Forming and packaging equipment of annular packing boxes

A technology for packaging equipment and packaging boxes, which is used in packaging, transportation and packaging, and box making operations. Accuracy and other issues, to achieve the effect of strong equipment continuity, strong equipment adaptability, and optimized production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

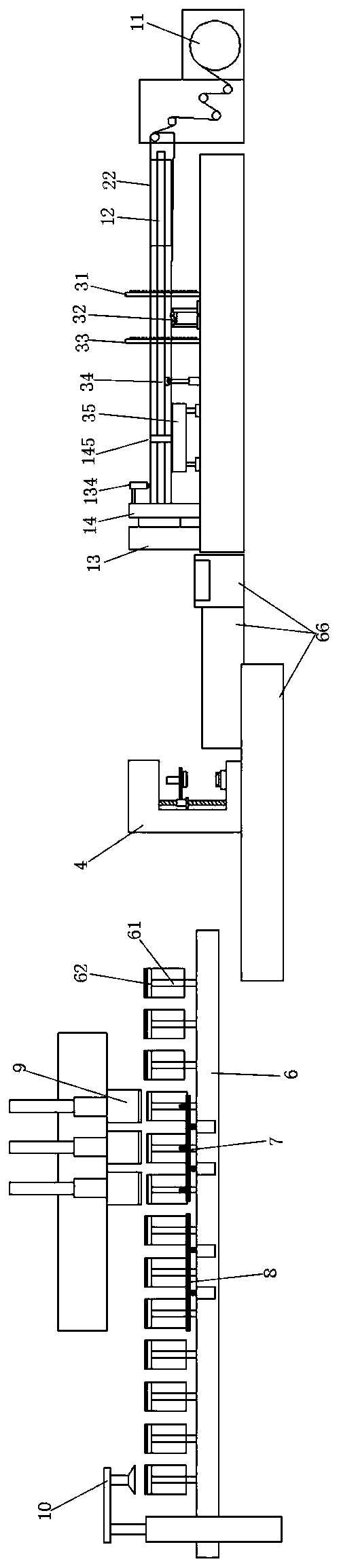

[0025] refer to figure 1 As shown, an ultrasonic packaging device for a ring-shaped packaging box includes a forming and cutting section, a crimping section, and a capping section that are butted by a conveyor belt 66 . Conveyor belt 66 is used to convey the ring-shaped packaging of each link, and provides transportation services for plastic sheets from conversion molding to ring-shaped packaging, crimping, and upper cover packaging. Materials can be picked up manually and put into corresponding sections for production, or they can be produced through multi-directional The robotic arm picks up the material.

