Device for processing carbon rod electrode

A carbon rod electrode, carbon rod technology, applied in the direction of stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of high test cost, low electrode qualification rate, large quantity, etc., to achieve easy maintenance and maintenance, increase The effect of collecting devices and equipment is easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

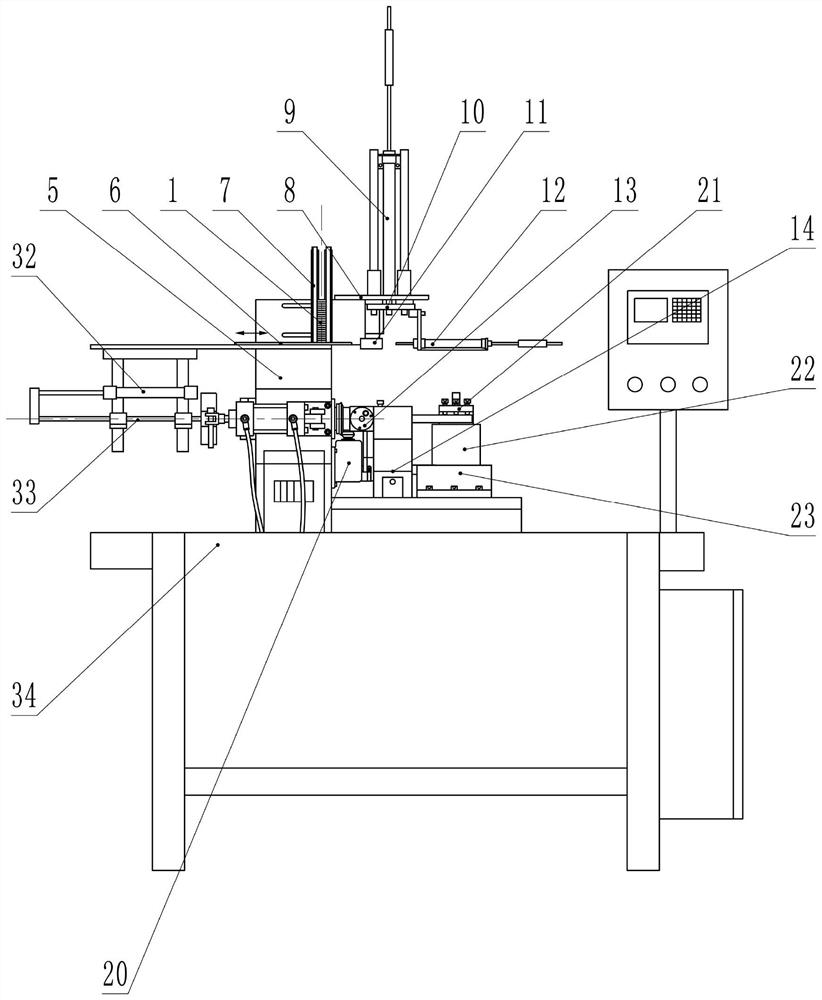

[0025] Such as Figures 2 to 11 As shown, the present invention includes a lathe body, a feeding servo mechanism and a dust collection device.

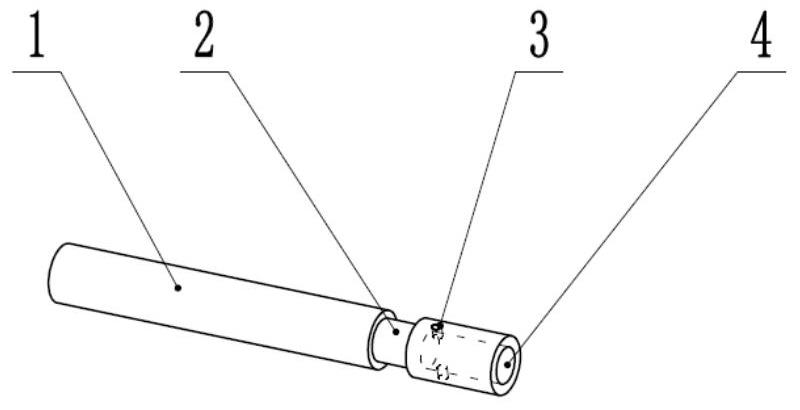

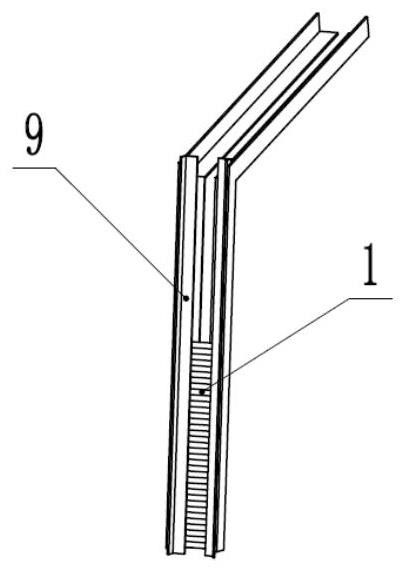

[0026] The feeding servo mechanism includes a magazine 7 , a first cylinder 19 , a loading frame, a second cylinder 9 , a third cylinder 12 and a fourth cylinder 32 . Such as image 3 As shown, the magazine 7 is used to place the graphite carbon rod 1 to be processed, the carbon rod 1 is placed horizontally in the magazine 7, and the lower end of the magazine 7 is provided with an opening along the length direction of the carbon rod 1 . The piston rod of the first cylinder 19 is provided with a first cylinder pusher rod 6, and the end of the first cylinder pusher rod 6 faces the carbon rod 1 at the bottom of the magazine 7, and the first cylinder is driven by the first cylinder 19 The push rod 6 pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com