Energy-saving fresh air treatment equipment

A technology for fresh air treatment and equipment, applied in mechanical equipment, lighting and heating equipment, ventilation systems, etc., can solve the problem of waste of condensed water resources, and achieve the effect of solving the problem of condensing water treatment and saving water sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

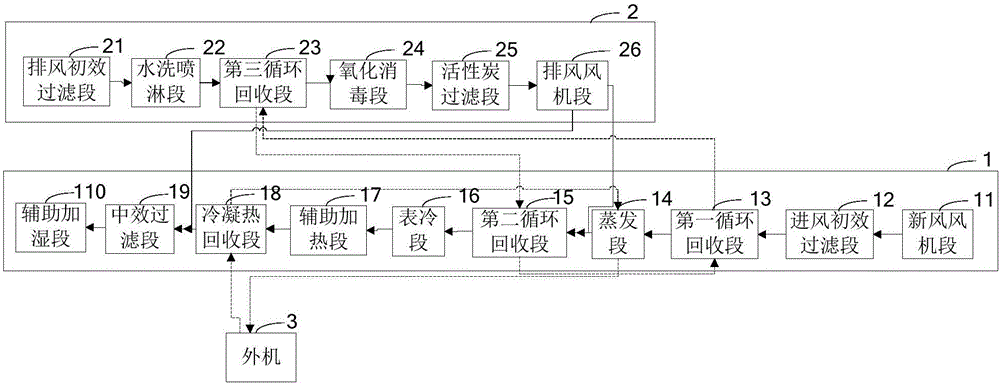

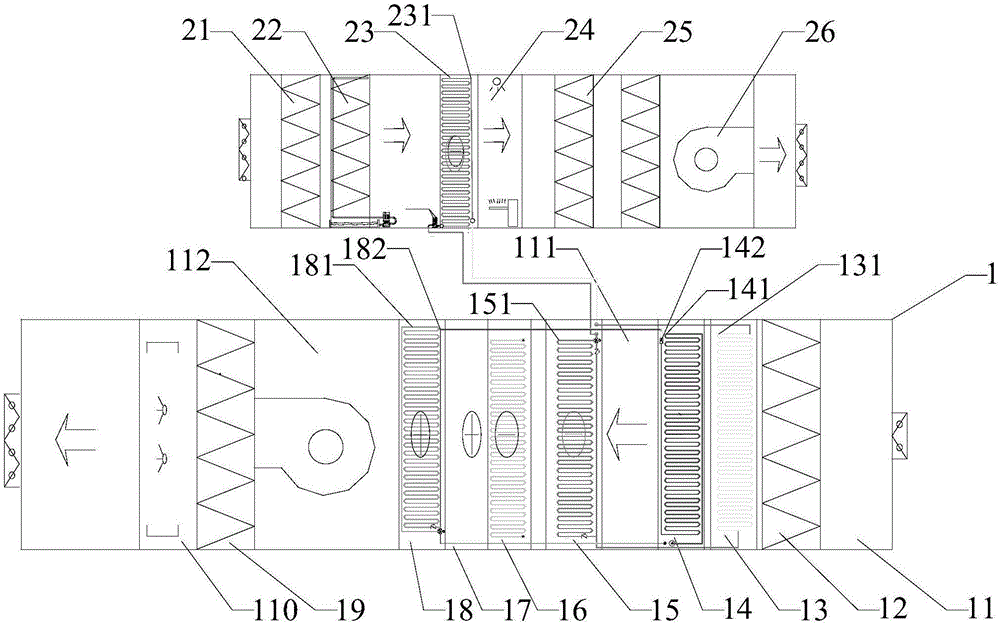

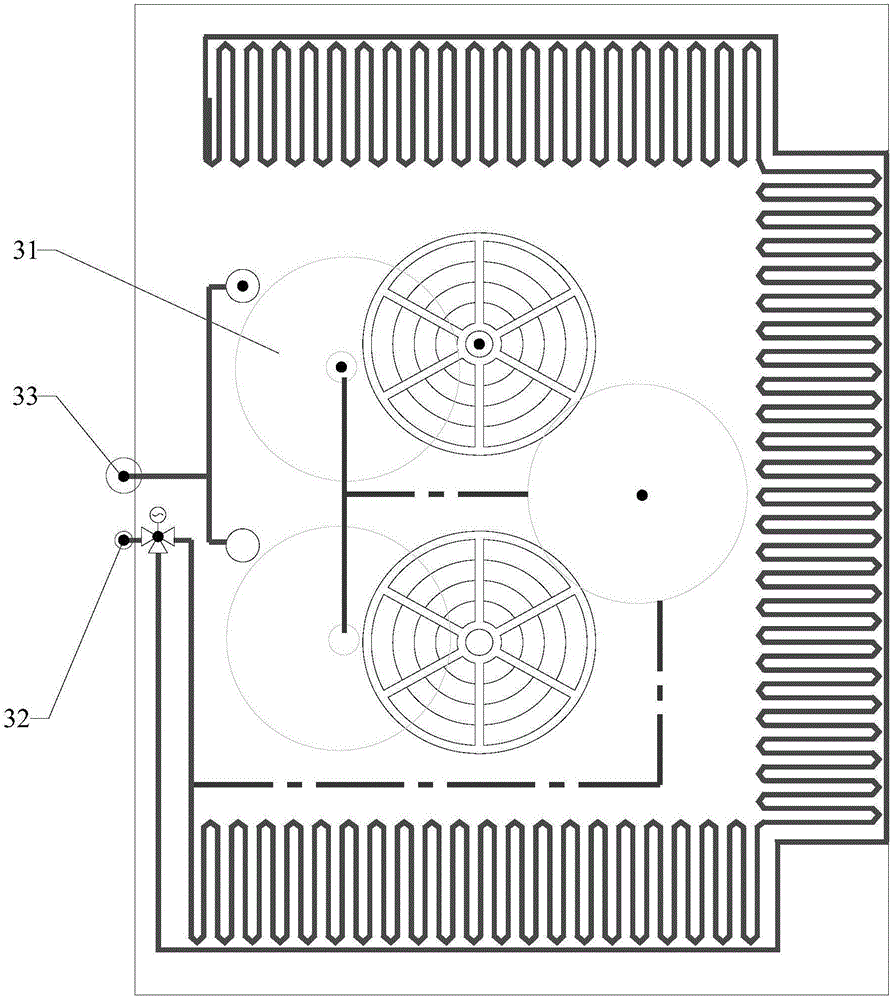

[0048] Please refer to Figure 1 to Figure 3 , an energy-saving fresh air device, including an external unit 3, an air inlet unit 1 and an exhaust fan unit 2;

[0049] The air intake unit 1 has the following structures and functions:

[0050] The air inlet unit 1 is arranged in sequence from the fresh air inlet end to the fresh air outlet end with a fresh air fan section 11, an inlet air primary filter section 12, a first circulation recovery section 13, an evaporation section 14, a second circulation recovery section 15, and a surface cooling section. Section 16, auxiliary heating section 17, condensation heat recovery section 18, mid-efficiency air inlet filter section 19 and auxiliary humidification section 110;

[0051] The fresh air fan section 11 is used to draw external fresh air into the air intake unit 1;

[0052] The primary air inlet filter section 12 is used for preliminary filtering of fresh air;

[0053] The surface cooling section 16 is connected to the centr...

Embodiment 2

