A kind of active industrial flue gas final purification method

An industrial flue gas, active technology, applied in chemical instruments and methods, separation methods, gas treatment and other directions, can solve the problems of weak demineralization ability, low demisting efficiency, influence of demisting stability, etc., to reduce pollution, The effect of high flue gas purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

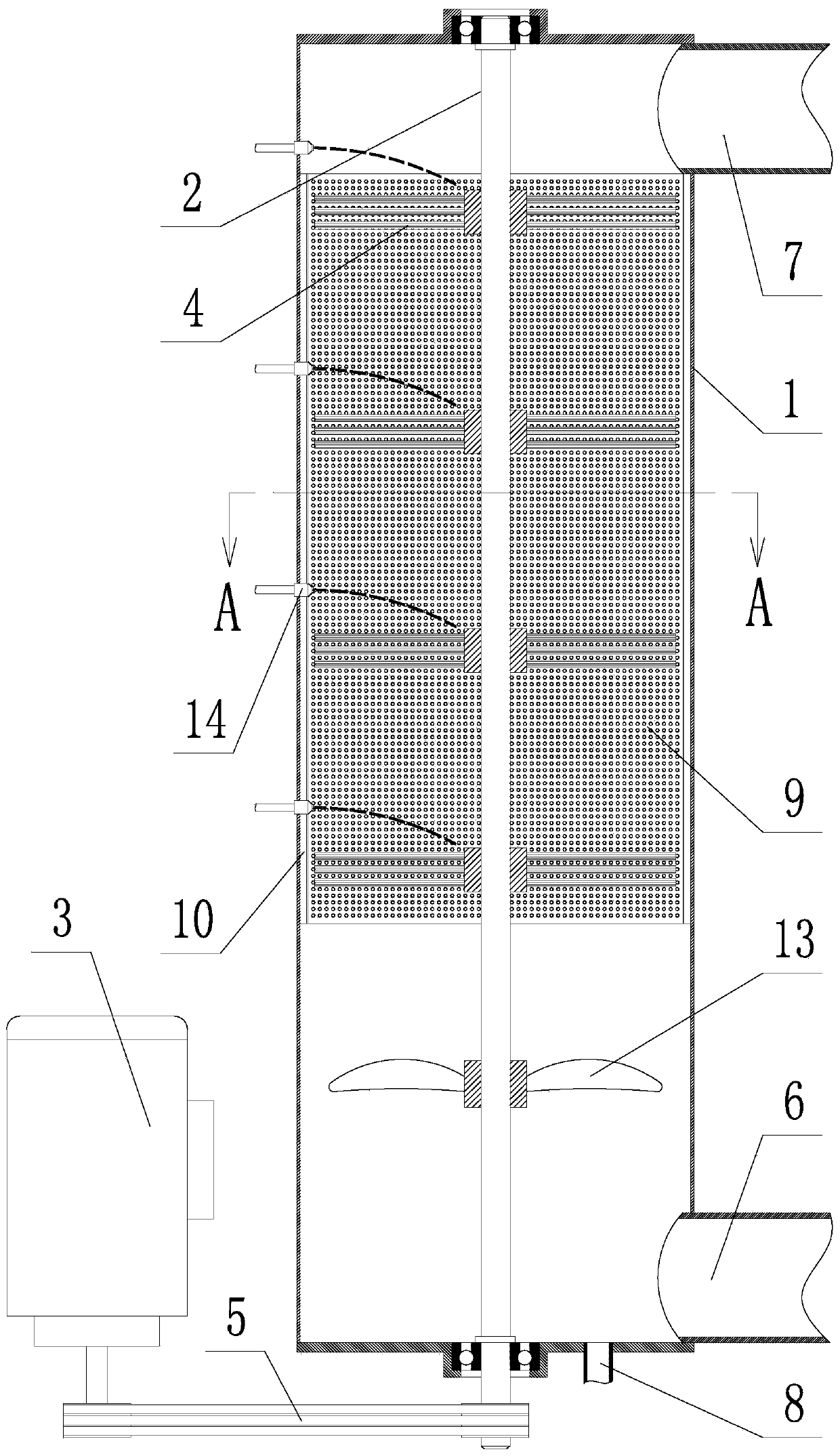

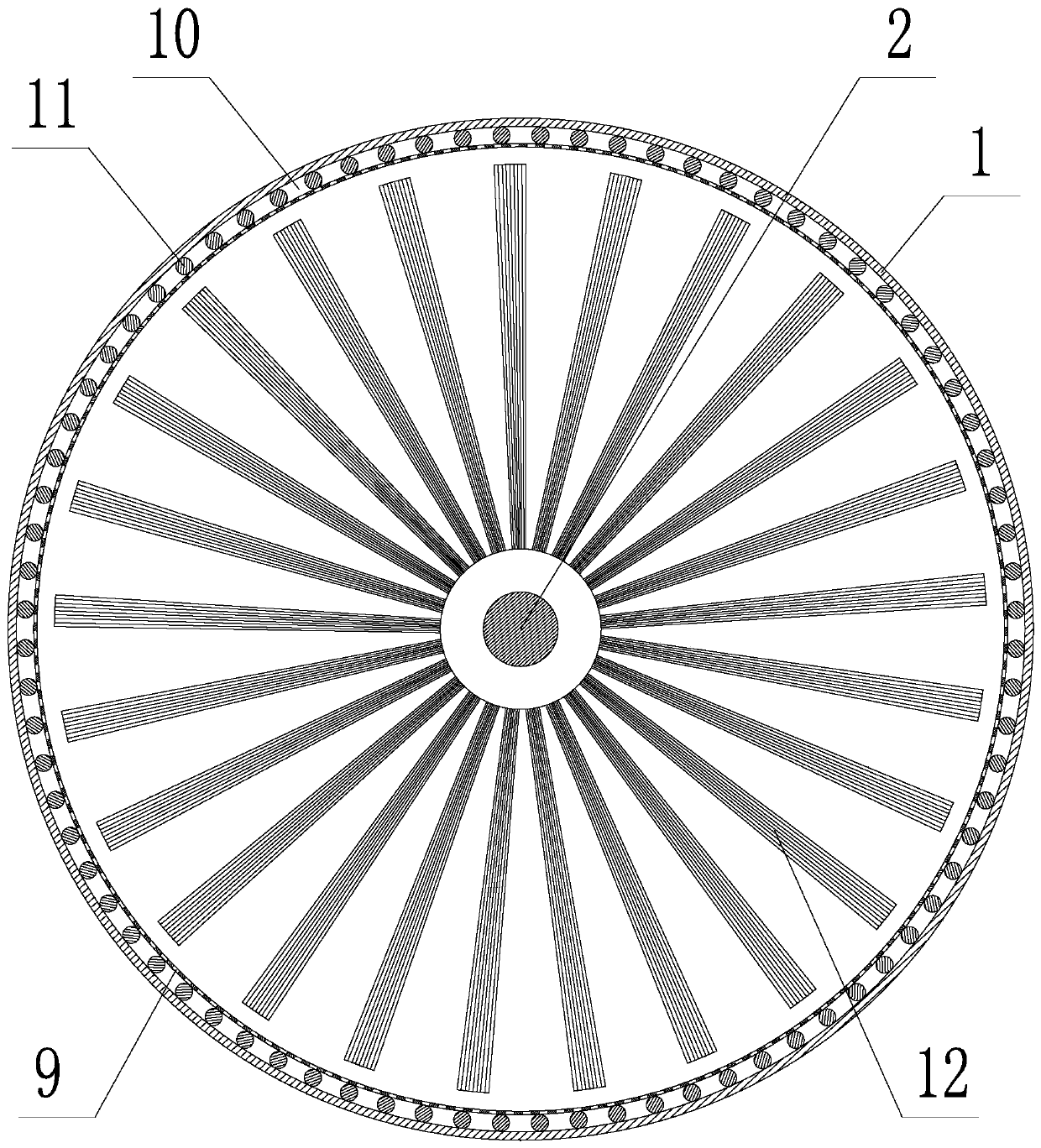

[0052] In this embodiment, the cylinder body 1 of the device has a diameter of 600mm, and the flue gas throughput is 6000m 3 / h, the brush 4 adopts a disk-type installation structure on the rotating shaft 2, and the number of brush disks 12 is four.

[0053] An active final purification method of industrial flue gas, which is used for demisting and saline-alkali soluble substances, the steps are:

[0054] ①. Establish a flue gas passage pipe (that is, the cylinder 1 in the device), set up a flue gas inlet in the lower part of the pipe (that is, the flue gas inlet 6 in the device), and set up a flue gas outlet in the upper part of the pipe (that is, the flue gas in the device export7);

[0055] ②. A shaft with a brush and capable of high-speed rotation is set up inside the pipeline (that is, the brush 4 and the rotating shaft 2 in the device, and the high-speed rotation of the rotating shaft 2 is realized by driving the motor 3 and the belt and pulley mechanism 5 );

[0056]...

