Opposite-direction pressure relief equipment

A device and pressure release technology, applied in mechanical equipment, springs, shock absorbers, etc., can solve the problems of short stroke, insufficient energy absorption performance and limited energy, and achieve the effect of improving energy absorption capacity and increasing stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

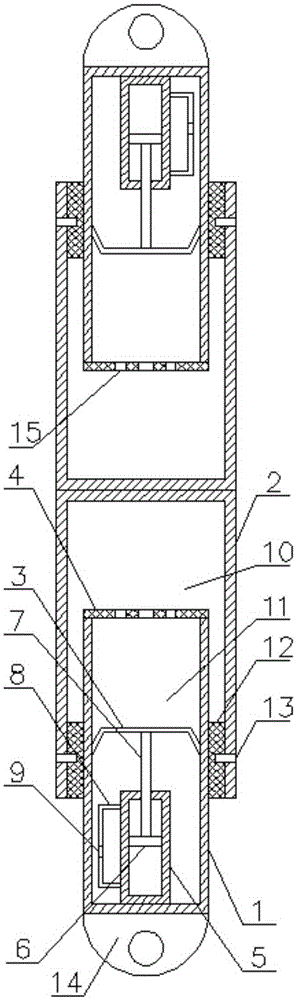

[0028] Such as figure 1 As shown, the opposing pressure relief equipment includes two interconnected pressure relief devices, the pressure relief device includes an inner cylinder 1, an outer cylinder 2, a floating piston 3, a damping body 4, a pressure storage cylinder 5, a piston 6, and a piston Rod 7, connecting pipe 8 and damping block 9; the upper end of the outer cylinder 2 is closed, the lower end of the outer cylinder 2 is open, the upper end of the inner cylinder 1 is open, and the lower end of the inner cylinder 1 is closed; the damping body 4 is arranged on the upper end of the inner cylinder 1 , the damping body 4 is provided with a damping hole; the floating piston 3 is set in the inner cylinder 1, the piston 6 is set in the pressure storage cylinder 5, the piston rod 7 runs through the top of the pressure storage cylinder 5 and is connected to the piston 6, and the pressure storage cylinder 5 Set in the inner cylinder 1 and connected to the bottom of the inner cy...

Embodiment 2

[0035] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and a sealing support member 12 is provided between the bottom inner surface of the outer cylinder 2 and the outer surface of the inner cylinder 1 .

[0036] A sealing support member 12 is provided to avoid oil leakage in the outer cylinder.

Embodiment 3

[0038] Such as figure 1 As shown, this embodiment is based on Embodiment 2, and the sealing support member 12 is connected to the outer cylinder 2 through a pin shaft 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com