Self-locking float level switch

A floating ball liquid level and switch technology, which is used in liquid level control, non-electric variable control, instruments, etc., can solve the problems of inability to lock, unstable shaking state, affecting the stable work of electrical appliances, and achieve reliable performance and convenience. The effect of promoting use and preventing random changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

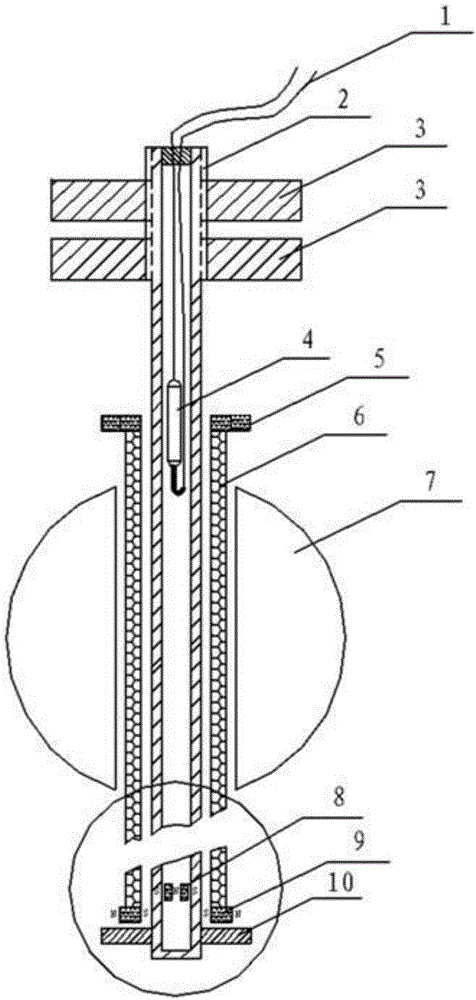

[0022] A self-locking float liquid level switch, including a closed non-magnetic tube 2, a reed switch 4 is arranged inside the non-magnetic tube 2, and two lead wires 1 at the top of the reed switch 4 are control signal lines, and the non-conductive tube 2 is provided with a reed switch 4. The top of the magnetic tube 2 is provided with a thread and two hexagonal nuts 3 for installation, which are used to install the self-locking float level switch.

[0023] The non-magnetic tube 2 is provided with a cylindrical passive buoy 6 that can float up and down along the non-magnetic tube 2. The specific gravity of the material used for the buoy 6 is not greater than that of the liquid. The stopper 10 for limiting the position in the direction; the cylindrical passive buoy 6 is covered with a buoy 7 which slides and fits with the buoy 6 .

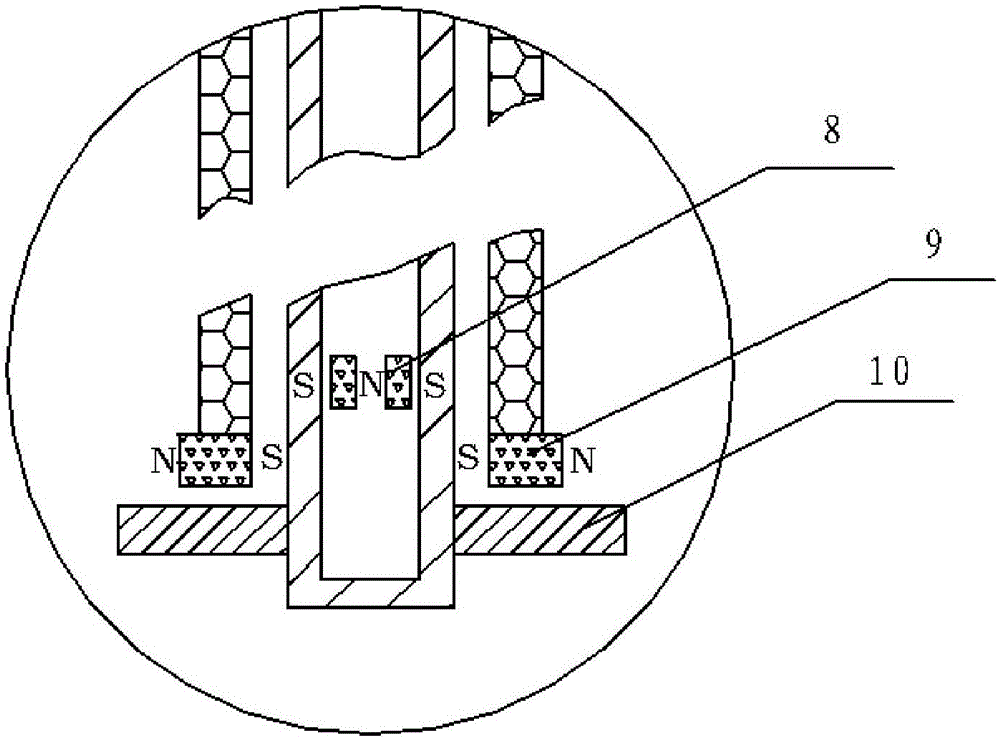

[0024] The two ends of the cylindrical passive buoy 6 are respectively provided with an upper magnetic limiting plate 5 and a lower magnetic limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com