Embodiment 2

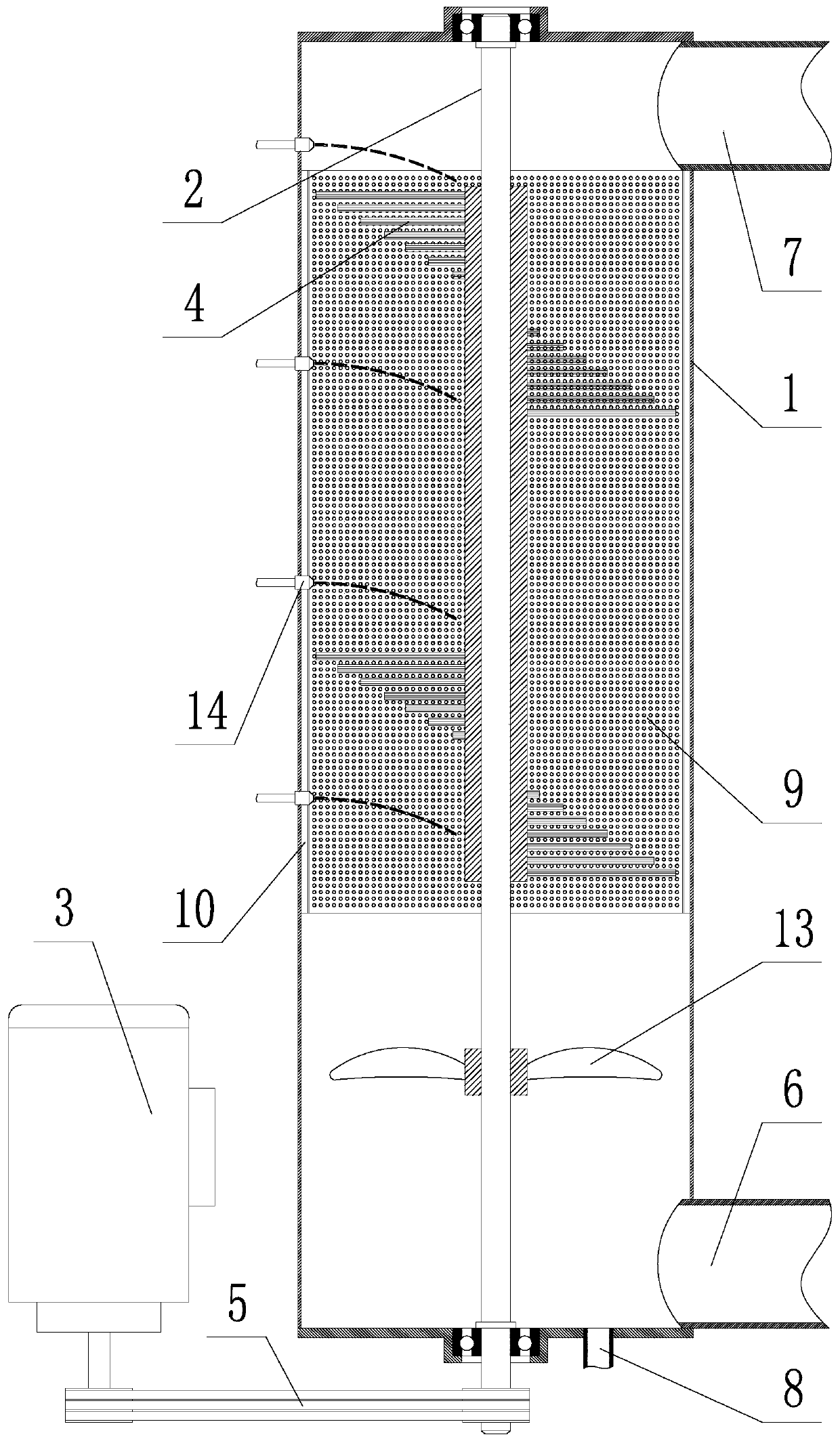

[0061] In this embodiment, the cylinder body 1 of the device has a diameter of 800mm, and the flue gas throughput is 8000m 3 / h, the brush 4 adopts a disk-type installation structure on the rotating shaft 2, and the number of brush disks 12 is four.

[0062] An active industrial flue gas terminal purification method for secondary desulfurization, the steps are:

[0063] ①. Establish a flue gas passage pipe (that is, the cylinder 1 in the device), set up a flue gas inlet in the lower part of the pipe (that is, the flue gas inlet 6 in the device), and set up a flue gas outlet in the upper part of the pipe (that is, the flue gas in the device export7);

[0064] ②. A shaft with a brush and capable of high-speed rotation is set up inside the pipeline (that is, the brush 4 and the rotating shaft 2 in the device, and the high-speed rotation of the rotating shaft 2 is realized by driving the motor 3 and the belt and pulley mechanism 5 );

[0065] ③, the flue gas is passed into the ...

Embodiment 3

[0069] In this embodiment, the cylinder body 1 of the device has a diameter of 1000mm, the flue gas throughput is 10000m3 / h, and the brush 4 adopts a spiral installation structure on the rotating shaft 2 .

[0070] An active final purification method of industrial flue gas, which is characterized in that it is used for secondary denitrification, and the steps are:

[0071] ①. Establish a flue gas passage pipe (that is, the cylinder 1 in the device), set up a flue gas inlet in the lower part of the pipe (that is, the flue gas inlet 6 in the device), and set up a flue gas outlet in the upper part of the pipe (that is, the flue gas in the device export7);

[0072] ②. A shaft with a brush and capable of high-speed rotation is set up inside the pipeline (that is, the brush 4 and the rotating shaft 2 in the device, and the high-speed rotation of the rotating shaft 2 is realized by driving the motor 3 and the belt and pulley mechanism 5 );

[0073] ③, the flue gas is passed into th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com