Elastic vane propeller flow noise prediction method

A technology of elastic blades and prediction methods, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as not considering the fluid-structure two-way coupling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

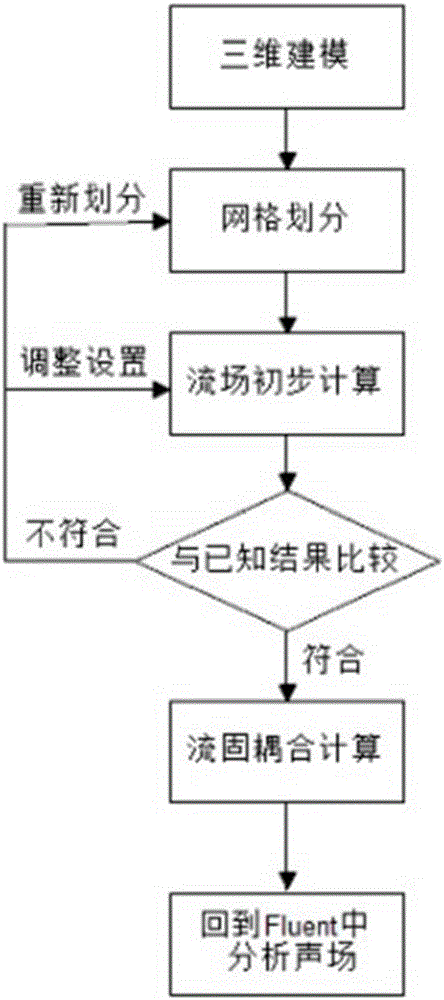

[0041] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

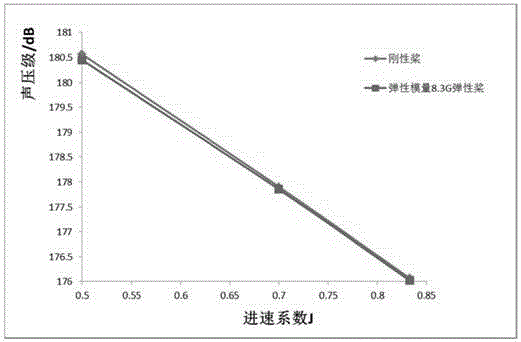

[0042] Such as figure 1 -6 shows:

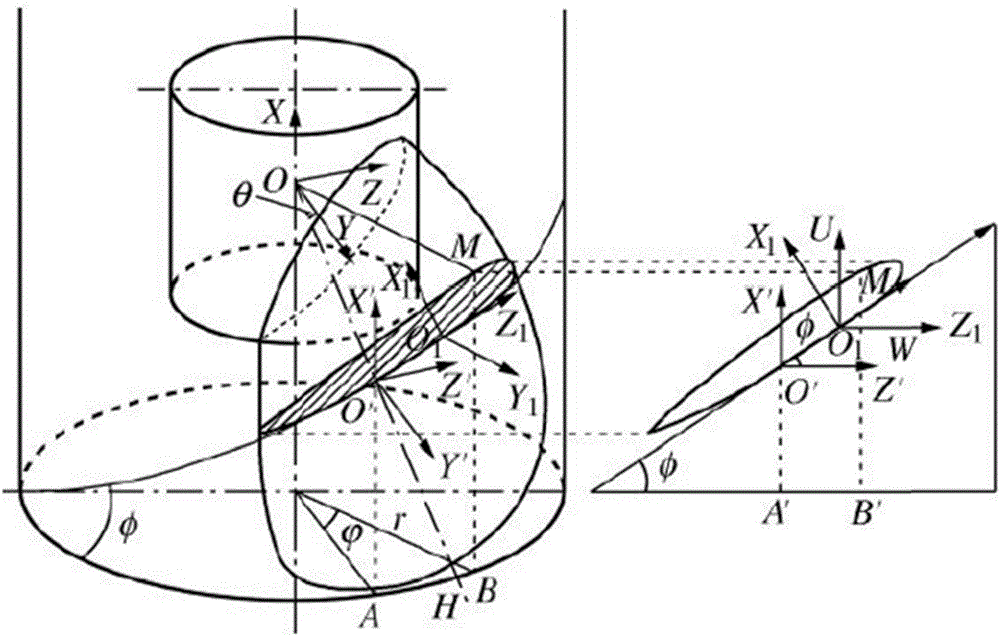

[0043] Step 1 geometric modeling: the software used in this step is Solidworks, according to figure 2 The schematic diagram of the propeller projection principle and the coordinate transformation formula are shown:

[0044]

[0045] Where: φ is the pitch angle; θ is the pitch angle; L is the distance between the maximum thickness line and the reference line; r is the blade cutting surface radius; X 1 , Y 1 ,Z 1 is the coordinate value in the local coordinate system; X, Y, Z is the coordinate value in the global coordinate system.

[0046] The two-dimensional plane coordinates of the DTMB 4119 propeller blade section can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com