Rotary compressor using R600a or R600 as main refrigerant and application

A technology of rotary compressor and refrigerant, which is applied in the direction of rotary piston machinery, rotary piston pump, pump combination for elastic fluid rotary piston type/oscillating piston type, etc., which can solve the problem of reducing mechanical efficiency and reducing compressor Volumetric efficiency, reduce mechanical efficiency and other issues, to achieve the effect of reducing viscous resistance loss, ensuring the level of mechanical efficiency, and optimizing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

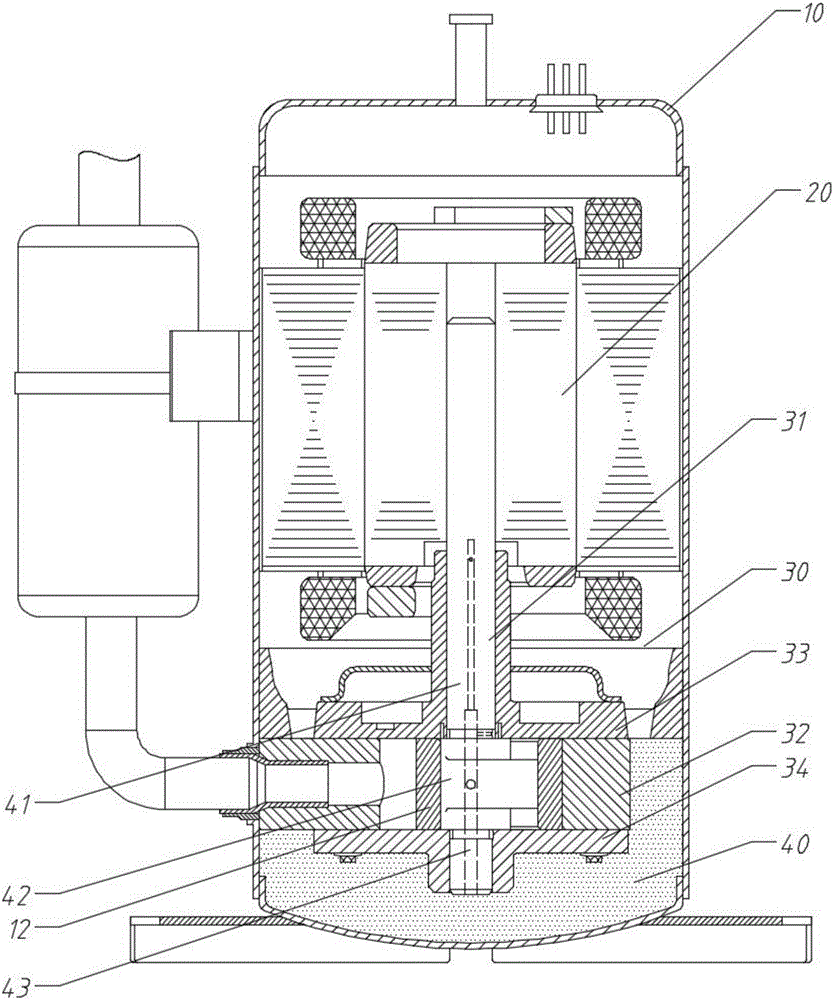

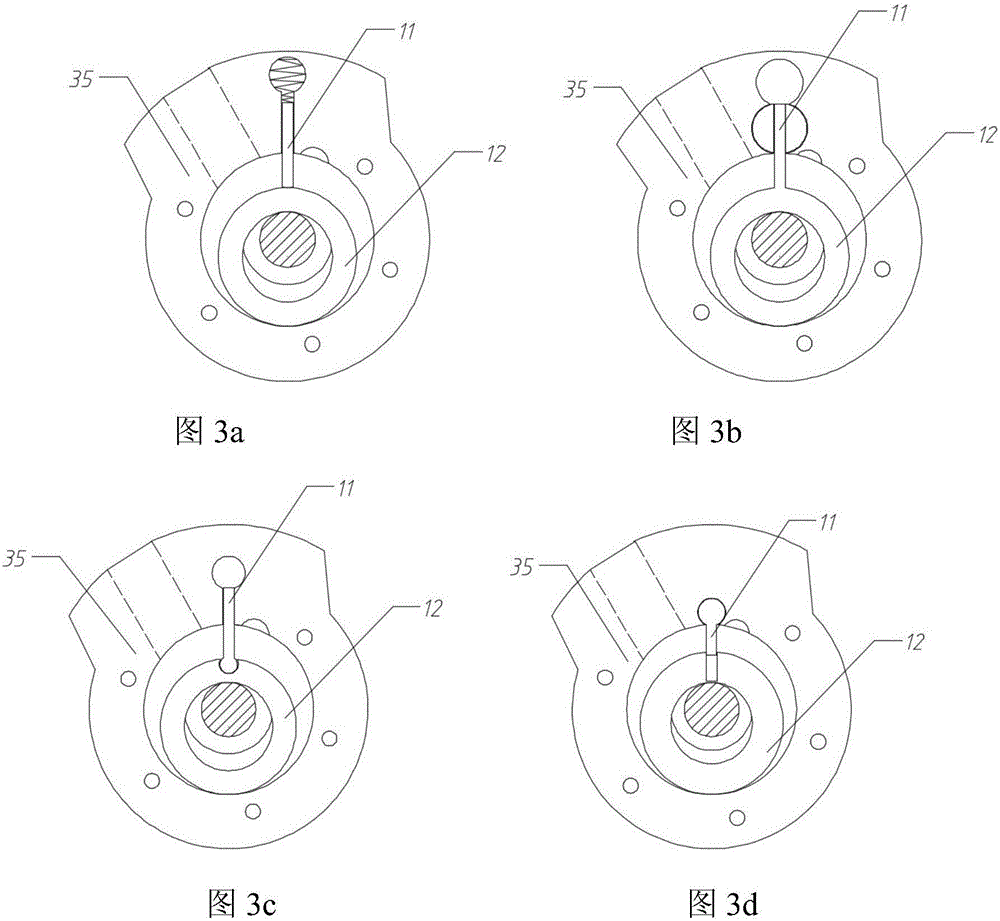

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

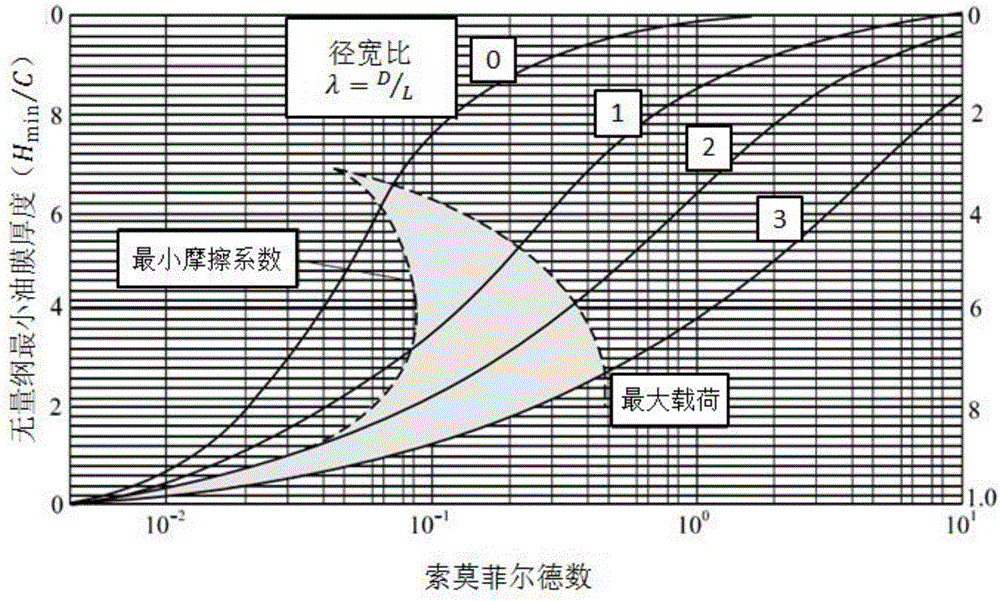

[0034] The invention obtains various working conditions of the rotary compressor by performing thermodynamic calculation on refrigeration cycle systems such as refrigerators and freezers. Then, according to the obtained working conditions and the basic structure of the rotary compressor, the finite element method is used to analyze the pressure distribution of each position inside it, so as to obtain the load P of each friction pair b . Then combined with the dimensionless minimum oil film thickness Graph vs. Sommerfeld number S through minimum oil film thickness H min Analyze the applicable lubricating oil viscosity range.

[0035] First, the minimum oil film thickness H is determined by ensuring the ratio of the minimum oil film thickness to the roughness of the two friction surfaces Λ≥3 min . Then through the dimensionless mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com