Bonding method for support pad of large-aperture reflecting mirror

A technology of large-diameter mirrors and support pads, used in installation, optics, instruments, etc., can solve the problems of unadjustable mirror position, uncontrollable thickness of the adhesive layer, and inability to place the mirror correctly, so that the thickness of the adhesive layer can be controlled. , The position accuracy and bond strength are satisfied, and the position accuracy is adjustable and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] In the present invention, the required tools and materials mainly include laser tracker, fishing line, scotch tape, hot melt glue, hot melt glue gun, hot blower, marker pen, 3M DP-2216, glue gun, rubber mixing tube, needle tube, A piece of rubber tube for static point, 240 sandpaper, rubber gloves, scissors, methylene chloride, acetone, ethanol, deionized water, dropper, absorbent paper, plastic wrap, etc.

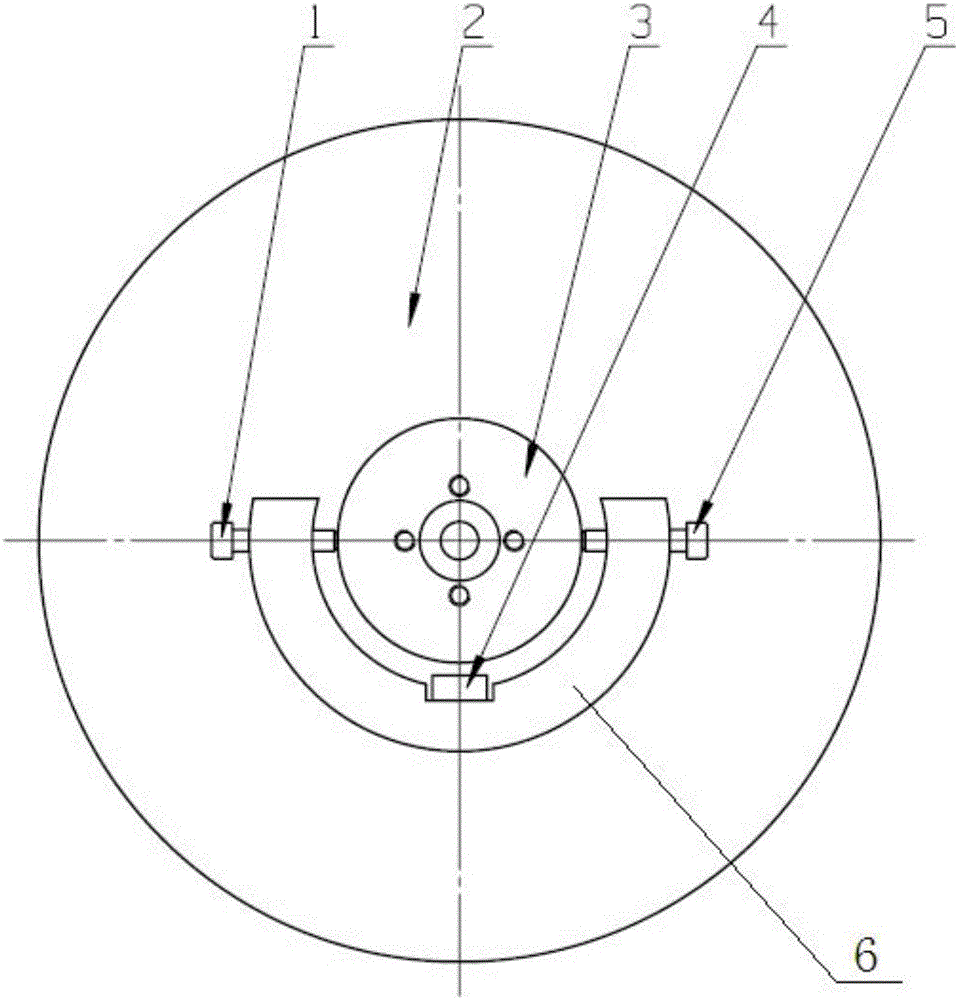

[0035] Such as figure 1 Shown, the bonding method of large-aperture reflector support pad of the present invention, its specific process is as follows:

[0036] Step 1. Rough positioning

[0037] Preliminary determination of the position of each support pad 3 on the mirror 2 by the laser tracker: place the laser tracker at an appropriate position, establish a coordinate system relative to the mirror 2, and place the target ball of the laser track...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com