Photomask structure and COA-type array substrate

A technology of a photomask and a light-shielding part, which is applied in the field of liquid crystal display device manufacturing, can solve the problems such as the thickness and slope of the color filter layer 200 are not easy to control, gas leakage, and reduce the pixel aperture ratio, so as to avoid poor display, ease the slope, The effect of improving the quality of electrical connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

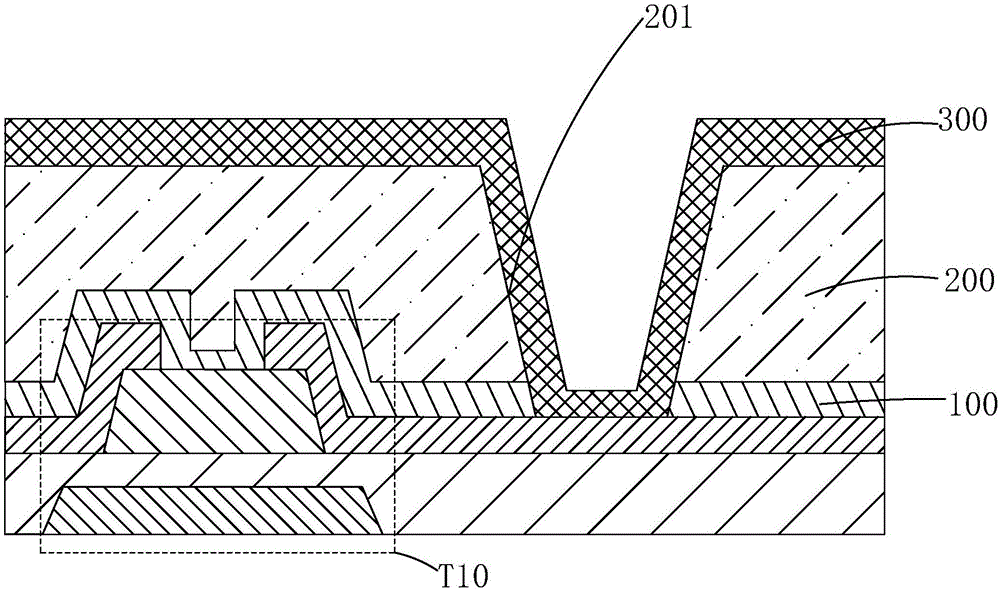

[0031] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

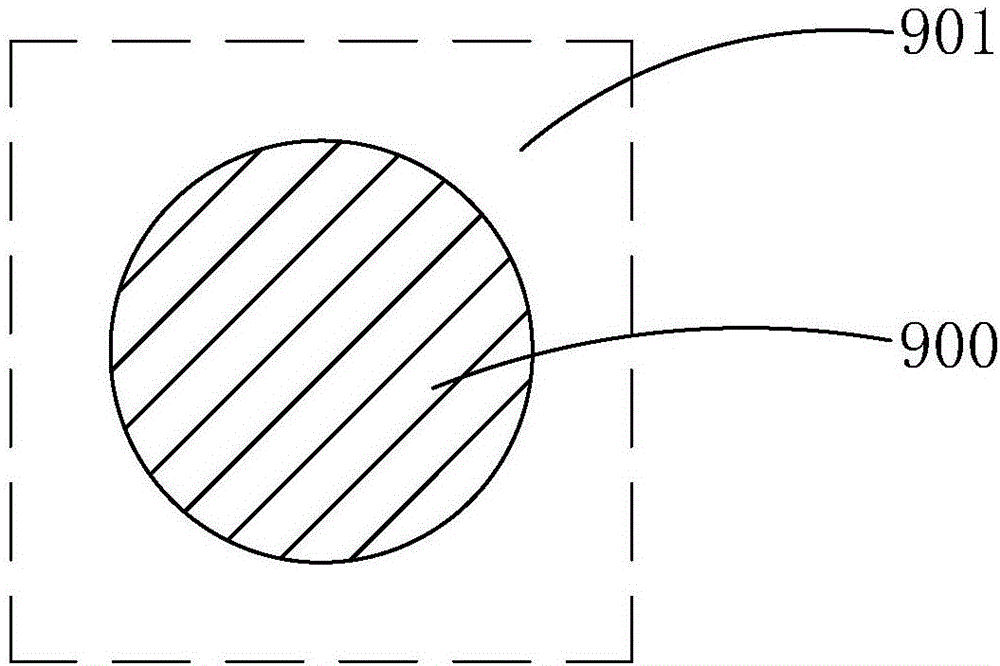

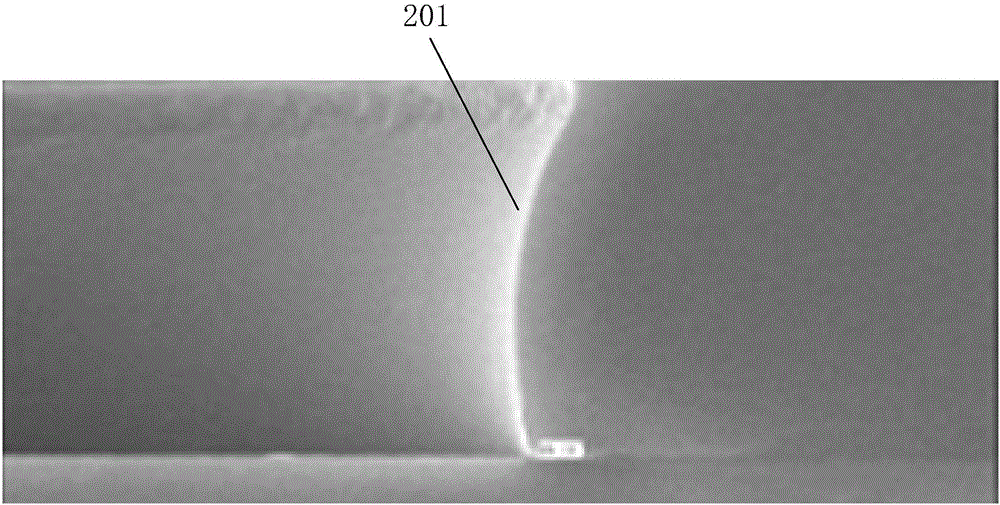

[0032] Please also see Figure 4 to Figure 7 , the present invention provides a photomask structure for making color filter layer via holes in a COA-type array substrate, the photomask structure includes a central light-shielding part 1, surrounding the central light-shielding part 1 and connecting with the outer surface of the central light-shielding part 1 The peripheral light-shielding part 3 with the same contour shape, and the ring-shaped hollow slit 5 sandwiched between the peripheral light-shielding part 3 and the central light-shielding part 1 .

[0033] The photomask of the present invention is used together with negative photoresist, and the pattern jointly formed by the central light-shielding part 1 , the hollow slit 5 , and the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com