[0091] On the basis of Embodiment 1, a reservoir is set at the bottom of the evaporation section 14, and an electric three-way valve for the spray section is set at the water inlet end of the washing spray section 22, and the electric three-way valve for the spray section is connected to the central controller. The first inlet end of the electric three-way valve of the spray section is connected to a tap water source, the second inlet end of the electric three-way valve of the spray section is connected to the reservoir at the bottom of the evaporation section 14 through a pipeline, and the electric three-way valve of the spray section The outlet end of the valve is connected to a spray pipe, the spray pipe is provided with a water washing spray pump, the reservoir is provided with a liquid level sensor, and the liquid level sensor includes a high water level sensor and a low water level sensor, so The liquid level sensor is connected to the central controller, and the bottom o...

Embodiment 3

[0094] According to a kind of energy-saving fresh air device described in Embodiment 1, a primary air return port 111 is added after the evaporation section 14, and a secondary air return port 112 is added after the condensation heat recovery section 18; The secondary air return system, the secondary air return system includes a return air duct connected behind the exhaust fan section 26, and the return air duct includes a return air main pipe, a primary exhaust duct branched by the return air main pipe and a secondary air return pipe , the primary air return pipe is connected to the primary air return port 111, and the secondary air return pipe is connected to the secondary air return port 112; the primary return air pipe, the secondary air return pipe and the return air main pipe are provided with a diverter valve at the diversion point, the said The air flow split by the primary return air duct is 30% of the air flow of the main return air duct, and the air flow divided by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com