A metal hose connection structure

A technology of metal hose and connection structure, which is applied in the direction of hose connection device, sealing surface connection, pipe/pipe joint/pipe fitting, etc. The hose body is broken and leaked, so as to avoid the failure to fix tightly, reduce the risk of rupture and leakage, and improve the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

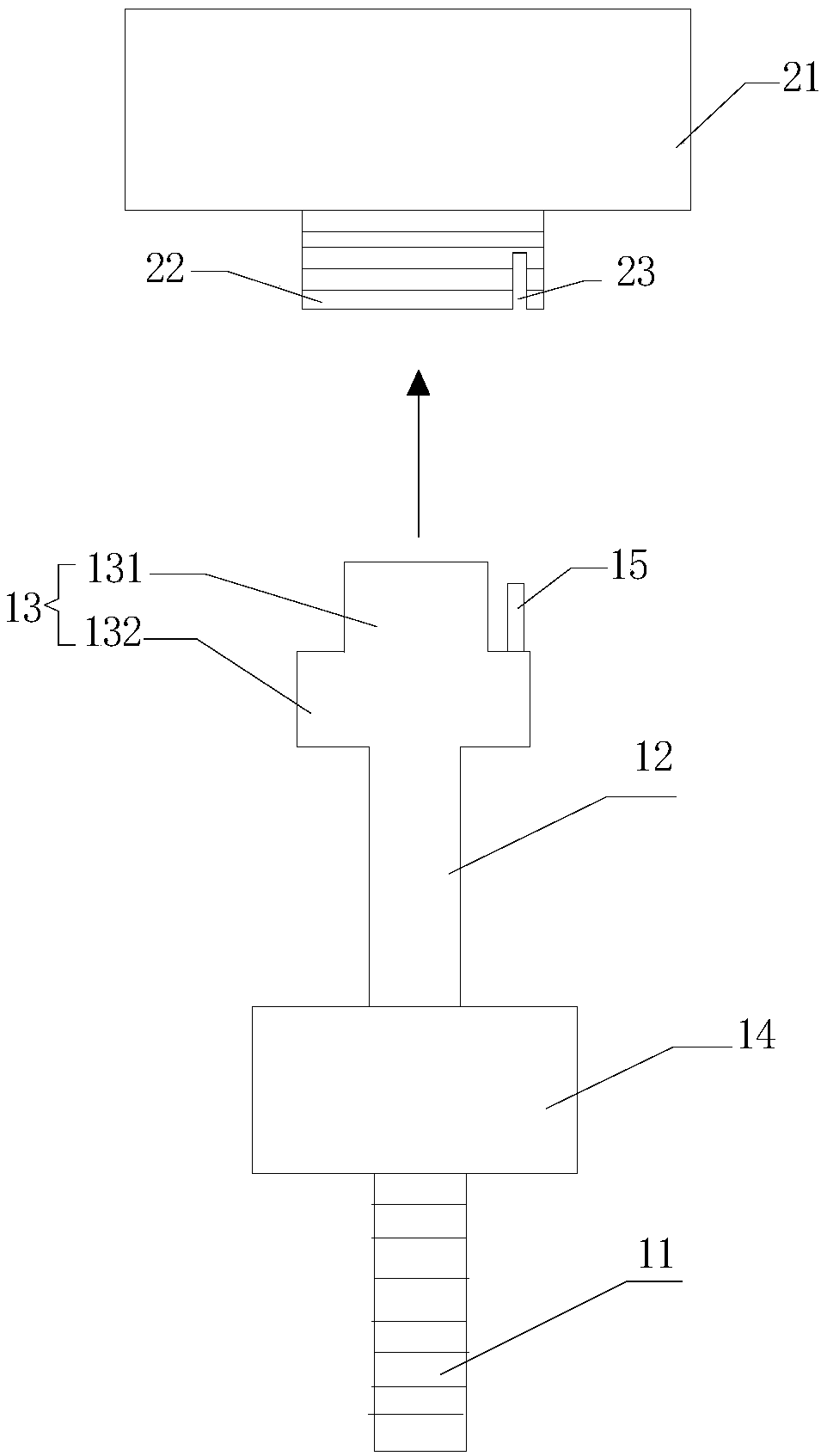

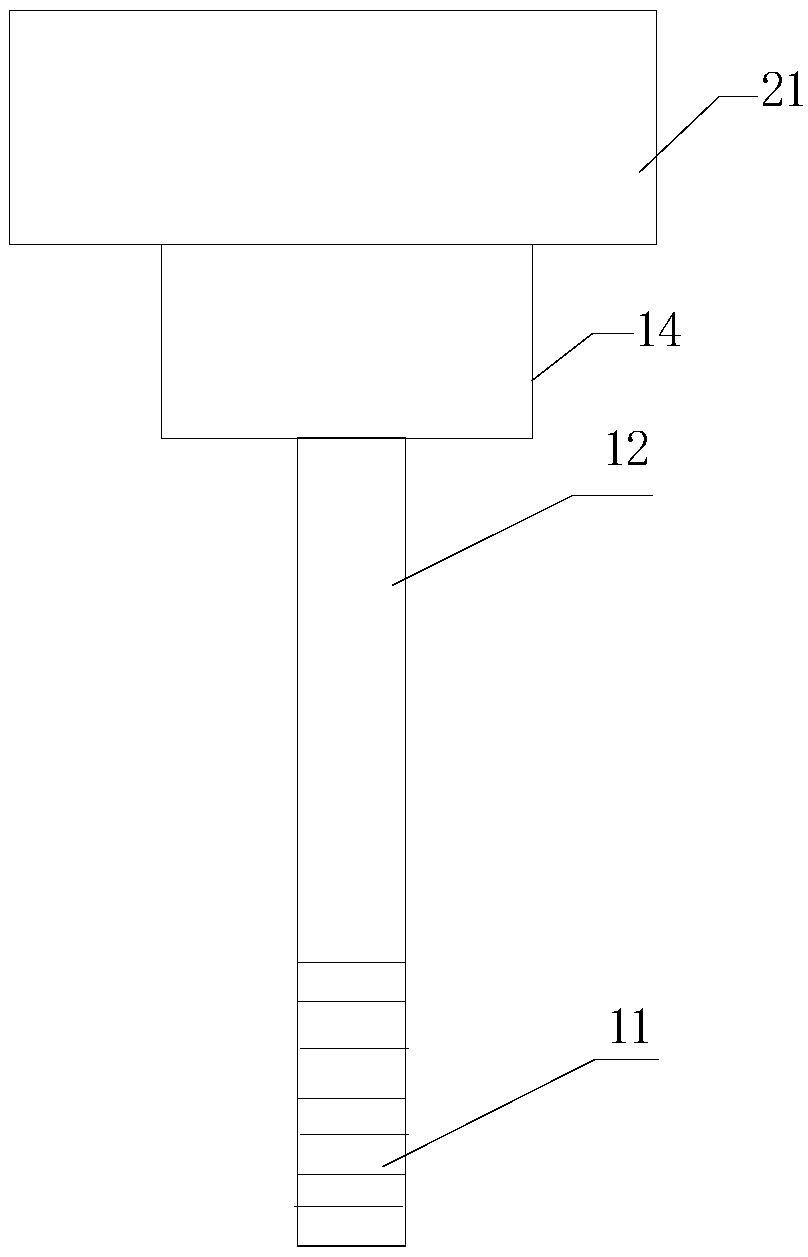

[0034] like Figure 1a and Figure 1b As shown, this embodiment relates to a metal hose connection structure, which can be applied to fix the metal hose body 11 on the inlet and outlet manifolds 21, and fix the hose connector 13 by setting the positioning pin 15 to eliminate the hose connector 13 Frictional movement due to the tightening nut 14 by rotation.

[0035] Specifically, the above-mentioned metal hose connection structure includes a manifold joint 22 and a metal straight pipe 12, the manifold joint 22 is arranged on the inlet and outlet manifold 21; one end of the metal straight pipe 12 is connected to the metal hose body 11, and the other end is provided with a The hose joint 13 that is compatible with the manifold joint 22 (the hose joint 13 is adapted to the manifold joint 22 is specifically: the upper part 131 of the hose joint 13 (that is, the part where the flange is not provided in the figure, the upper part and the lower part can be Referring to the position ...

