Liquid flow box for liquid flow battery and single battery thereof

A technology of liquid flow battery and liquid flow frame, which is applied in the direction of fuel cells, circuits, electrical components, etc., and can solve the problems of affecting the overall performance and operating costs of the system, burning out the isolation film, conductive plastic plate electrodes, and inability to collect single-cell voltage, etc. problems, to achieve the effect of promoting large-scale batch production and application, high installation success rate, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

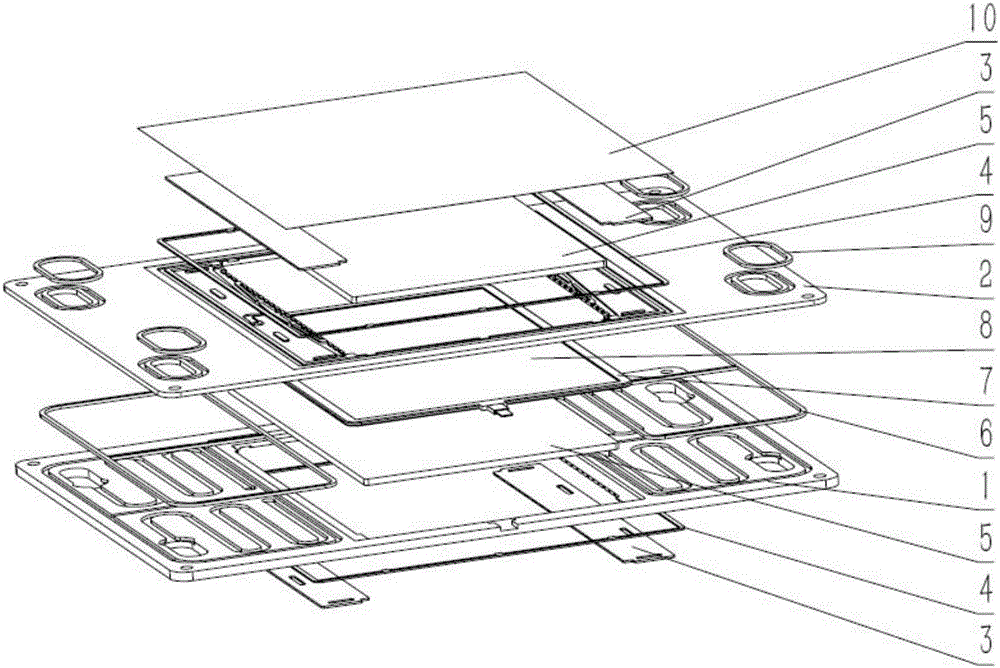

Image

Examples

Embodiment Construction

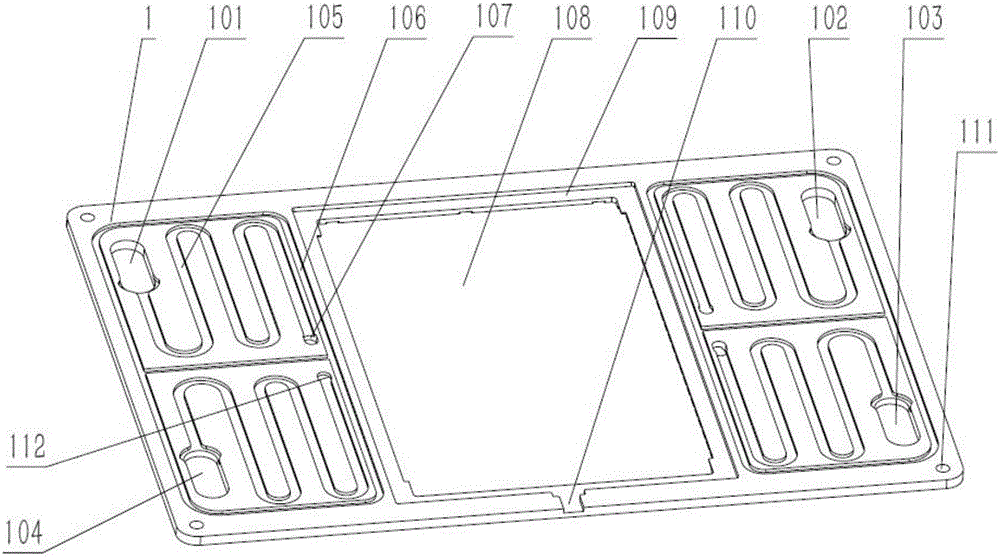

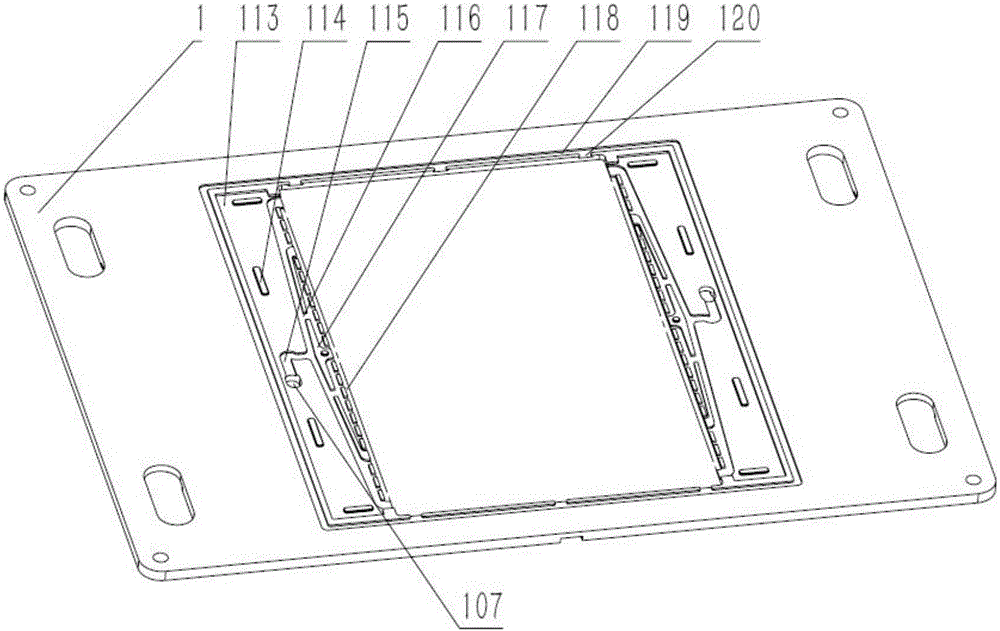

[0034]In the existing patented technology, there is no liquid flow frame with a working temperature higher than 70 °C, and to solve the problem of internal leakage between the electrodes and the leakage between the liquid flow frame; secondly, there is no isolation film protection tank, which is easy to damage or damage the isolation film; again , the liquid flow frame is not equipped with a conductive bipolar plate for external taps, and the voltage of each single cell of the stack cannot be collected. In addition, the flow uniformity of the liquid flow frame in the existing patent is not as good as that of the present invention. The flow uniformity channel of the present invention adopts a "eight"-shaped structure, and is equipped with a flow balance block and a flow uniformity groove, and the flow uniformity is greater than that of the present invention. 99%; the liquid flow frame of the present invention is provided with positioning pin holes, which is convenient for instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com