Sulfur-crosslinkable rubber mixture and vehicle tire

A rubber compound and vehicle technology, applied in special tires, vehicle parts, tire parts, etc., can solve the problems of rubber compound tear resistance, wet grip index degradation, etc., to achieve short complete curing time, good processability, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

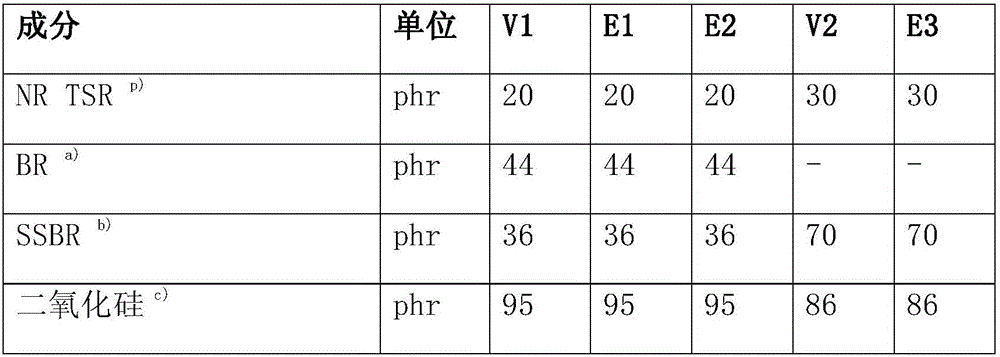

[0151] The invention will now be described in detail with the aid of comparative examples and examples, which are summarized in Tables 1 to 4.

[0152] Comparative mixtures are identified by V and inventive mixtures by E.

[0153] The mixture production is carried out in a laboratory mixer with a volume of 300 microliters to 3 liters under usual conditions in two hours according to the usual methods in the rubber industry, wherein firstly in the first mixing step (basic mixing step) All ingredients except the curing system (sulfur and substances affecting curing) were mixed at 145°C to 165°C for 200 to 600 seconds with a target temperature of 152°C to 157°C. The finished mixture is produced by adding the curing system in a second step (the finished mixing step), where it is mixed at 90°C to 120°C for 180 to 300 seconds.

[0154] General methods for producing rubber compounds and their cured products are described in "Handbook of Rubber Technology", W. Hofmann, Hanser Verlag 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com