Preparation method of super activated carbon and method for recycling waste liquid and producing carbonate by-product

A technology of activated carbon and carbonate, applied in the direction of alkali metal carbonate, chemical instruments and methods, carbon compounds, etc., can solve the problems of high concentration, waste of materials, high labor costs, etc., to improve yield and specific surface area, The effect of reducing production cost and improving activation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] On the one hand, the invention provides a kind of preparation method of super activated carbon, wherein, the method comprises:

[0069] (1) Under vacuum conditions, contacting the carbonaceous material with an oxidizing agent and a hydrating alkaline activator, so that the oxidizing agent and the hydrating alkaline activating agent are immersed in the carbonaceous material;

[0070] (2) performing a first heat treatment on the carbonaceous material immersed in an oxidizing agent and a hydrated alkaline activator to activate the carbonaceous material and obtain carbon dioxide gas;

[0071](3) cooling, washing and drying the activated carbonaceous material obtained in step (2) to obtain super activated carbon products and carbon dioxide gas.

[0072] The inventors of the present invention found in their research that by immersing oxidants and hydrated alkaline substances into the interior of the carbonaceous material to be activated under vacuum conditions, the yield and ...

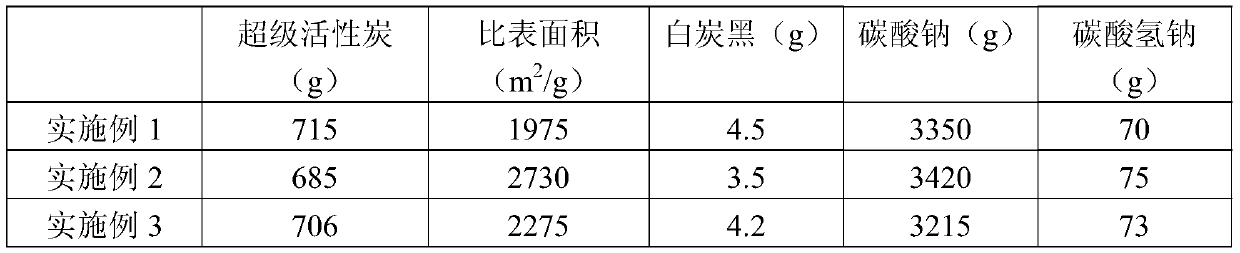

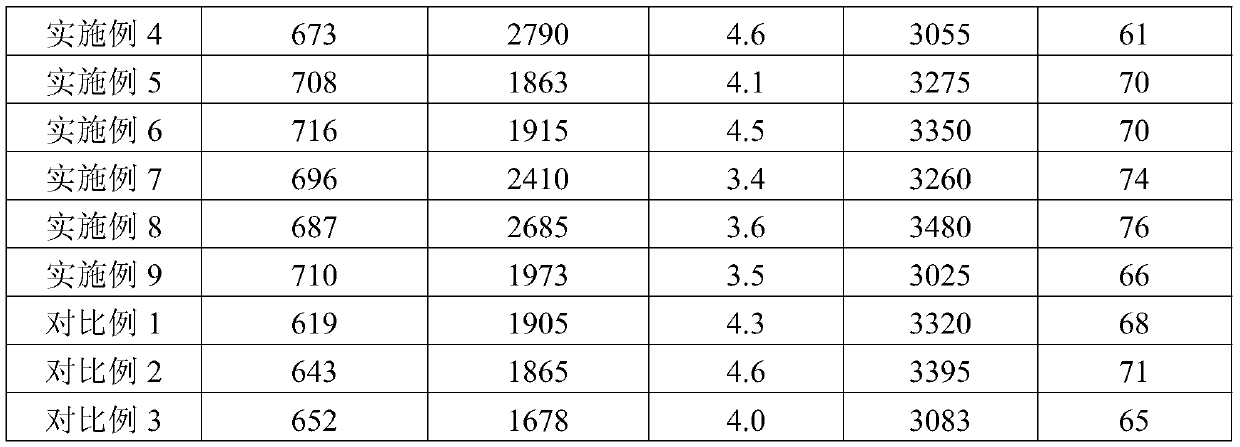

Embodiment 1

[0118] This embodiment is used to illustrate the preparation method of the super activated carbon provided by the present invention and the recycling of the produced waste liquid and the method of by-product sodium carbonate.

[0119] 1. Preparation process of super activated carbon

[0120] (1) 1 kg of apricot shell charcoal is crushed to 40-60 mesh, followed by pre-cleaning, and the water content of the apricot shell charcoal is 20% by weight. Then heat treatment A process was carried out at 600° C. for 50 minutes to obtain preactivated activated carbon. After cooling, immerse 90 grams of sodium peroxide aqueous solution with a concentration of 3% in a vacuum reaction kettle with a vacuum degree of -0.015 MPa for 5 minutes.

[0121] (2) Reheat the pre-activated activated carbon immersed in sodium peroxide to 640°C and keep it for 20 minutes to obtain the first activated activated carbon. Cool the first activated activated carbon to 120°C, and the vacuum degree is -0.06MPa ...

Embodiment 2

[0139]This embodiment is used to illustrate the preparation method of the super activated carbon provided by the present invention and the recycling of the produced waste liquid and the method of by-product sodium carbonate.

[0140] 1. Preparation process of super activated carbon

[0141] (1) 1kg of coconut shell charcoal is crushed to 40-80 mesh, followed by pre-cleaning, and the water content of the almond shell charcoal is 30% by weight. Then heat treatment A process was carried out at 350° C. for 60 minutes to obtain preactivated activated carbon. After cooling, immerse 50 grams of hydrogen peroxide aqueous solution with a concentration of 1% in a vacuum reaction kettle with a vacuum degree of -0.01 MPa for 10 minutes.

[0142] (2) Reheat the pre-activated activated carbon immersed in hydrogen peroxide to 700°C and keep it for 5 minutes to obtain the first activated activated carbon. Cool the first activated activated carbon to 95°C, and the vacuum degree is -0.08MPa I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com