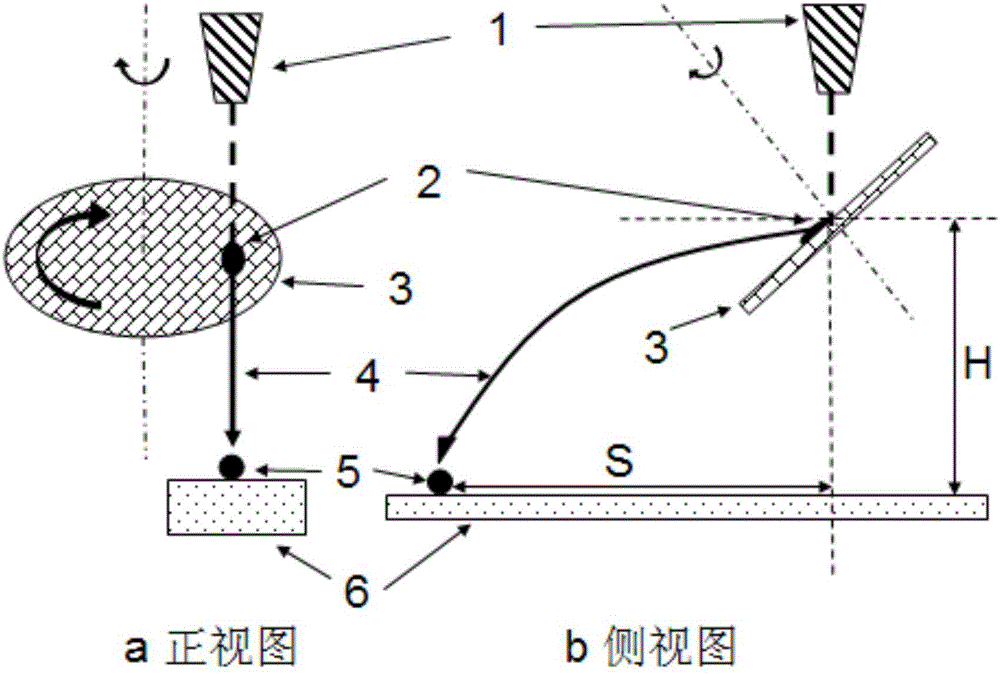

Method for testing striking-splashing performance of liquid on surface of inclined rotating disc

A test method, technology of rotating disk, applied in the field of solid surface wetting, can solve problems such as difficulty in forming amorphous metal strips, increased production costs, and splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

