Fiber optic F-P sound pressure sensor based on metal film

A sound pressure sensor, metal pattern technology, applied in the coupling of instruments, optical waveguides, measuring ultrasonic/sonic/infrasonic waves, etc. Improve detection accuracy, improve deformation, and reduce the effect of production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

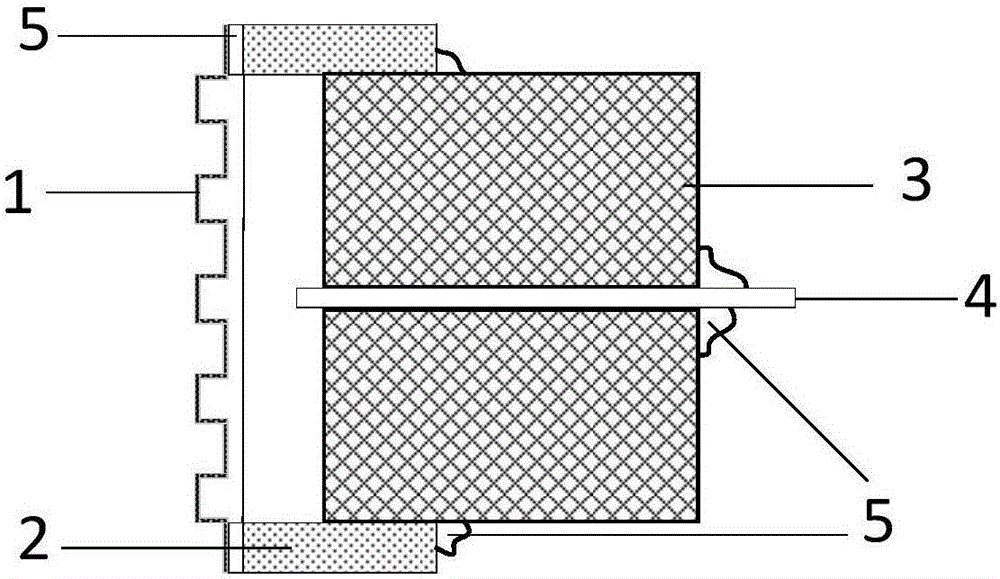

[0042] The optical fiber F-P sound pressure sensor based on the metal pattern film of the present embodiment, the structure schematic diagram is as follows figure 1 shown. The optical fiber F-P sound pressure sensor based on the metal pattern film includes a metal corrugated film 1, a through-cavity sleeve 2, a ferrule 3 and an optical fiber 4; One end face of the lumen sleeve 2 is inserted with a ferrule 3 matching the inner wall of the lumen sleeve 2 from the other end face of the lumen sleeve 2, and an optical fiber 4 with a polished end face is inserted in the center of the ferrule 3; the through lumen sleeve 2. The ferrule 3 and the optical fiber 4 are coaxially arranged, the sleeve 2 and the ferrule 3 are fixed with curing glue 5, and the ferrule 3 and the optical fiber 4 are fixed with curing glue 5; the metal corrugated film 1 and the end surface of the optical fiber 4 are fixed The metal corrugated film 1 vibrates under the action of external sound pressure, which ca...

specific Embodiment 2

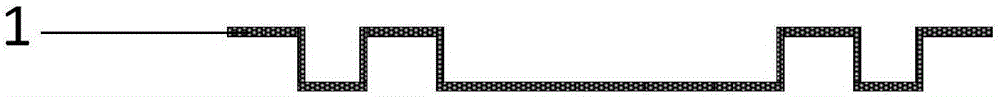

[0044] The metal corrugated film-based optical fiber F-P sound pressure sensor of this embodiment further defines the structure of the metal corrugated film 1 on the basis of the first embodiment. The metal corrugated film 1 is flat in the middle and has a wrinkled structure on the edge; the diameter of the flat middle part is larger than the diameter of the optical fiber 6, and the flat part in the middle is an F-P cavity to the end face of the optical fiber 6; the cross-sectional shape of the wrinkled corrugation is Periodic sinusoidal, rectangular, triangular, or trapezoidal.

[0045] In this embodiment, the cross-sectional shape of the corrugated corrugations is a periodic rectangle, such as figure 2 shown.

specific Embodiment 3

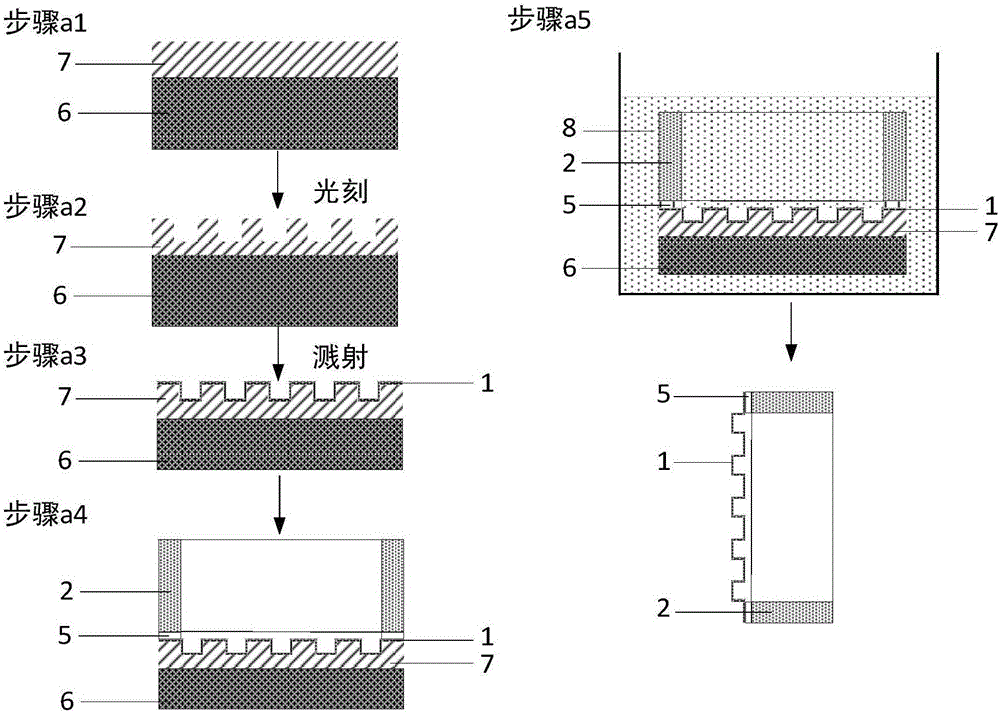

[0047] The optical fiber F-P sound pressure sensor based on the metal pattern film of the present embodiment, on the basis of the specific embodiment 1, further defines its processing method, including the following steps:

[0048] Step a, making metal corrugated film 1;

[0049] Step b, attaching the metal corrugated film 1 to one end surface of the through-cavity sleeve 2 with curing glue 5;

[0050] Step c, insert the ferrule 3 that matches the inner wall of the through-cavity sleeve 2 from the other end face of the through-cavity sleeve 2, and fix it with curing glue 5;

[0051] Step d. Insert the optical fiber 4 whose end surface is polished and smooth from the center of the ferrule 3 , adjust the length of the optical fiber 4 , and fix it with curing glue 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com