A strip continuous casting and rolling induction heating device

An induction heating device, continuous casting and rolling technology, applied in the direction of induction heating device, induction heating, electric heating device, etc., can solve the problems that affect the rhythm of the production line, cannot be adjusted flexibly, and the safety and stability need to be improved, so as to improve product quality and Market competitiveness, increasing convenience and safety performance, and the effect of efficient and rapid continuous heating treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

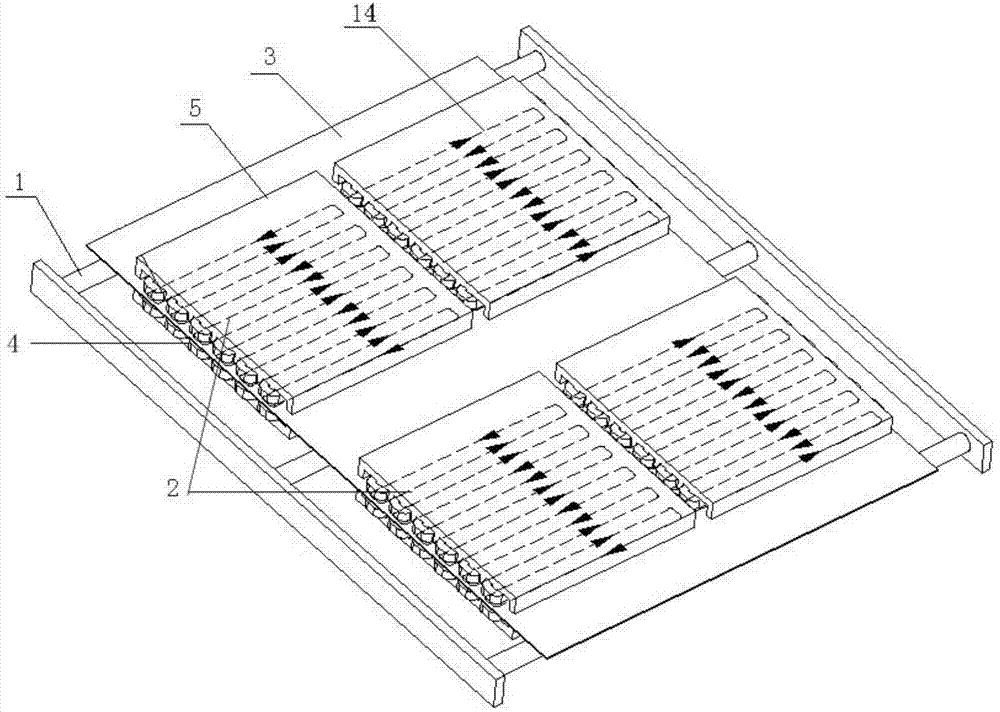

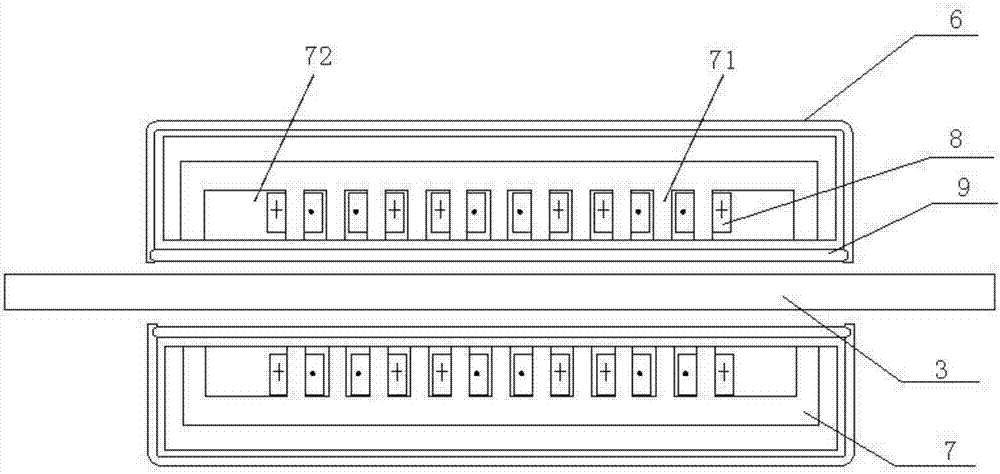

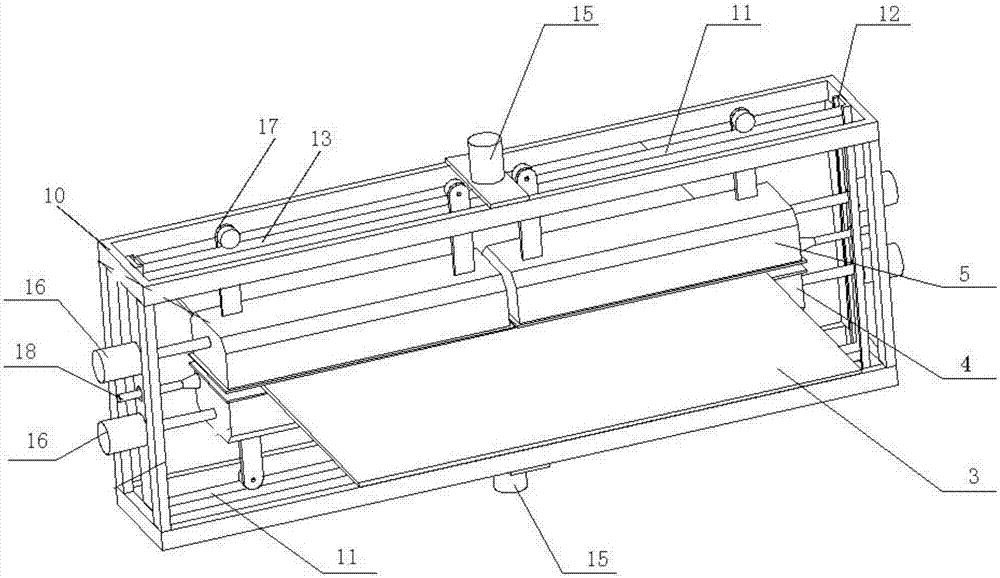

[0028] Such as figure 1 and figure 2 As shown, the strip continuous casting and rolling induction heating device provided by the present invention includes a plurality of induction heaters 2 arranged side by side with interval conveying rollers 1, and each induction heater 2 includes two pairs along the width of the strip 3. The planar inductors arranged side by side in the width direction; the currents of the two pairs of planar inductors arranged side by side in the width direction are the same in size and opposite in direction, and the middle parts of the two induced current circulations in the strip can be superimposed on each other to achieve the purpose of energy saving; The plane inductor is made up of the plane inductor 4 of the lower floor and the plane inductor 5 of the upper floor; the plane inductor 4 of the said lower floor and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com