Track shot blasting device

A shot blasting device and crawler-type technology, which is applied to used abrasive treatment devices, abrasives, metal processing equipment, etc., can solve problems such as unfavorable energy saving, doping, delaying workpiece processing cycles, etc., to reduce production and maintenance costs. The effect of ensuring processing efficiency and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The content of the present invention will be described below in conjunction with specific embodiments.

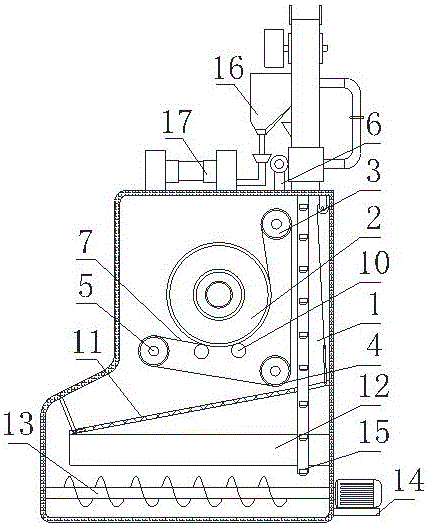

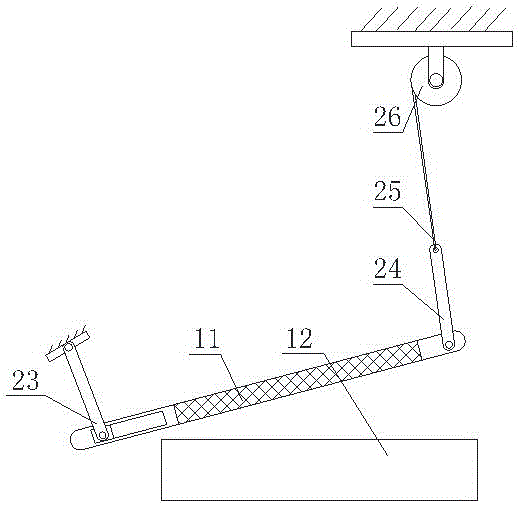

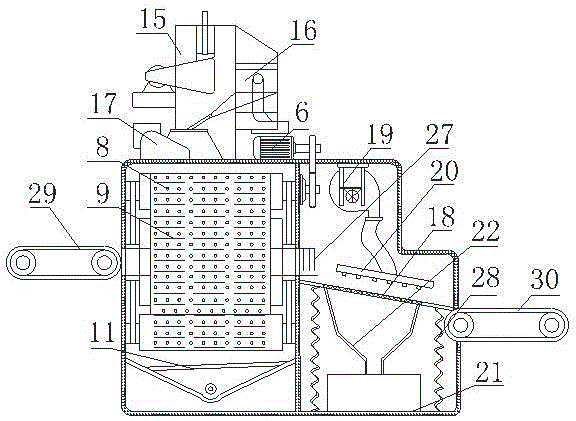

[0026] Such as Figure 1-Figure 4 as shown, figure 1 It is a side view of the crawler-type shot blasting device proposed by the present invention, figure 2 yes figure 1 Schematic diagram of the structure of the regulator assembly, image 3 It is the front view of the crawler type shot blasting device proposed by the present invention, Figure 4 yes image 3 Schematic diagram of the structure of the middle guide tube.

[0027] refer to Figure 1-Figure 4 , the crawler-type shot blasting device that the present invention proposes, comprises shot blasting chamber 1, and both sides of shot blasting chamber 1 inner wall are provided with rotatable disc 2, and disc 2 middle part is provided with through hole, wherein a through hole is feed inlet , the other through hole is the discharge port, a track 7 is provided between the two discs 2, and the track 7 is made of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com