System for monitoring physical parameters of textile machinery and method for predictive maintenance

A textile machinery and physical technology, applied in the field of monitoring systems of textile machinery, can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

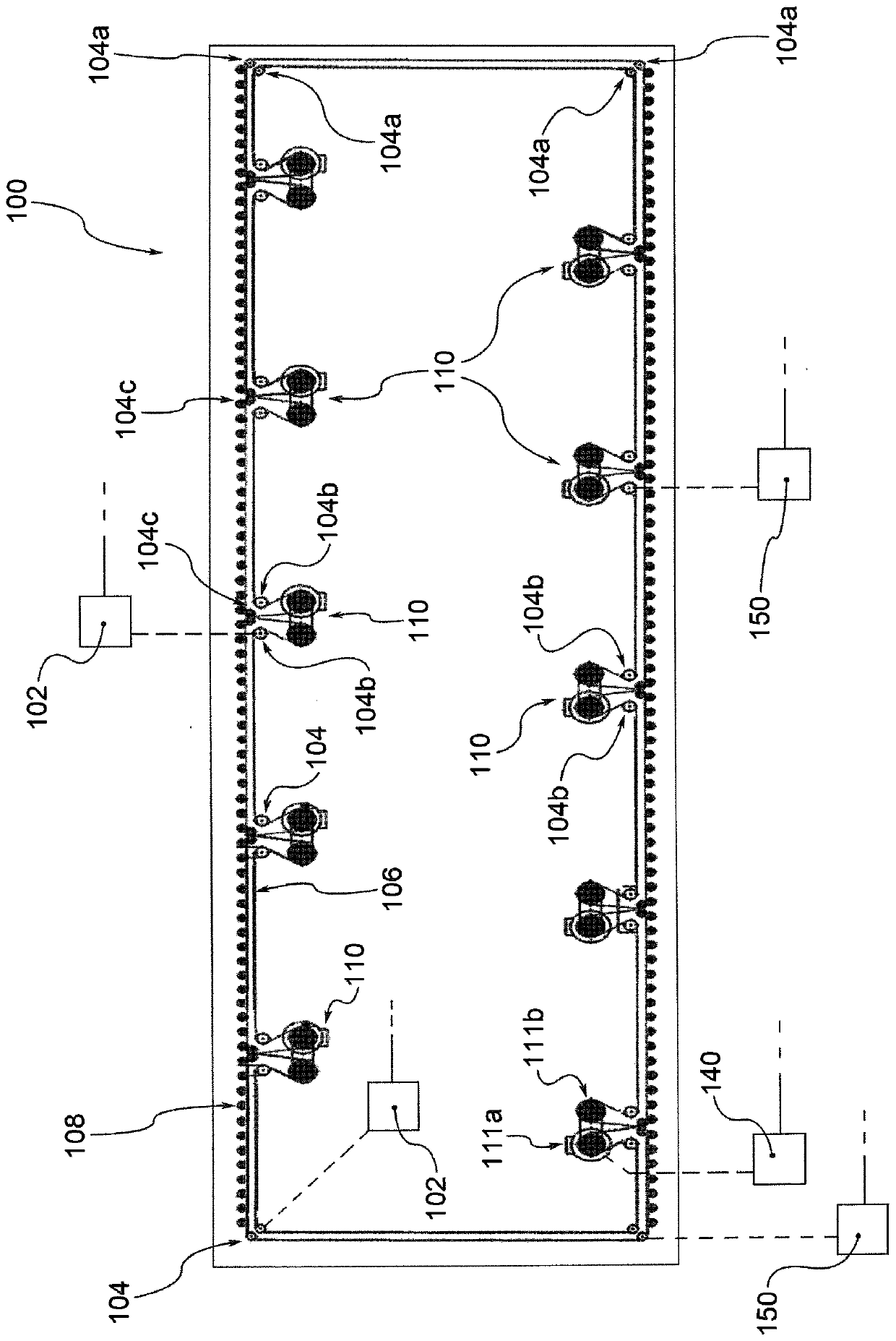

[0029] According to yet another embodiment, the detection device is adapted to provide a force value; for example, the detection device is a force sensor, such as a load cell, adapted to detect the tension of a belt of the machine.

