Automatic sample packaging mechanism based on sterility testing process

A detection process, fully automatic technology, applied in the direction of analyzing materials, instruments, etc., can solve problems such as error-prone, achieve perfect functions, realize fully automatic intelligence, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

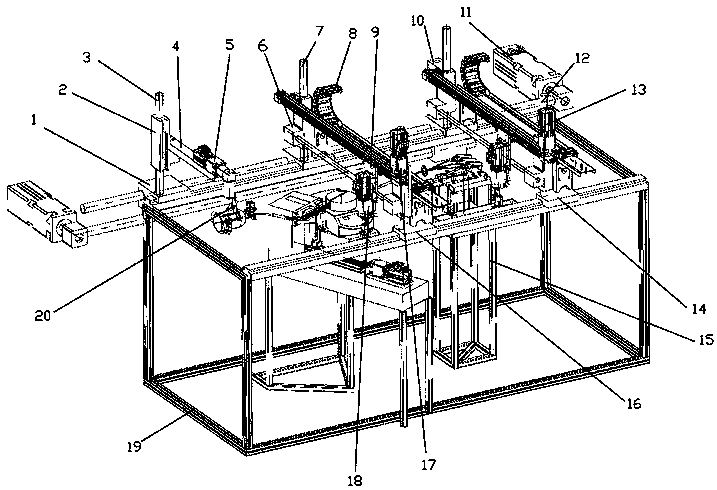

[0036] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0037] like figure 1 , figure 2 As shown, the overall mechanical structure mainly includes: the bacteria-collecting bottle needle grasping manipulator module, the bacteria-collecting bottle grasping manipulator module, the bacteria-collecting bottle installation module, the hose installation module, the hose flow-limiting module and the needle exchange module, among which :

[0038] The needle grabbing manipulator module for bacteria collection bottles includes: vertical slider 6; lead screw 7; cable bracket 8; motor support plate 9; stepping motor 11; bracket 14; Profile support 19; Coupling 21; Screw mandrel 22; Guide rail 23; Guide rail 24; Slide block 25; Guide rail 30; Slide block 32; Optical shaft 33; Figure 12 and Figure 13 .

[0039] Specific structure: the end of the servo motor 18 is a solenoid valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com