Permanent magnet ferrite core forming quality control system

A technology of permanent ferrite and molding quality, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc. It can solve the problems of no practical guidance in production, easy deposition, long process time, etc., and achieve consistent weight improvement Sexuality, small amount of processing, and the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below, but the present invention is not limited to the following examples.

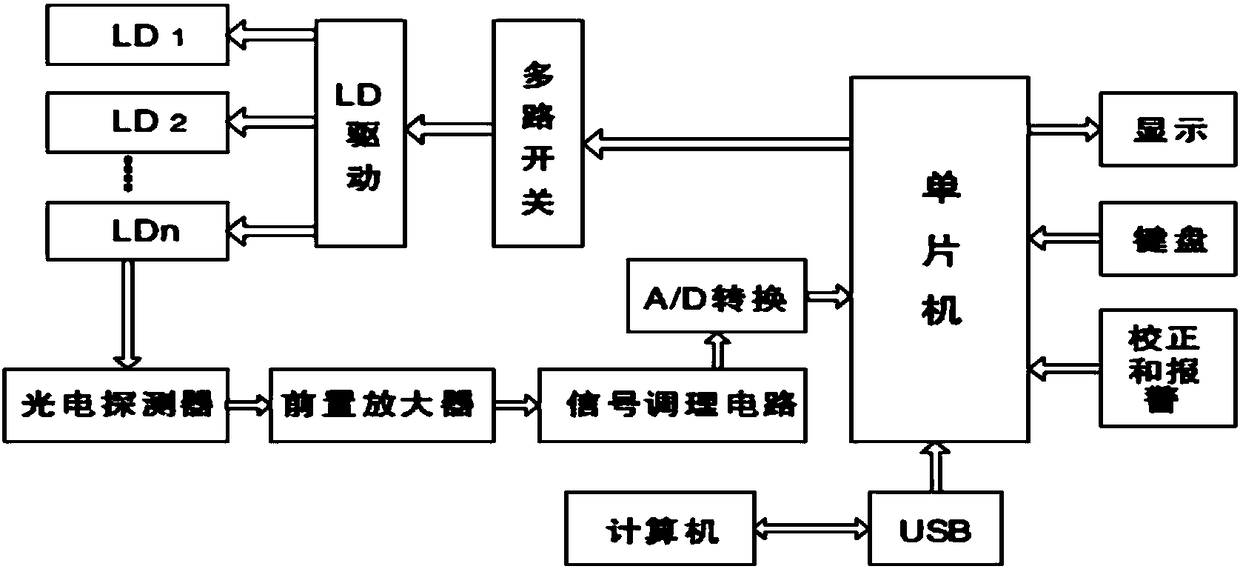

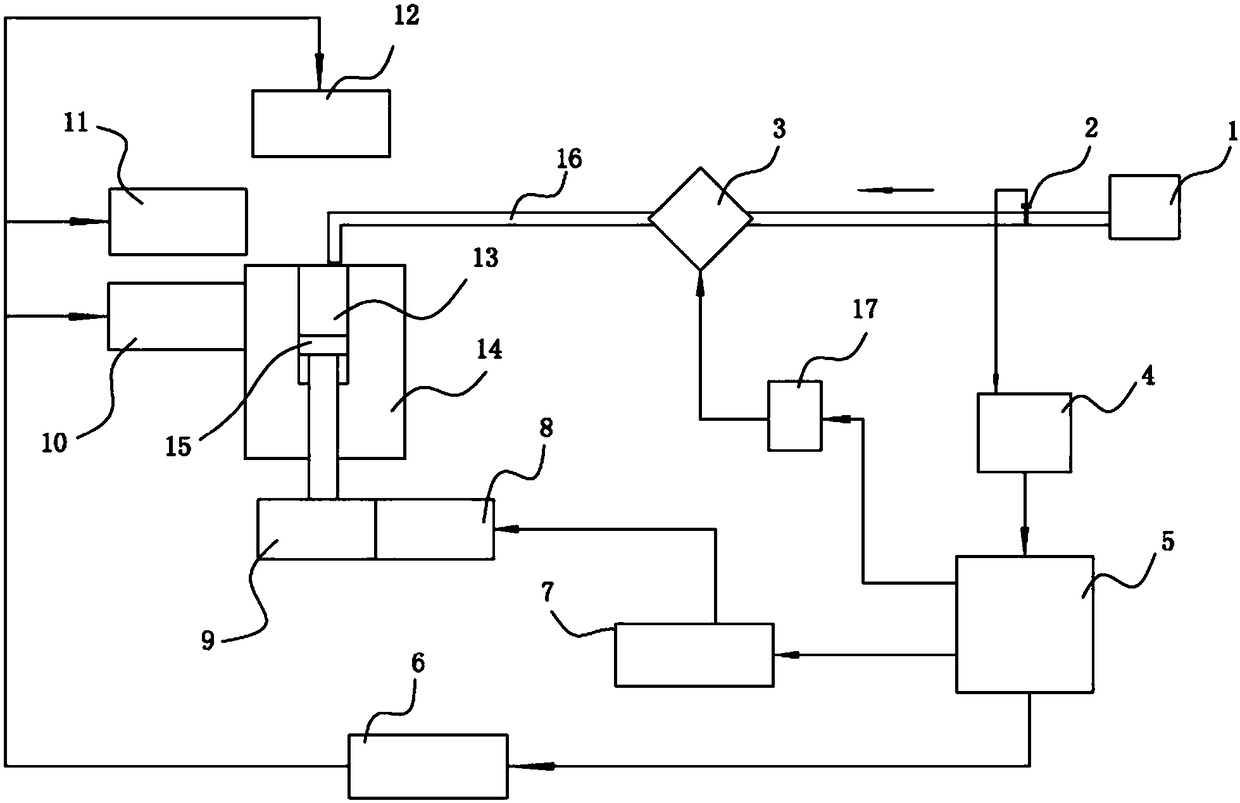

[0014] Such as figure 2 As shown, the permanent magnet ferrite core molding quality control system of the present invention includes a press 14 with a charging chamber 13, a delivery pipeline 16 for transporting slurry from the slurry tank 1 to the charging chamber, and adjusting charging The transmission mechanism 9 for the capacity of the chamber, the water absorption mechanism 10 for absorbing the slurry moisture in the charging chamber, the scraping mechanism 11 for scraping the excess slurry on the top of the charging chamber, and the pressing mechanism 12 for applying pressure to the slurry. The above-mentioned structure of the present invention is similar to the prior art, and will not be described in detail here.

[0015] A probe-type sensor 2 is provided on the conveying pipeline, and the probe-type sensor is inserted radially into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com