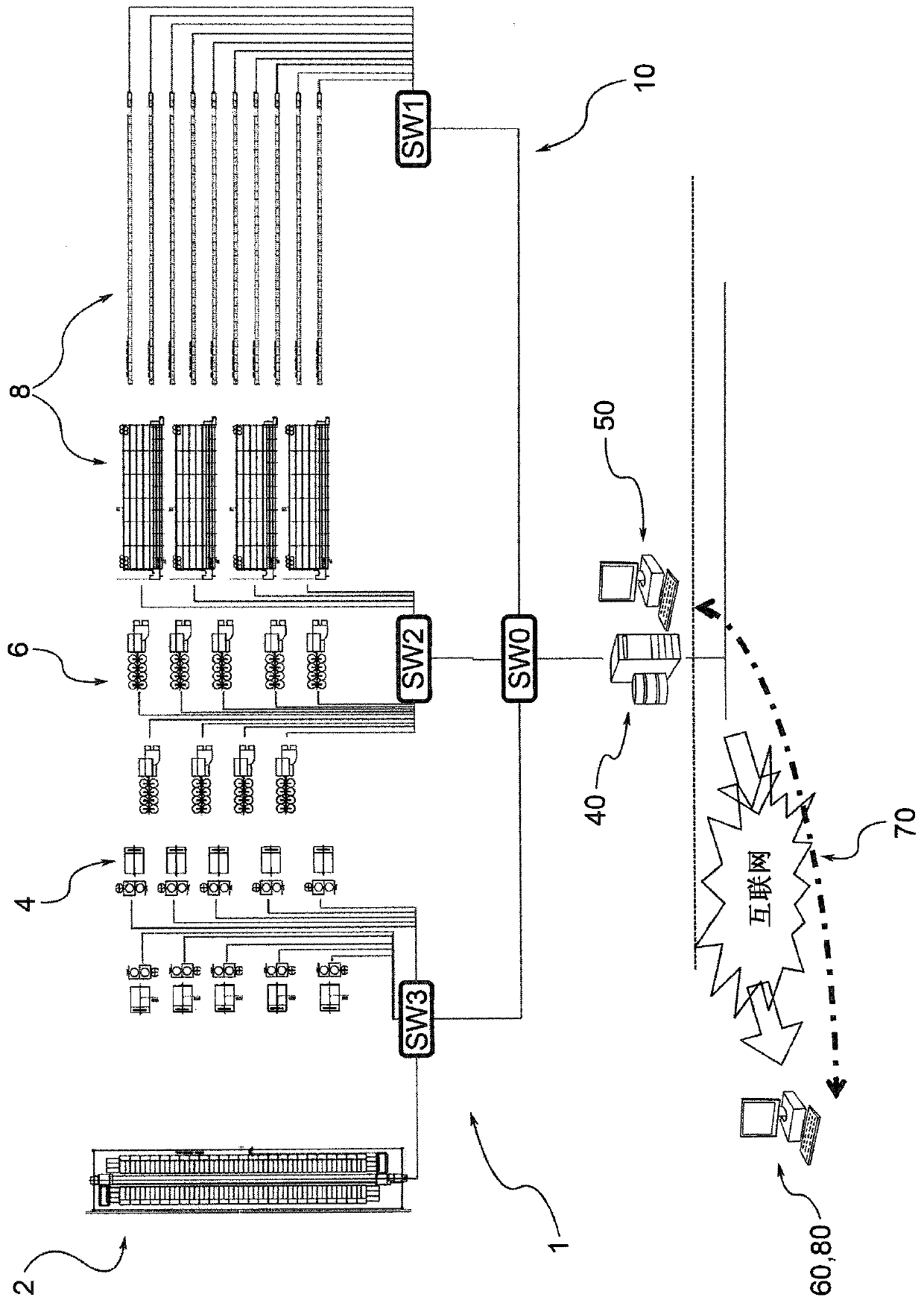

[0030] Furthermore, each machine 2, 4, 6, 8 is provided with a control unit for managing the process, which control unit itself detects (and possibly stores) status data of the respective machine, such as the speed of one or more mechanisms, absorption Electricity, current drawn by motors, temperature of certain mechanisms, etc.

