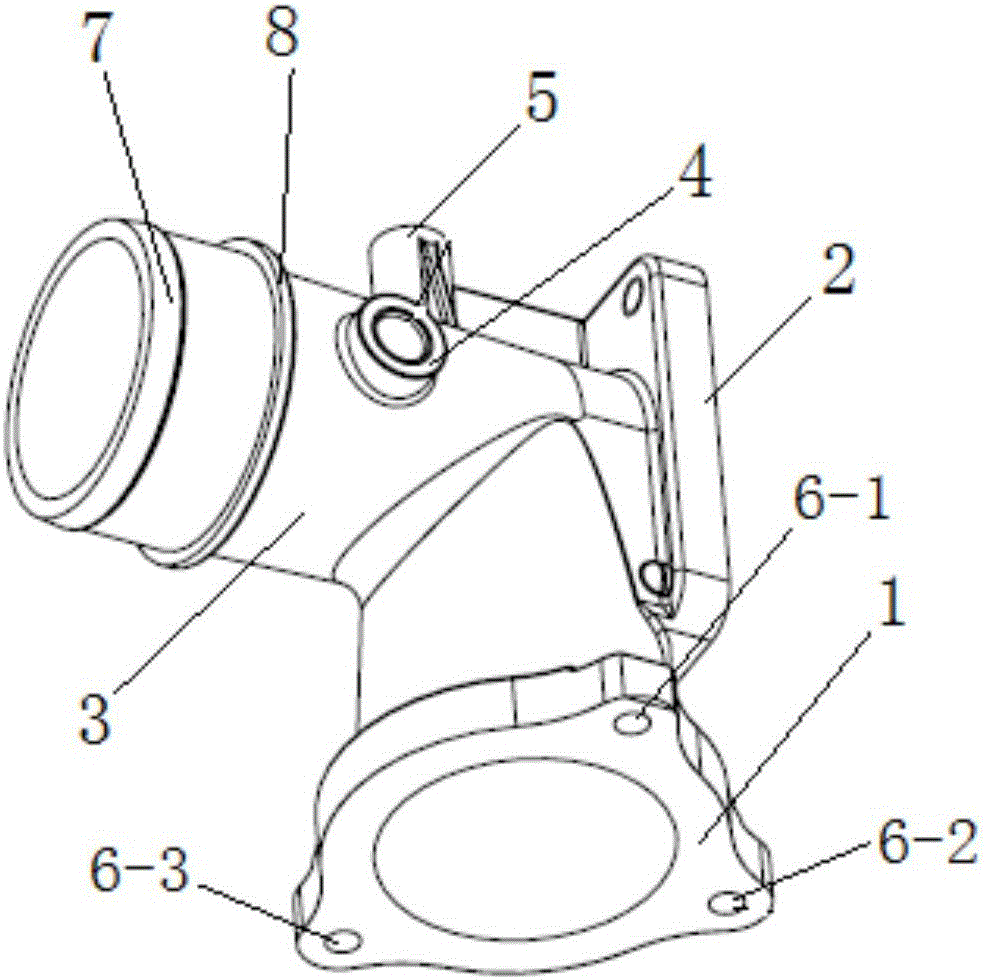

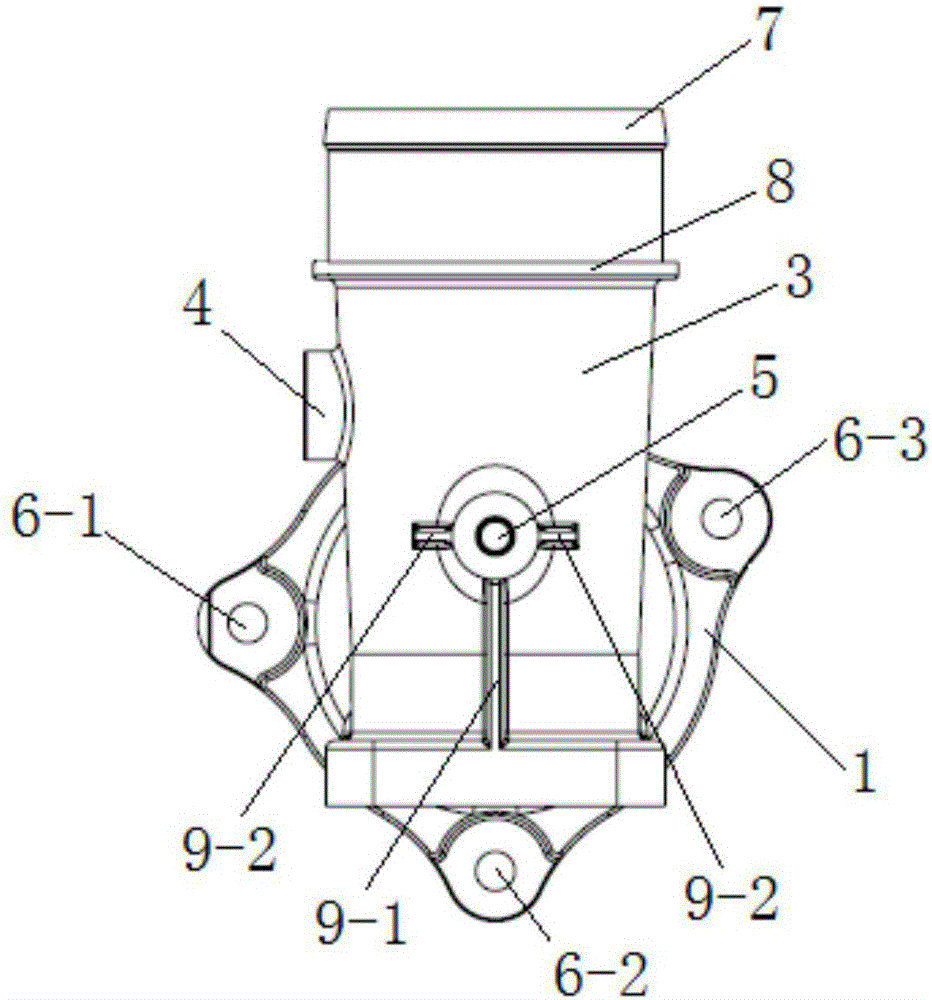

[0009] The principle and structure of the present invention will be described in detail below in conjunction with the accompanying drawings and through embodiments.

[0010] The diesel engine air intake connection device has the following structure: the intake pipe installation surface 1 is perpendicular to the EGR valve installation surface 2 and the exhaust connection pipe 3, and the three channels communicate with each other. A horizontal navel 4 and a vertical navel 5 are cast on the exhaust pipe, and the centers of the two navels are provided with processing holes. The horizontal navel is used to install the intake air temperature sensor and pressure sensor; the vertical navel is used to install the EGR. Bracket for control valve harness and pressure sensor harness.

[0011] The installation surface of the intake pipe is provided with three equal-thickness bosses distributed asymmetrically, and the centers of the three bosses are all processed with through holes 6-1 to 6-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com