Technological method for producing gentamicin C1a through fermentation

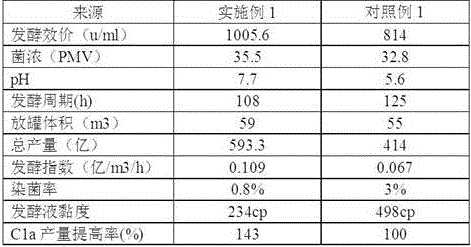

A process method, the technology of gentamicin, which is applied in the field of fermentation engineering, can solve the problems of high price of high-purity C1a, unclear determination of parameters and high extraction cost, etc., and achieve titer and fermentation The effect of increasing the index, shortening the fermentation and cultivation period, and shortening the fermentation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

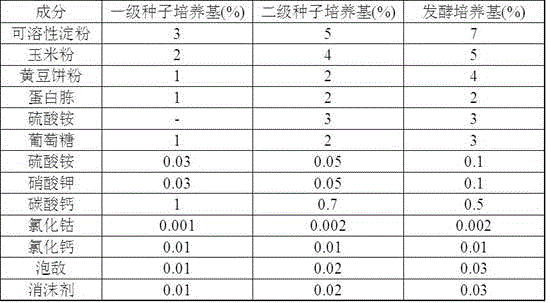

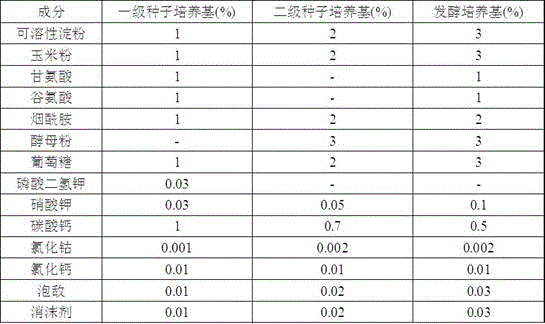

[0028] Prepare primary seed medium, secondary seed medium and fermentation medium according to the composition ratio in Table 1, and the prepared medium is sterilized by high-pressure steam for future use.

[0029] Inoculate the stored dormant Micromonospora for the production of gentamicin C1a on the slant medium for activation and culture, then scrape one or two slant spores with sterile water and pipette them Put the spore suspension into a sterile Erlenmeyer flask to prepare the spore suspension; put the spore suspension into a sterile small fermenter under flame protection, and cultivate it for 36 hours at a temperature of 36°C, a rotation speed of 200rpm / min and an air ratio of 7.5VVM to prepare Seed liquid.

[0030] Primary seed culture: at 2m 3 Add the first-level seed medium into the seed tank, use sterile air to keep the pressure, and then use the differential pressure gauge to inoculate 1L of the cultivated seed solution into the first-level seed tank. During the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com