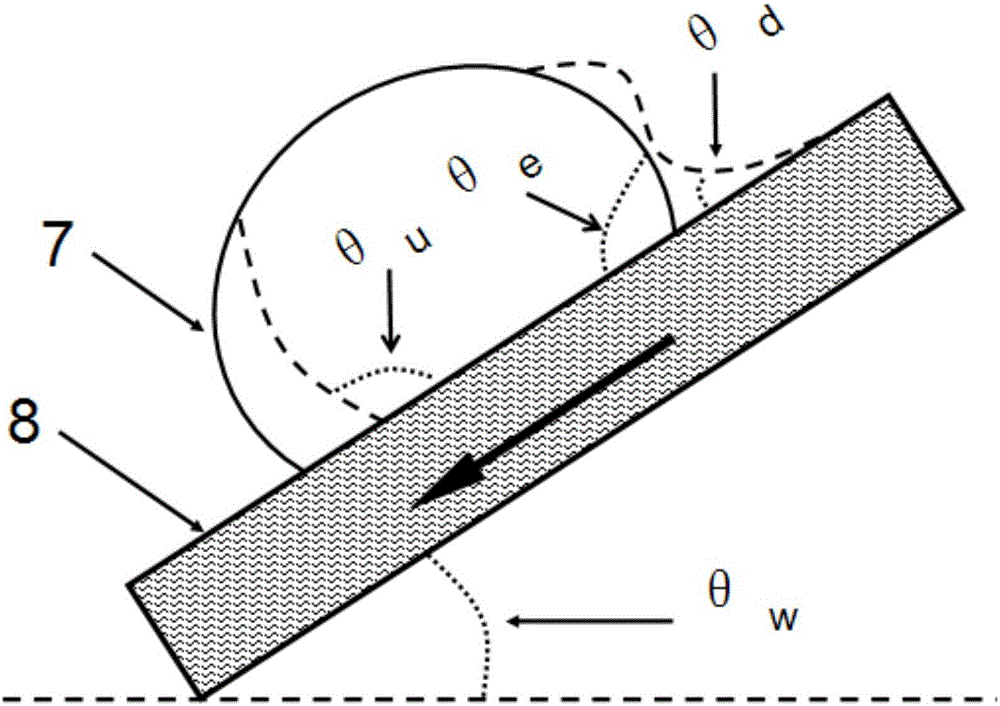

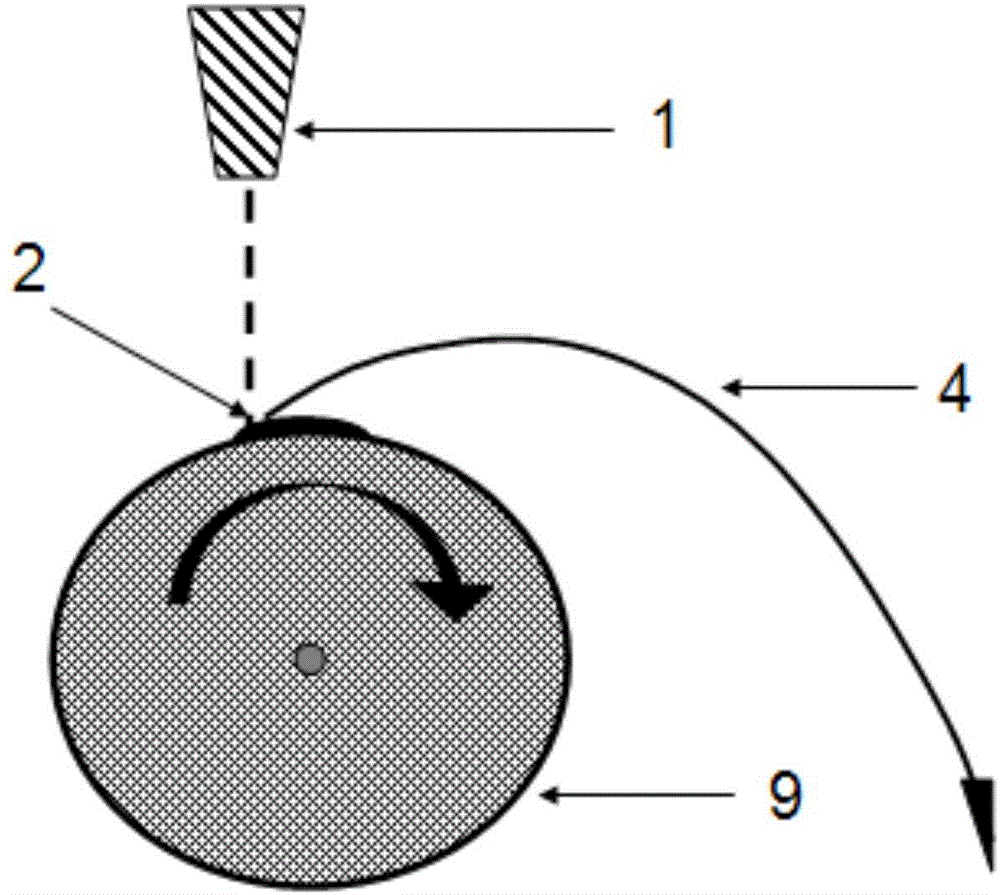

Method used

Image

Examples

Embodiment 1

[0032] The test conditions are as follows:

[0033] (1) Choose distilled water, choose alloy aluminum rotating disk for rotating disk, and polish the surface of rotating disk with No. 200 sandpaper.

[0034] (2) Control the temperature of the rotating disk to 60°C.

[0035] (3) Control the rotation speed of the rotating disk at 1000 revolutions per minute.

[0036] (4) Control the tilt angle of the rotating disk to 10°.

[0037] (5) The droplet falling speed is 5 meters / second.

[0038] The test result shows that the farthest splash distance of the splash droplet is 525 mm.

Embodiment 2

[0040] The test conditions are as follows:

[0041] (1) The rotating disk is a brass rotating disk, and the surface of the rotating disk is polished with No. 800 sandpaper.

[0042] (2) Choose metal gallium (melting point 29.8℃), control the droplet generator to make the metal gallium temperature 80℃

[0043] (3) Control the temperature of the rotating disk to 200°C.

[0044] (4) Control the rotation speed of the rotating disc to 20 revolutions per minute.

[0045] (5) Control the tilt angle of the rotating disk at 30°.

[0046] (6) The droplet falling speed is 20 m / s.

[0047] The test result shows that the farthest splash distance of the splash droplet is 1243 mm.

Embodiment 3

[0049] The test conditions are as follows:

[0050] (1) The rotating disc is made of steel, and the surface of the rotating disc is polished with No. 2000 sandpaper.

[0051] (2) Select metal tin (melting point 231.9℃), and control the droplet generator to make the metal tin temperature 270℃

[0052] (3) Control the temperature of the rotating disk to -10°C.

[0053] (4) Control the rotation speed of the rotating disc to 300 revolutions per minute.

[0054] (5) Control the tilt angle of the rotating disk at 20°.

[0055] (6) The droplet falling speed is 50 meters / second.

[0056] As a result of the test, tin solidified on the surface of the rotating disk, and the farthest splash distance was recorded as "none".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com