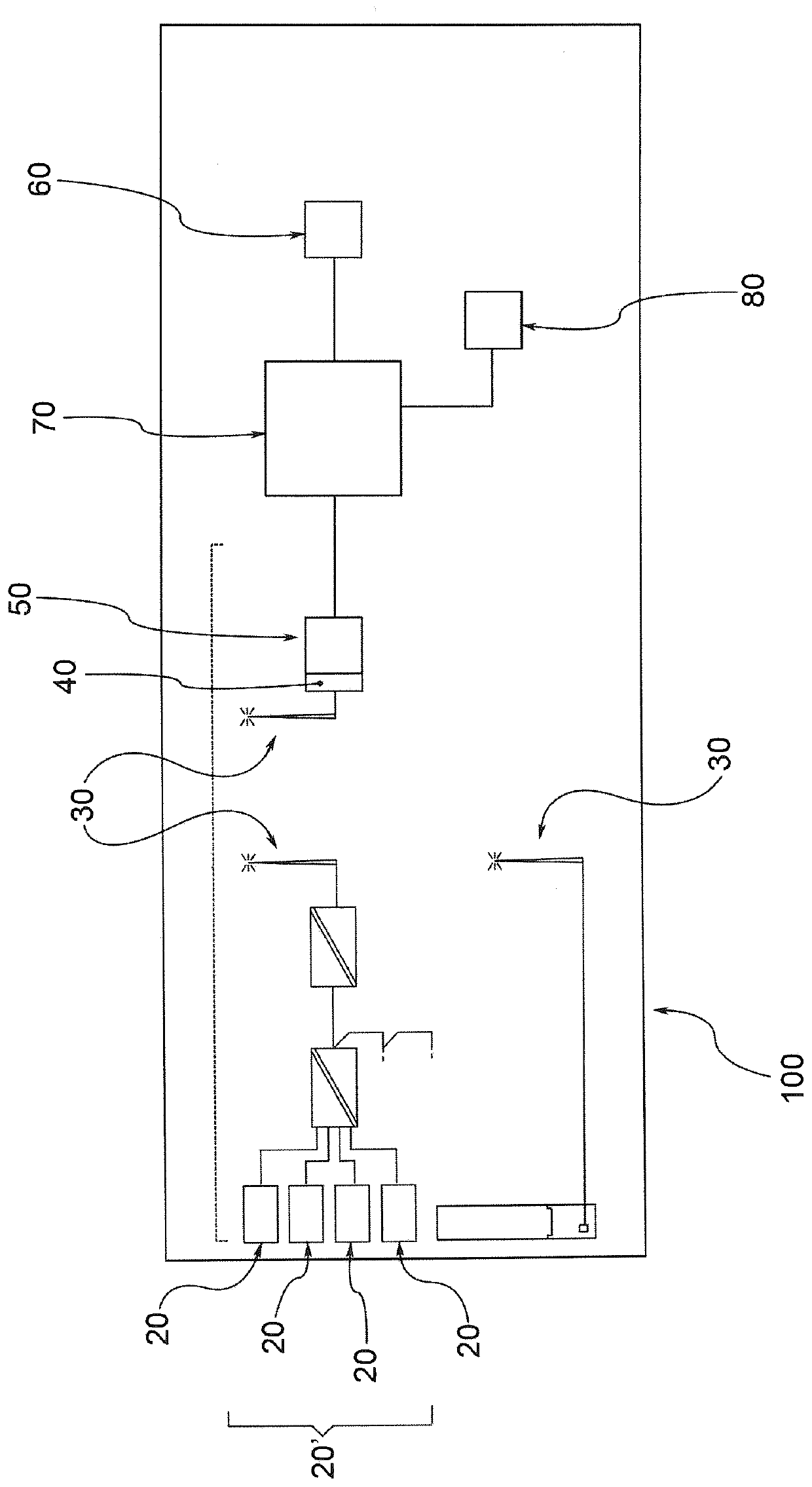

[0031] Preferably, in addition, the local device comprises image acquisition means, eg at least one webcam for capturing images related to the machine or its mechanisms.

[0032] According to a preferred embodiment, according to figure 2 , the monitoring system also includes local transmission / reception means 30, for example using wireless (Wi-Fi type) technology, installed in the textile mill, operatively connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com