Intelligent hot water supply equipment based on air compressor afterheat recovery

A waste heat recovery and air compressor technology, applied in mechanical equipment, lighting and heating equipment, space heating and ventilation, etc., can solve problems such as inability to wash, poor waste heat recovery, and waste of air compressors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

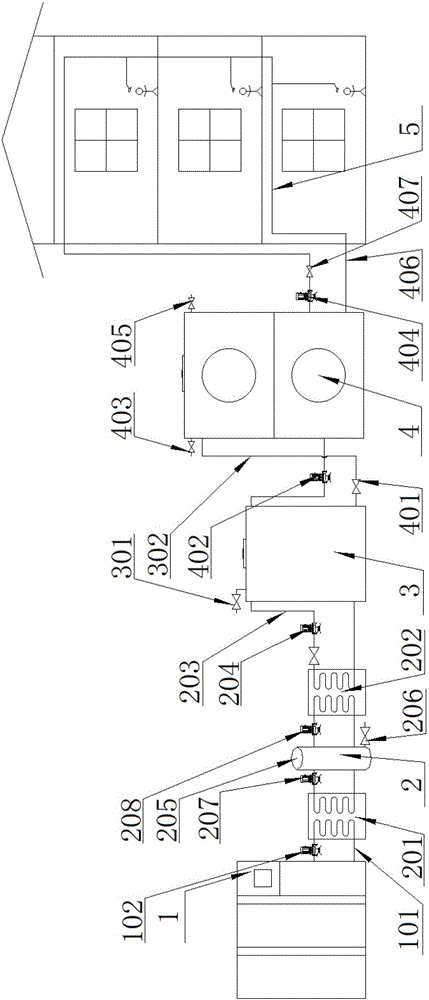

[0016] Such as figure 1 As mentioned above, it is an intelligent hot water supply equipment based on waste heat recovery from an air compressor, including an air compressor 1 and a control cabinet for controlling the entire equipment. The air compressor 1 is connected to a heat exchange tank 3 via a heat exchange plate 2 In order to improve the heat exchange efficiency and facilitate the regulation of water temperature, the heat exchange plate 2 includes a primary heat exchange plate 201 connected to the circulating oil circuit 101 of the air compressor 1, the primary heat exchange plate 201 is connected to a water storage tank 205, and The water tank 205 is connected with a secondary heat exchange plate 202, and the secondary heat exchange plate 202 is connected to the first circulating water pipe 203. The water storage tank 205 is provided with a third replenishment valve 206 connected to the peripheral cold water. The air compressor A circulating oil pump 102 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com