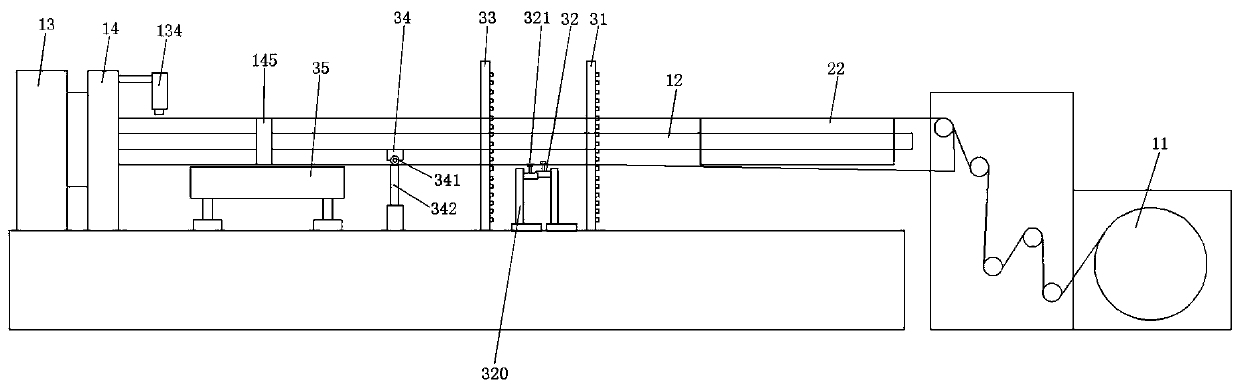

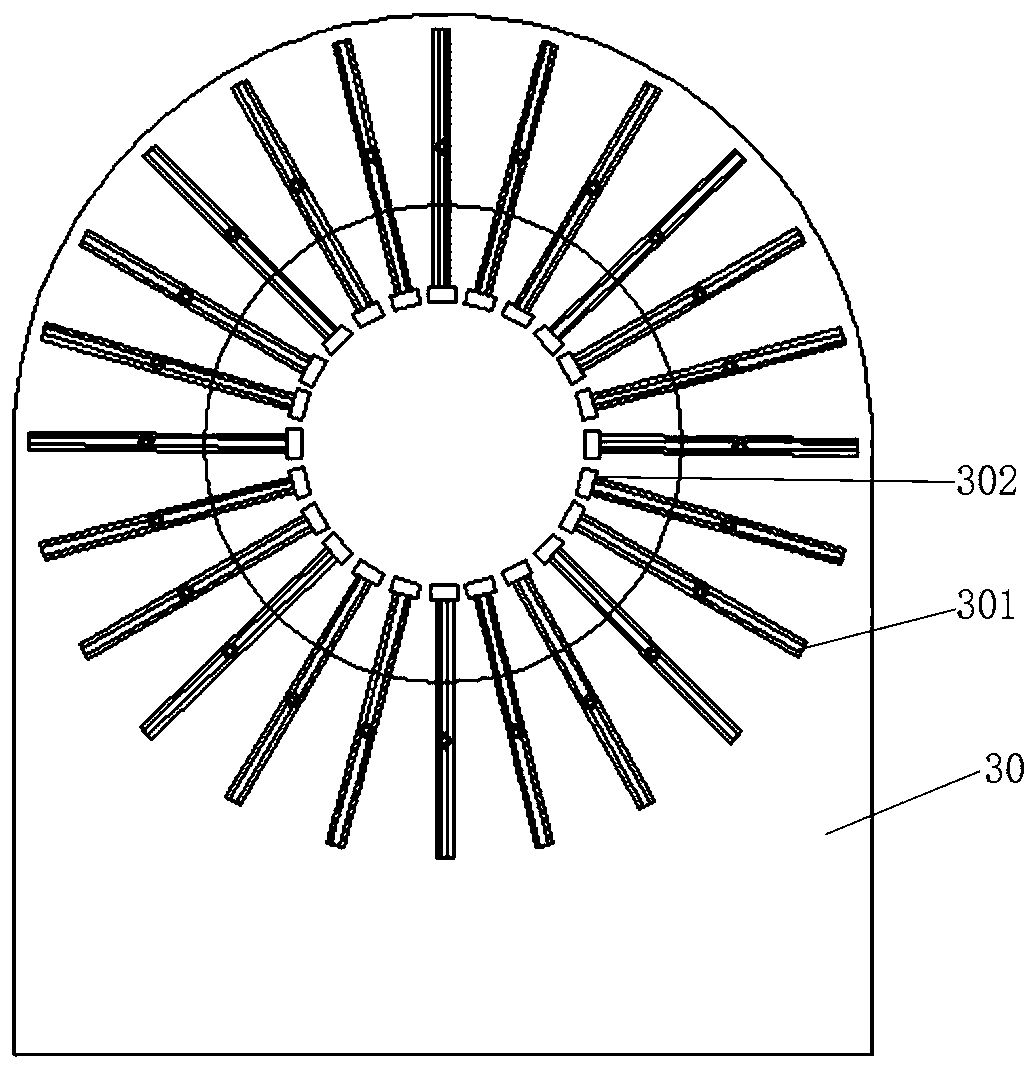

[0026] Such as figure 2 , image 3 As shown, the forming and cutting section is composed of an unwinding mechanism 11, a central shaft 12 and a rotary cutting mechanism 13. A propulsion mechanism 14 is provided between the central shaft 12 and the rotary cutti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com