Durability testbed of flywheel for automobile and test method thereof

A technology of durability test and test platform, which is applied in the test of machine gear/transmission mechanism, the test of mechanical components, the test of machine/structural components, etc. It can solve the problems of inability to achieve high-frequency and high-precision control, and achieve novel experimental methods. , easy to operate, strong controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

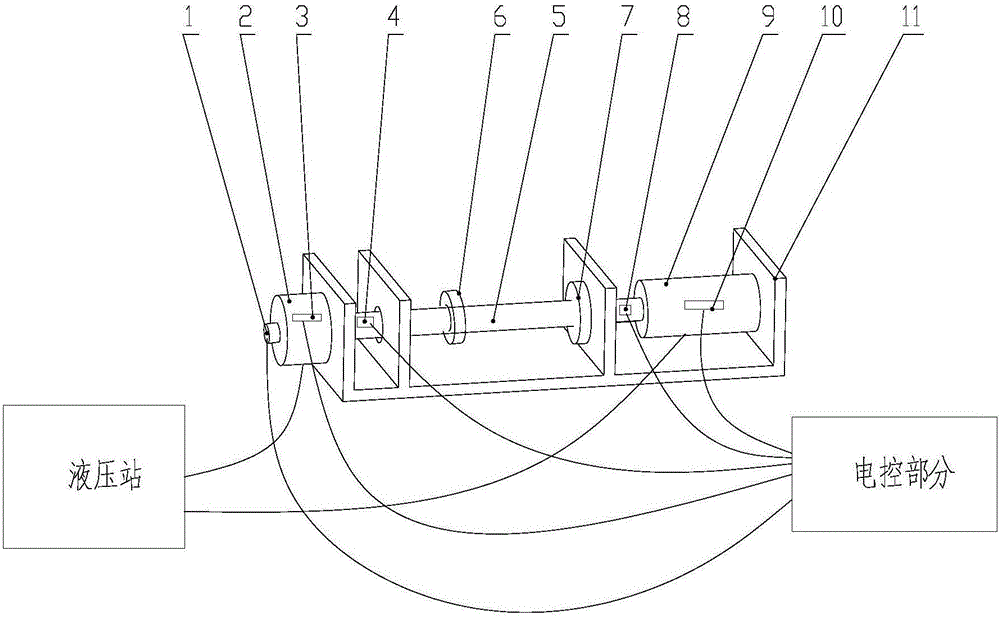

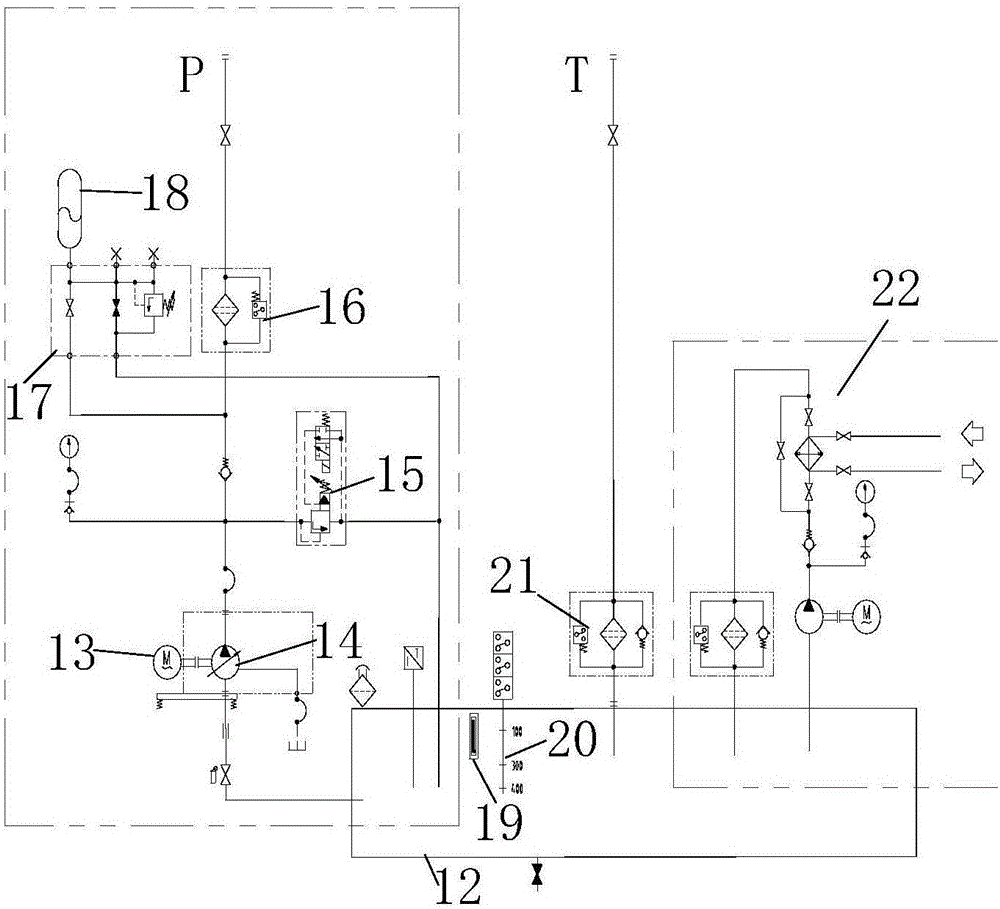

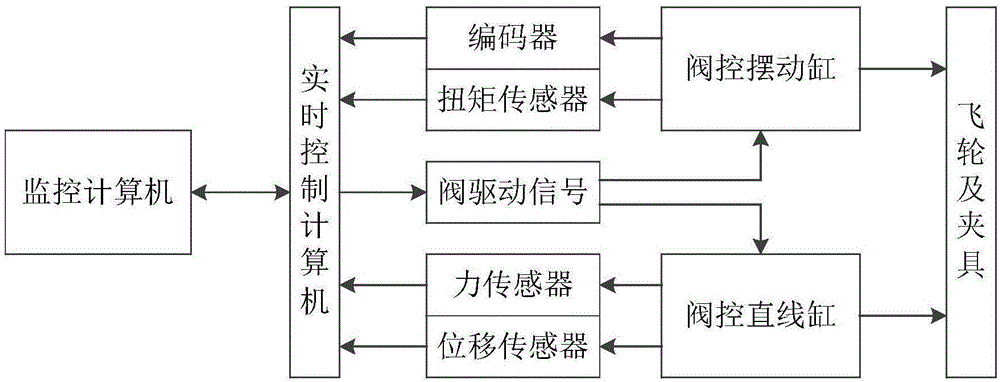

[0029] figure 1 Shown is an embodiment of the automobile flywheel durability test bench of the present invention, and the automobile flywheel durability test bench includes a mechanical structure, a hydraulic station and an electric control part. Among them, the hydraulic station provides the power source for the system, the mechanical structure provides the installation of the automobile flywheel fixture, and the electronic control part provides real-time control of the swing hydraulic cylinder 2 and the servo hydraulic cylinder 9.

[0030] The mechanical structure includes a test platform 11, a swing hydraulic cylinder 2, a first servo valve 3, a transmission shaft 5, a connecting part 6, an automobile flywheel 7, a servo hydraulic cylinder 9 and a second servo valve 10; The base is fixedly installed on the left end of the test platform 11, and the drive shaft of the swing hydraulic cylinder 2 passes through the first baffle plate and the second baffle plate on the left side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com