High-speed railway ballastless track subgrade rising soil test system and test method thereof

A technology for mud-flushing and ballastless track, which is applied in the field of mud-flushing test system for ballastless track subgrade of high-speed railways, and can solve problems such as difficulty in effectively adopting the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

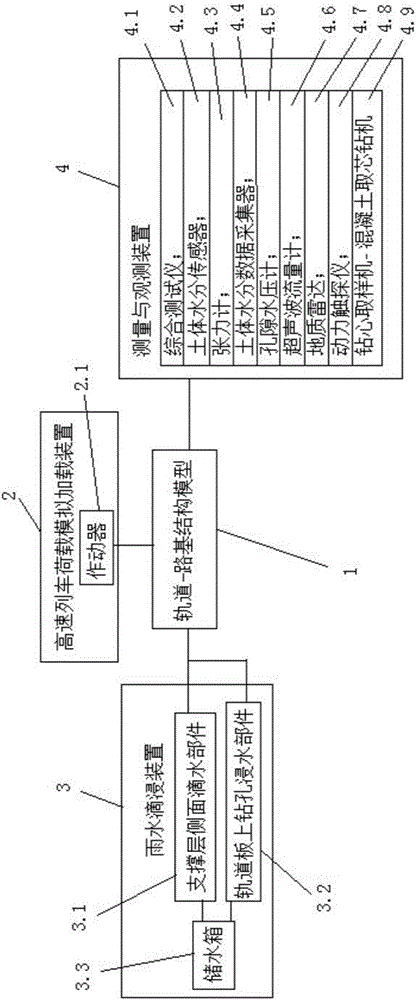

[0056] A high-speed railway ballastless track embankment mud pumping test method, including the following test system (see figure 1 ): Specifically including a track-subgrade structure model 1 with a scale of 1:1 to the actual track subgrade to be tested, a high-speed train load simulation loading device 2, a rainwater dripping device 3, and a measurement and observation device 4.

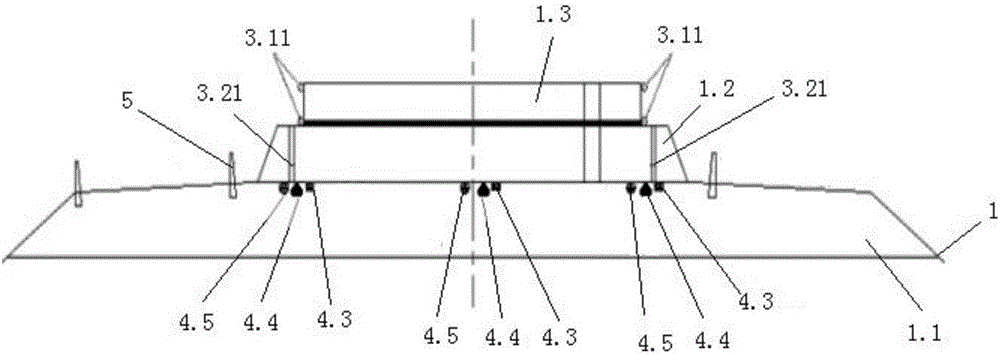

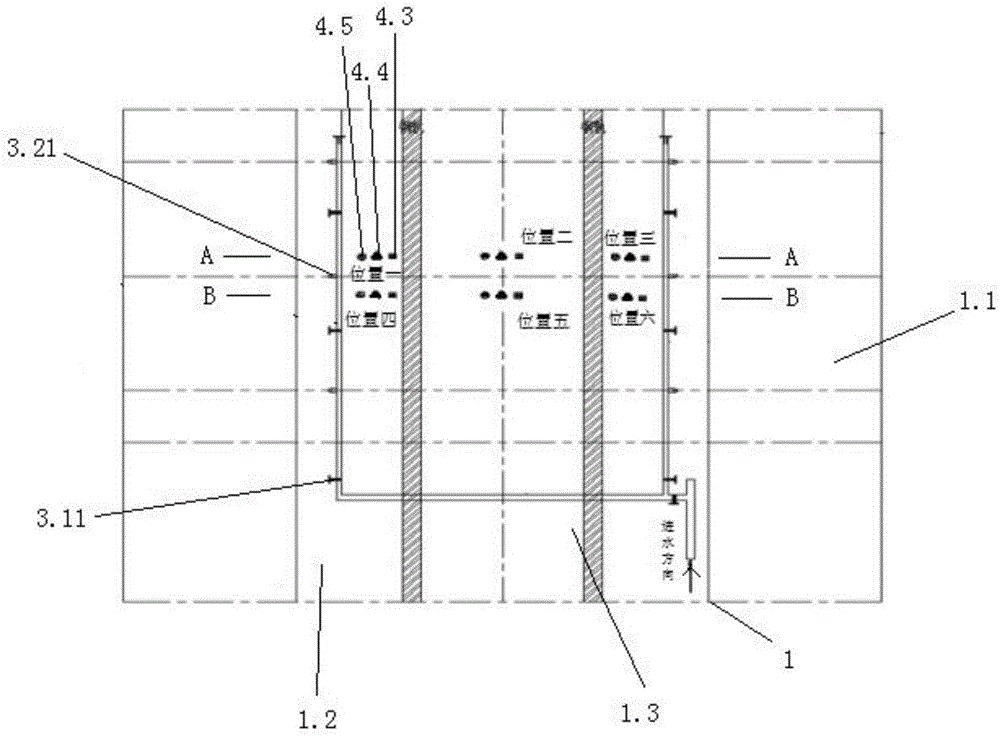

[0057] The track-subgrade structure model 1 is a two-way prestressed reinforced concrete structure (the track-subgrade structure model is a full-scale model of 1:1, and its construction materials and dimensions are the same as the actual track subgrade to be tested), which consists of the following The top includes bed layer 1.1, support layer 1.2 and track plate 1.3 in turn (see Figure 2-Figure 5 ), the thicknesses of the bed 1.1, the support layer 1.2 and the track plate 1.3 are 2700mm, 300mm and 200mm respectively; the bed layer 1.1 includes a lower bed layer with a thickness of 2300mm and an u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com