Wireless network based remote monitoring system for sewing equipment

A remote monitoring system and wireless network technology, applied in the field of sewing equipment remote monitoring system, can solve problems such as failure to collect operating data and operation data, increase service costs, illegal use of equipment, optimization of factory production processes, etc. The effect of lease management, improving service level and overall efficiency, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

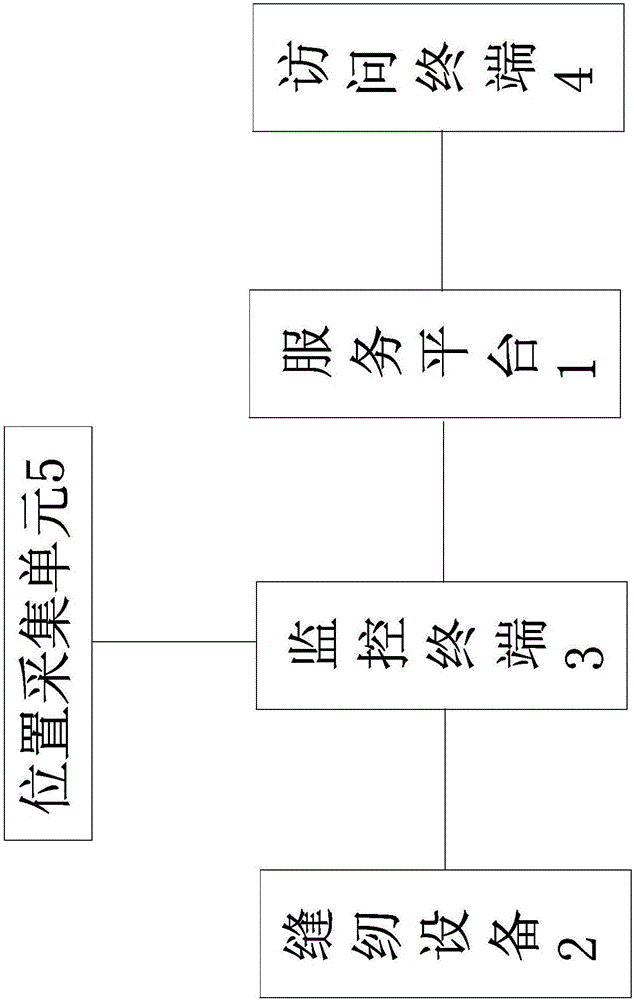

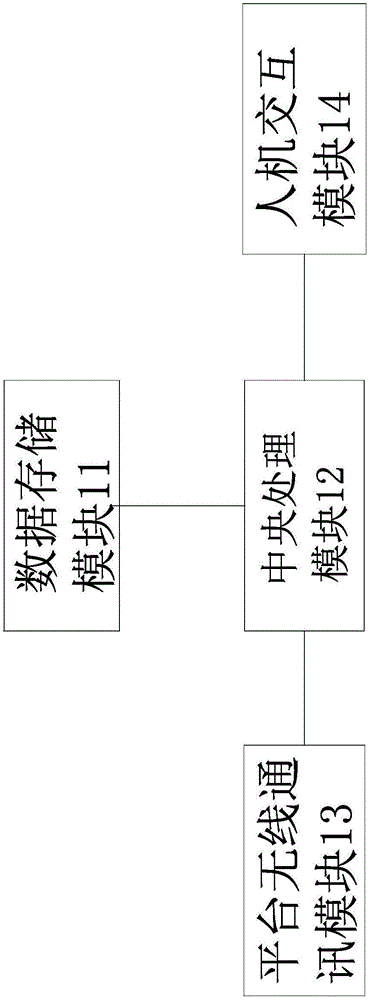

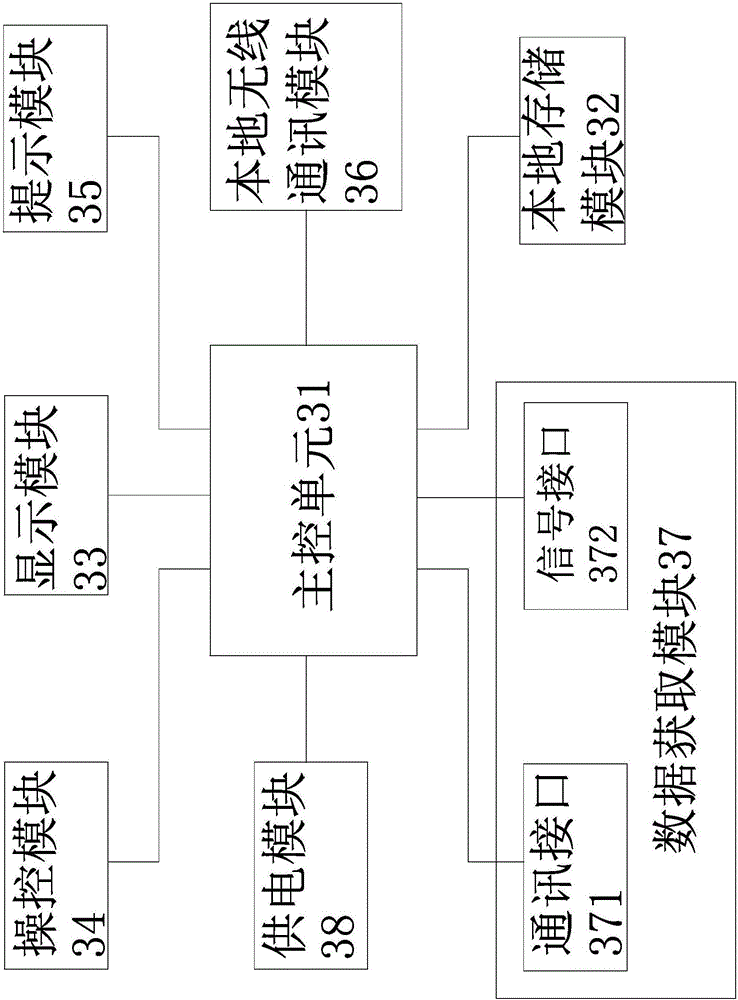

[0034] like figure 1 As shown, this remote monitoring system for sewing equipment based on wireless network, this system includes a service platform 1 and at least one monitoring terminal 3 set on the sewing equipment 2, the monitoring terminal 3 is set on the panel of the sewing equipment 2 or on the sewing equipment 2 On other components, the monitoring terminal 3 is set in one-to-one correspondence with the sewing equipment 2, and the service platform 1 is connected to each monitoring terminal 3 through a wireless network; the monitoring terminal 3 is configured to be able to obtain the corresponding sewing equipment 2, including various operating data and Equipment data including operation data and the obtained equipment data are transmitted to the service platform 1 through the wireless network, and the platform data including th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com