Bearing units for deep drilling units

A bearing device and deep drilling technology, which is applied in the direction of rotating bearings, bearings, ball bearings, etc., can solve the problems of large structural space, increased radius of direction change, etc., and achieve small radius, increased overturning moment, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

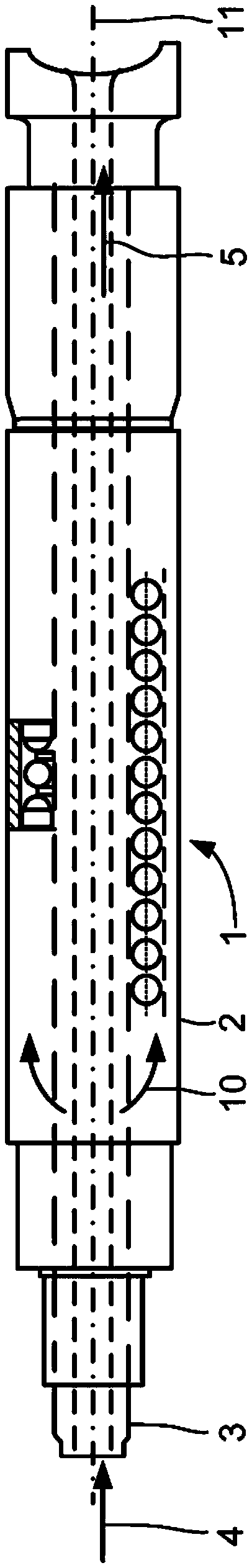

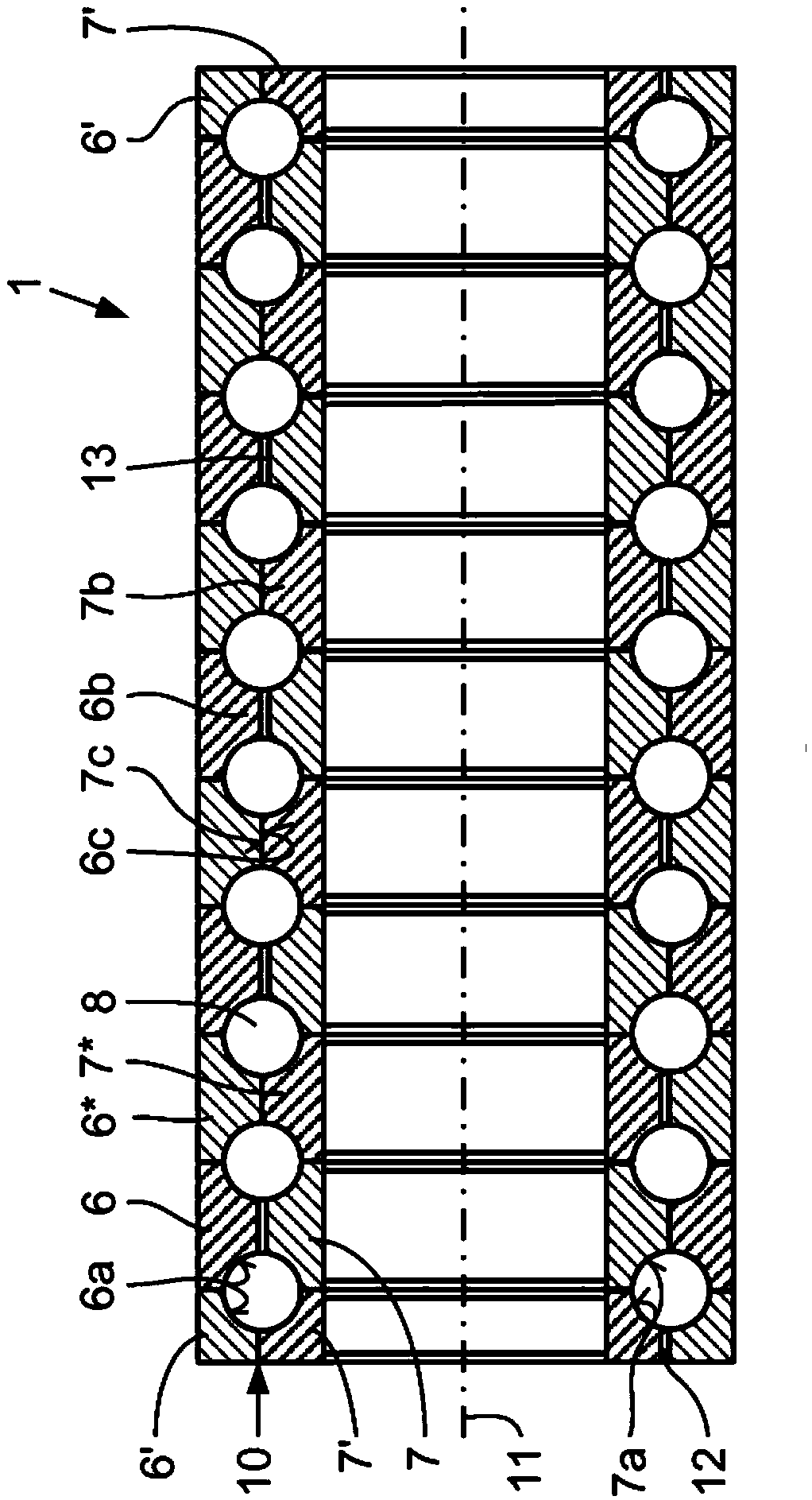

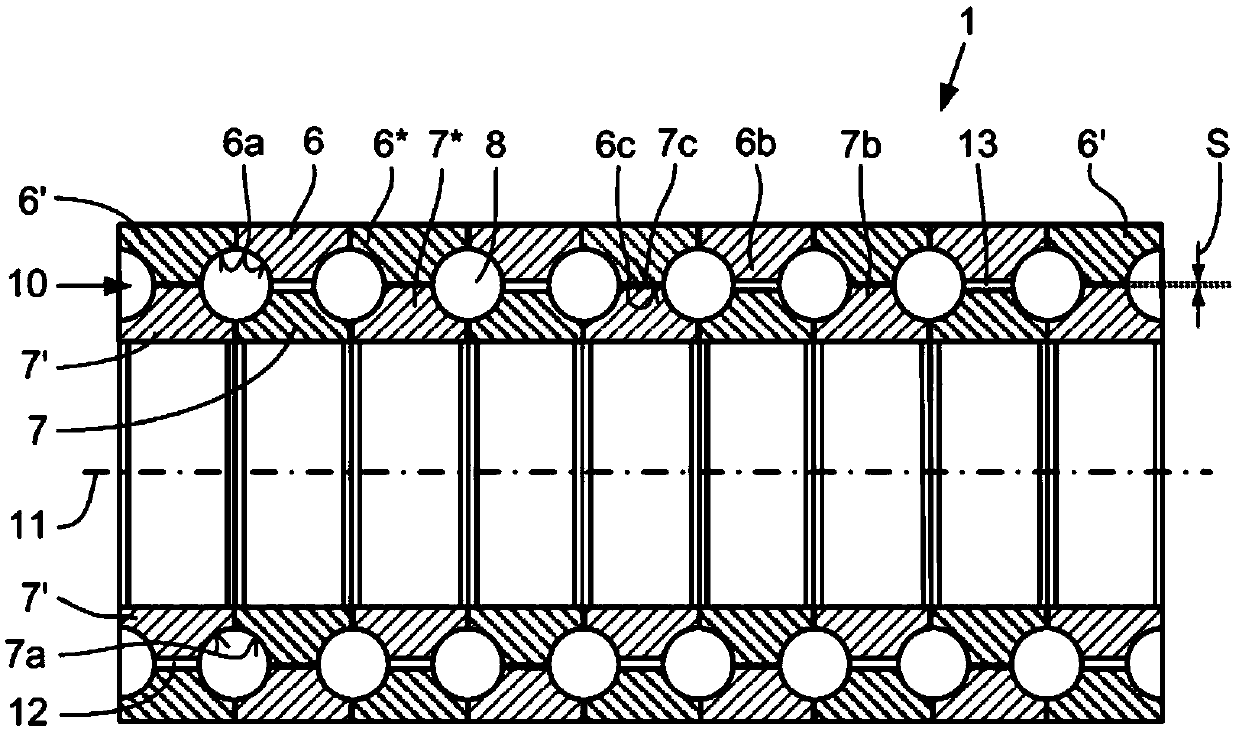

[0016] Thus, in figure 1 The bearing arrangement 1 of the drive shaft of the drill is shown. The drive shaft is arranged radially within the bearing arrangement 1 and is designed as a hollow shaft 3 . The hollow shaft 3 is supported in the torsion-resistant housing 2 by means of the bearing arrangement 1 and transmits the drive torque from the drive turbine (not shown) to the drill bit (not shown). According to the flow direction 4 , a flushing liquid is introduced into the hollow shaft 3 , with which the drive turbine is operated. Axially upstream of the bearing arrangement 1 , a portion of the flushing liquid is guided into the bearing arrangement 1 through the outlet 10 in the hollow shaft 3 in order to cool and lubricate the rolling bearing arrangement there, as well as in the plain bearings integrated into the bearing arrangement A carrier film is formed. The drill bit is then cooled and lubricated by the bulk of the flushing liquid flowing from the opening through whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com