Oil product filter device

A filter device and oil product technology, which is applied in the petroleum industry, processing hydrocarbon oil, and only multi-stage serial refining process treatment, etc., can solve the problems of affecting engine combustion performance, engine fuel injection nozzle blockage, engine work abnormality, etc. , to achieve the effect of simple structure, increased filtration capacity, economical and practical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

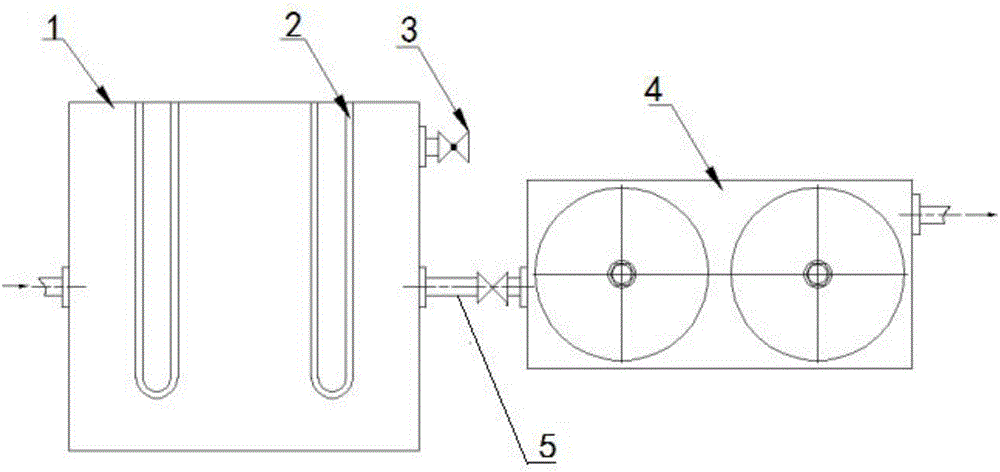

[0030] Such as figure 1 , 3 , 4, the present embodiment provides an oil filtering device, including a heating oil tank 1 and a filter 4, a heating device is arranged in the heating oil tank 1, an oil inlet port is provided on the side wall of the heating oil tank 1, and the heating oil tank 1 The upper part is provided with an air release valve 3; the heating oil tank 1 communicates with the oil inlet 15 of the filter 4 through the oil inlet pipeline 5, and the filter 4 includes an outer cover 11, a filter element 13 and a base 9, and the outer cover 11 is fixedly arranged on the base 9, The filter element 13 is placed in the outer cover 11 , and a magnet 14 is arranged in the filter element 13 , and the oil product is used for filtering by the filter element 13 and then discharged through the oil outlet 18 .

[0031] The heating device in the oil filter device is a heating tube 2, and there are multiple sets of heating tubes 2, which can quickly and fully heat the tire pyrol...

Embodiment 2

[0037] Such as figure 2 As shown, this embodiment provides an oil filter device, the structure of which is basically the same as that of Embodiment 1, except that:

[0038]In this embodiment, the oil filter device is provided with two sets of filters 4, each set includes two filters 4 arranged in series, and each filter set passes through the first communication pipeline 7, the second communication pipeline 8 and the oil inlet pipeline respectively. 5 are connected, and the first communication pipeline 7 and the second communication pipeline 8 are provided with on-off valves, and the oil inlet pipeline 5 is provided with a main valve 6 .

[0039] That is to say, the mode of one standby and one use is set in this embodiment. During the process of filtering work, two groups of filters are carried out by adjusting the opening and closing states of the switch valves on the first communication pipeline 7 and the second communication pipeline 8. Switching use of the filter 4; open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com