Embodiment 2

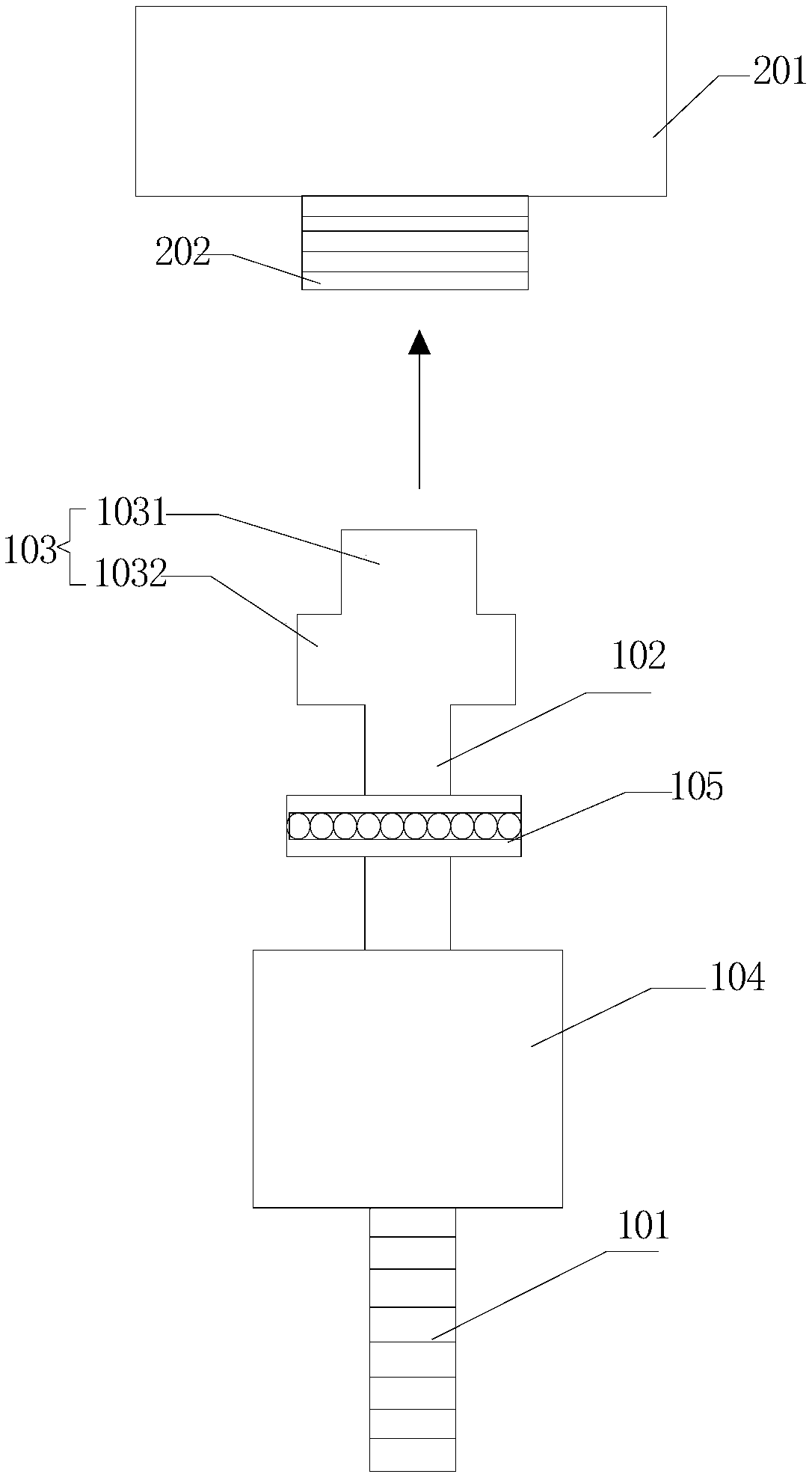

[0041] like Figure 2a and Figure 2b As shown, this embodiment relates to a metal hose connection structure, which can be applied to fix the metal hose body 101 on the inlet and outlet manifold 201 , and the frictional rotation can be minimized by setting the plane bearing 105 .

[0042] Specifically, the above-mentioned metal hose connection structure includes a manifold joint 202 and a metal straight pipe 102. The manifold joint 202 is arranged on the inlet and outlet manifold 201; one end of the metal straight pipe 102 is connected to the metal hose body 101, and the other end is provided with a The hose joint 103 that the manifold joint 202 is compatible with (the hose joint 103 is adapted to the manifold joint 202 is specifically: the outer diameter of the upper part 1031 of the hose joint 103 (that is, the part that is not provided with a flange) is approximately Smaller than the inner diameter of the manifold joint 202, and the length of the upper part 1031 of the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com