Preparation method of paraffin section of cannabis sativa callus

A technology of callus and paraffin sectioning, which is applied in the preparation of test samples, etc., can solve the problems of low efficiency, time-consuming and labor-consuming paraffin sectioning technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

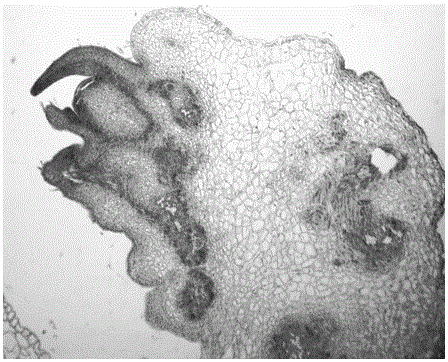

Image

Examples

Embodiment 1

[0039] The preparation method of the paraffin section of the hemp callus of the present embodiment may further comprise the steps:

[0040] 1. Material collection and fixation:

[0041] (1) Select the marijuana callus material after culturing for 5 days, wash it with running water, and remove the medium and other sundries;

[0042] (2) absorb the moisture on the surface of the hemp callus with filter paper;

[0043] The cannabis callus material was immersed in the improved FAA fixative solution and fixed for 24 hours; in order to make the fixative solution penetrate into the cannabis callus tissue better, the fixed material was placed in an aspirating device and pumped for 1 hour;

[0044] Because of the tenderness of the hemp callus material, in order to prevent the material from shrinking, the FAA fixative has been improved. The improved FAA fixative of the present invention is: formaldehyde solution (formalin) with a mass concentration of 38%, glacial acetic acid and The ...

Embodiment 2

[0068] The preparation method of the paraffin section of the hemp callus of the present embodiment may further comprise the steps:

[0069] 1. Material collection and fixation:

[0070] (1) Select the marijuana callus material after culturing for 9 days, wash it with running water, and remove the medium and other sundries;

[0071] (2) absorb the moisture on the surface of the hemp callus with filter paper;

[0072] The cannabis callus material was immersed in the improved FAA fixative solution and fixed for 24 hours; in order to make the fixative solution penetrate into the cannabis callus tissue better, the fixed material was placed in an aspirating device and pumped for 1 hour;

[0073] Because the hemp callus material is young and tender, in order to prevent the material from shrinking, the FAA fixative has been improved. The improved FAA fixative of the present invention is: formaldehyde solution (formalin) with a mass concentration of 40%, glacial acetic acid and The e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com